(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

1095 steel is one of the old and popular steel options in the world of knives and tools. Several branded and custom knife makers use it to make a variety of knives, including swords and the Japanese katanas. For new knife makers, it is often recommended as ‘the steel to go for!’

In this post, let’s discuss this steel to determine whether it is a good option for your knife’s build material.

What is 1095 Steel?

Also known as cutlery spring steel, 1095 is a simple form of carbon steel made up of two alloying components, namely, manganese and carbon. It belongs to the 10xx category of steels, which are widely used in making knives and katanas. It is genuinely a high-carbon steel type; it is not stainless steel. Still, it is admired for its significant level of sharpness as well as commendable ability to maintain it.

Often expressed as old and simple, 1095 is a well-established steel grade. Although it is difficult to find out when it was made, it is easy to conclude that it is fairly old. This is because there is no standard long list of components tagged as modern versions. Its simple composition indicates that it is among the earlier steels. There is no need of twisting its composition to get rid of patent problems and conflicts.

The steel has been in use for a long time. In the old days, it was widely used for making kitchen knives and pocket knives. Today, it is widely used in making fixed blade survival and bushcraft knives due to its ease of sharpening and high toughness level. This carbon steel is also preferable by many knife makers.

Anyways, this steel version has established itself as a trustworthy build material for cutlery. It can easily withstand regular use as well as is easy to sharpen. Nevertheless, as it is not stainless steel, corrosion resistance is likely to be unsatisfactory if not maintained or used properly.

Composition

1095 steel is named so because of the 10-series (10XX) naming process, in which the initial two digits indicate the two main components and the last two digits represent the amount of carbon content.

Thus, in the term 1095, 1 indicates carbon, 0 indicates the absence of the second main alloying component, 95 indicates 0.95% carbon. It is worth noticing that there is no other element present in the alloy to make this steel. Following are the various elements of which this steel is made up of:

- 0.95% carbon ensuring enhanced hardness and resistance to corrosion as well as wear

- 0.5% manganese ensuring boosted hardness and brittleness

- 0.03% phosphorus ensuring more strength

- 0.05% sulfur ensuring improved machinability

As 1095 is chiefly made using carbon and manganese, it is a quite hard, high-carbon steel type. Typically, its carbon content can range from 0.9% to 1.03%. However, it is not a true tool steel type. For any steel to qualify as tool steel, it must have alloy additives as well as much more than 1% of carbon modifying the steel’s behavior.

Hardness

The hardness level for this steel varies, as its carbon content and manufacturing process can differ slightly. Typically, the hardness level is between 55 and 58 HRC. However, in the case of some makers, it can be as high as between 64 and 65 HRC.

1095 Carbon Steel Properties

The chemical composition of this carbon steel governs its properties. Following are its most significant properties that you can expect:

- Strongly Sharp: This is one of the main pros of the 1095 steel. It can get quite sharp, as it is an easy type of steel to work with. Even the treated as well as coated ones ensuring increased hardness are manageable when it is the matter of sharpening.

- Good Edge Retention: 1095 carbon steel can hold its sharpness well, although not as long as any very hard steel. In other words, its blade will become dull after a while due to regular use.

- Great Sharpening Ease: This counterbalances the issue of not-so-long edge retention. As the steel is not that hard, it is easy to sharpen. This appeals to hobbyists and other users who want a hassle-free maintenance process.

- Good Wear Resistance: The good level of hardness of this steel due to high carbon ensures good resistance to abrasion and wear. It is not the best resistance as compared to other varieties of steel, but it is capable enough to endure outdoor use, provided you select a well heat-treated blade.

- Good Toughness: A 1095 steel blade that is heat-treated well functions as reliable choppers without the risk of chipping and breaking. 1095 survival and bushcrafting blades will hold up well while batoning wood. A few may say that this steel is not this tough, but a well-treated one can be! Although not as tough as super steels, this steel can be considered tough considering the purposes for which it is used. Thus, it is important to know the type of heat treatment makers employ in making their 1095 blades. Despite good wear resistance, the low level of manganese makes this steel less tough than other types of steel. While manganese hardens the metal when present in a certain quantity range, it also makes it more brittle.

- Rust-resistance: Due to no chromium, this steel can easily rust if not lubricated or kept dry. However, 1095 blades usually have some layer of coating to keep rusting at bay, provided you take good care of the blade. Thus, the rusting issue gets eliminated.

- Brittleness: This steel is more brittle than other steel types, due to which it is preferable for making thick or not-too-thin blades. If used for making thin blades, they are likely to break easily. Thus, it is not used for making tools, sushi knives, and folding knives. When heat-treated, the strength or hardness of 1095 also increases, but it is likely to get brittle too.

Comparison with Other Knife Steel Options

1095 vs Stainless Steel

1095 is a better choice if you prefer extra hardness and sharpness. On the other hand, stainless steel is ideal for those who want an anti-corrosive and lasting blade. Stainless steel has approximately 10% chromium that contributes to the aforementioned properties. However, its blades are not as sharp as the high-carbon ones.

1095 vs 1055

Due to less carbon content, 1055 is somewhat softer than 1095. The latter wins in terms of toughness and edge retention.

1095 vs 1084

The latter is considered as the former’s equivalent, and both of them deliver an identical performance in the areas of sharpening ease, toughness, and corrosion resistance. However, 1084 ensures a bit better edge retention ability as well as more hardness. Thus, it is more resistant to wear than 1095.

1095 vs 1075

Here, 1095 wins in terms of hardness and better edge retention ability due to more carbon content. On the other hand, 1075 is easier to sharpen and is tougher.

1095 vs 5160

As a very popular forging steel, 5160 is a high-end steel type. It contains chromium to ensure more hardness and better corrosion resistance. It also wins over 1095 in terms of toughness. 5160 steel is ideal for tough-use knives and swords; whereas, 1095 steel is ideal for making tough knives at a more competitive cost.

1095 vs SK5

The Japanese SK5 high-carbon steel is similar to 1095 but has little chromium. Still, it is non-stainless. Nevertheless, SK5 is harder with a rating of 65 HRC and ensures better edge retention as well as wear resistance than 1095.

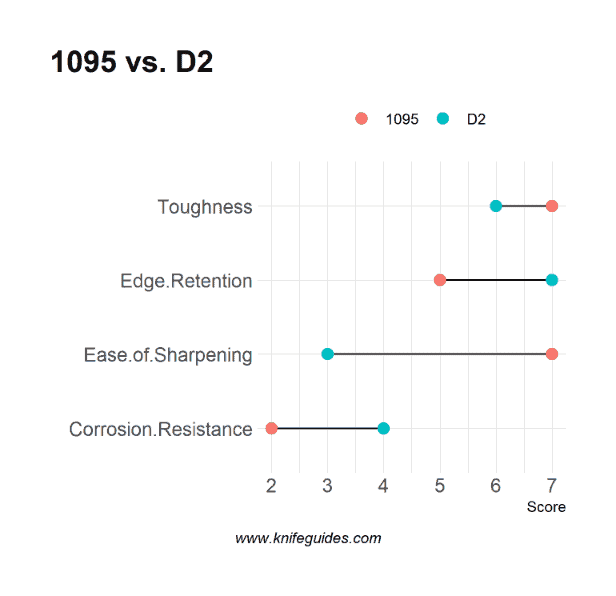

1095 vs D2

With high chromium as well as carbon content, D2 ensures better hardness, wear resistance, corrosion resistance, and edge retention than 1095. On the other hand, it is easier to sharpen and is more affordable than D2.

1095 vs W2

Both these carbon steels have similar components but they are not identical. Both have a low corrosion resistance but W2 is a bit tougher and harder than 1095.

Top 1095 Knives

| Image | Title | Price | Prime | Buy |

|---|

So, is 1095 Carbon Steel Good for Your Knives?

1095 is an old and affordable steel option that has good hardness, toughness, machinability, and great edge sustenance ability. For beginners, the steel is easy to sharpen and is quite sharp. Many esteemed brands continue to use 1095 steel for knives despite its low level of corrosion resistance. Although this steel is prone to rust, proper oiling and dry storage will keep this risk at bay.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.