(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

154CM knife steel is one of the oldest steel variants available in the market. With a long, rich history spanning over a few decades, it ranks among the widely used steels for making various knives, ranging right from small folders to big fixed ones.

What is 154CM Steel?

154CM is a high-carbon, high-alloy, futuristic stainless steel made in America by Crucible Industries. It surfaced to fulfill the need for steel in applications that involve producing higher temperatures. This was where 52100 steel was proving to be inapt.

Indeed, it is usually tagged as a modified 440C version, chiefly distinguished by the inclusion of molybdenum. It is ideal for those who require a steel variant with better wear and corrosion resistance and more hardness than 52100.

The letters CM in the steel represent Climax Molybdenum, the name of a company that made the steel for the first time and then sold it to Crucible. The digits have no genuine interpretation, though.

Initially, 154CM was made for making the components of jet engine turbines. However, since the 1970s, it has been used widely for making knife blades.

After some time, Crucible manufacturers ceased using the vacuum-melted process for producing the steel. Unfortunately, this resulted in inferior quality. So then, many knife makers started using ATS-34, a Japanese equivalent of 154 CM. Later, Crucible began its production again and then came up with a CPM form, CPM 154.

154CM and CPM 154 are not the same, although they share many common aspects. Structurally, CPM154 is a powder steel form of the former.

Chemical Composition

The steel has enough chromium to be classified as stainless steel. It also has a high share of carbon and molybdenum. Following are the various elements of which this steel is made up of:

- 14% chromium for better tensile strength, resistance to corrosion as well as wear, and retention of sharpness

- 4% molybdenum for better strength as well as manufacturing ability (machinability)

- 1.05% carbon for enhanced hardness, durability, as well as resistance to wear and corrosion

- 0.8% silicon for better strength and toughness

- 0.5% manganese for improved hardness and sharpness retention

- 0.4% vanadium for better hardenability as well as wear resistance

- 0.4% tungsten for better wear resistance and hardness

- 0.03% phosphorus for better strength

- 0.03% sulfur for easier processing while manufacturing

This composition is similar to that of many other high-carbon stainless steel variants made around the second world war era. Only a few minor differences exist to get rid of patent problems.

Steel Hardness

Due to higher carbon, vanadium, and chromium content, 154CM boasts a rating of 58-61 on the Rockwell hardness scale. This makes it quite harder than several other stainless-steel options. As a result, it retains a sharp edge for much longer than these steel variants. In addition, the level of toughness goes up when this steel is double-tempered.

Steel Properties

The chemical composition of this steel contributes to its properties.

- Decent Toughness: This high-carbon steel is tough. Although the high hardness reduces the level of toughness, this steel is fairly tough. For you, it means that a 154CM blade can handle abuse in any application. It can endure quite a bit of impact and force. It is durable!

- Superb Edge Retention: This steel holds up its sharp edge for an unbelievably long time due to its chemical composition consisting of solid materials. This means a significantly reduced frequency of sharpening. So if you sharpen it once, the sharpness will last for a long time.

- Ease of Sharpening: It is fairly easy to sharpen such hard steel and attains razor-like sharpness quicker than most steels with an identical hardness level. Just do not allow it to become full dull, as then re-sharpening it can be pretty tough.

- Great Wear Resistance: This hard steel keeps wear and tear away. The credit goes to the high carbon and chromium levels along with manganese and vanadium that further fortify it. This makes it an ideal choice for making cutlery as well.

- Corrosion Resistance: As this is a type of stainless steel, it fights well against corrosion and rust. However, it is still prone to rust if you do not take its proper care. For example, those frequently touched regions on your knife can gather grime and sweat with time, which can attract an accumulation of rust. Thus, it is essential to maintain your blade dry and clean once you use it.

154 CM vs. Other Knife Steel Options

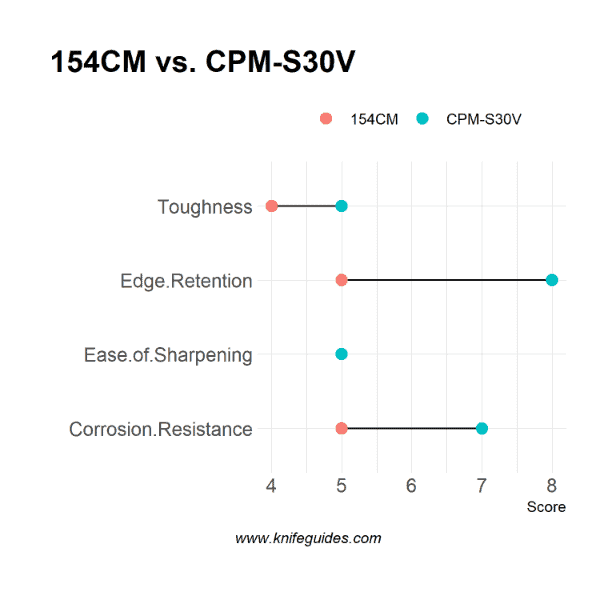

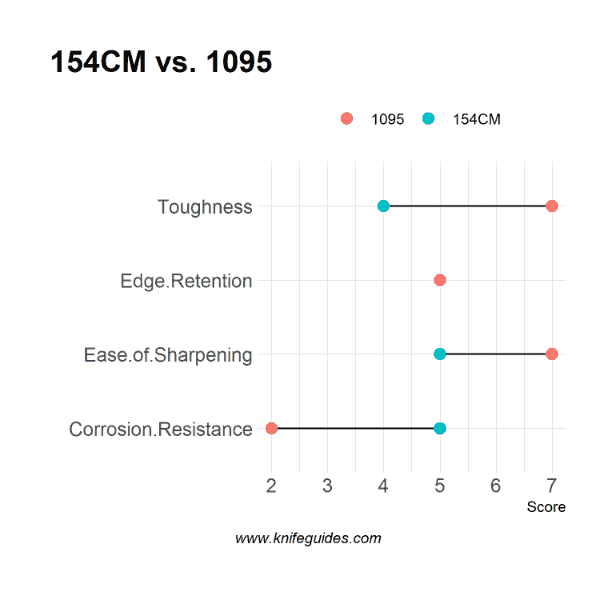

154CM vs. S30V

The latter is another martensitic form of stainless steel from the company that also produces 154 CM.

As S30V belongs to high-end steels, its performance is much better. S30V is harder and retains a sharp edge better. It is also better at corrosion resistance. However, S30V is costly. Still, depending on the heat treatment, S30V may come at affordable prices.

154CM vs. 440C

The latter is the closest steel variant, as it is a modified form of the former. It is alleged that 440C was the starting point for the preparation of 154CM as a 52100 alternative. Both these steel variants are almost close when it comes to all main properties.

Nevertheless, 440C has more chromium, while 154CM has more molybdenum. This balances the hardness and corrosion resistance equation for both.

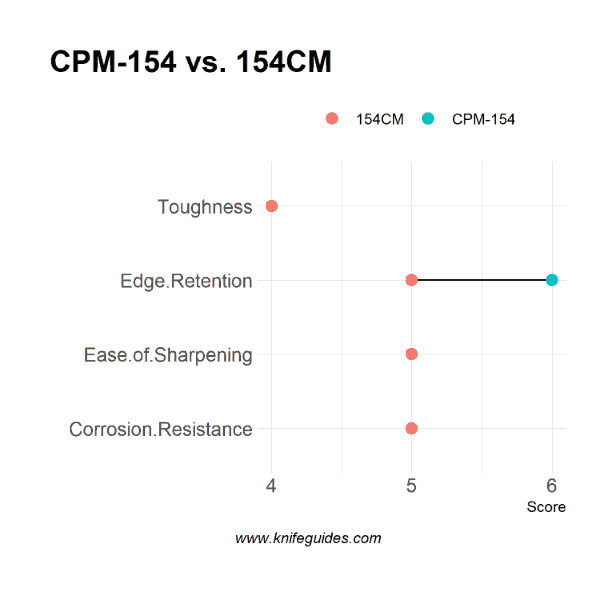

154CM vs. CPM 154

Both are quite similar steel variants. However, CPM 154 is a modern form of 154CM. It resolves a few issues of the original, especially at the time of polishing. With the chemical composition of CPM154, it is easier to polish and finish. With heat treatment, the CPM version is likely to give you better quality and performance.

CPM 154 is better in edge retention ability, while both score the same for other properties.

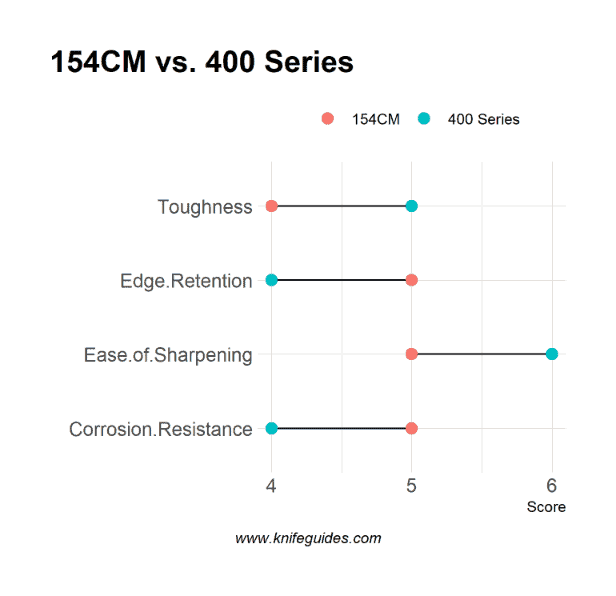

154CM vs. 1095

Both these steel variants differ significantly in composition. Although tougher and easier to sharpen, 1095 is susceptible to rust and corrosion because of no chromium content.

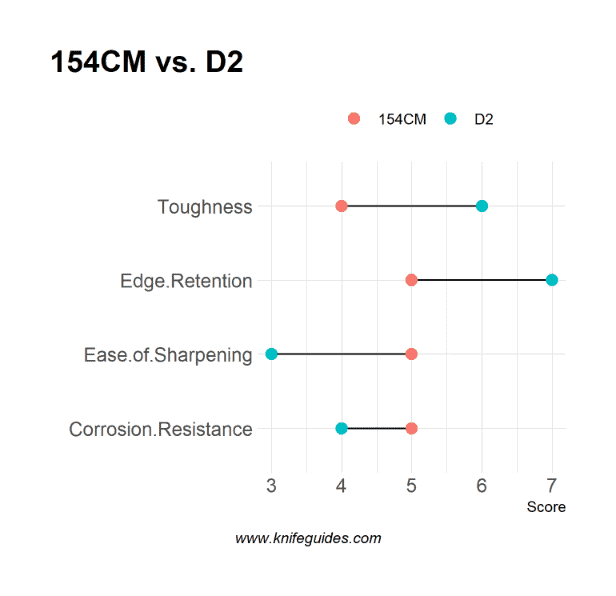

154CM vs. D2

The latter is also a mid-range, semi-stainless steel, admired for its hardness, edge sustenance, and wear resistance. However, when it comes to price, D2 is costlier. However, 154CM is better at resisting rust and corrosion and is easy to sharpen. But D2 wins in terms of toughness and edge retention.

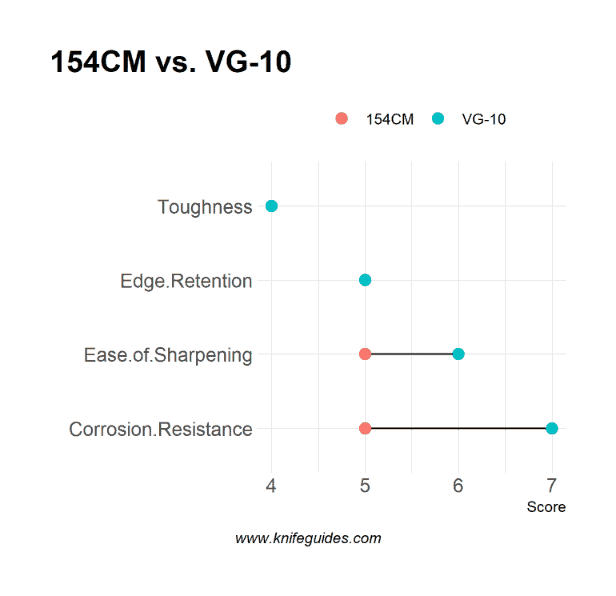

154CM vs. VG10

The latter is a famous kitchen knife steel. Both are pretty similar but have trivial differences in composition, especially in their chromium and carbon proportions. This makes VG10 somewhat a better option for those who want better corrosion resistance and ease of sharpening.

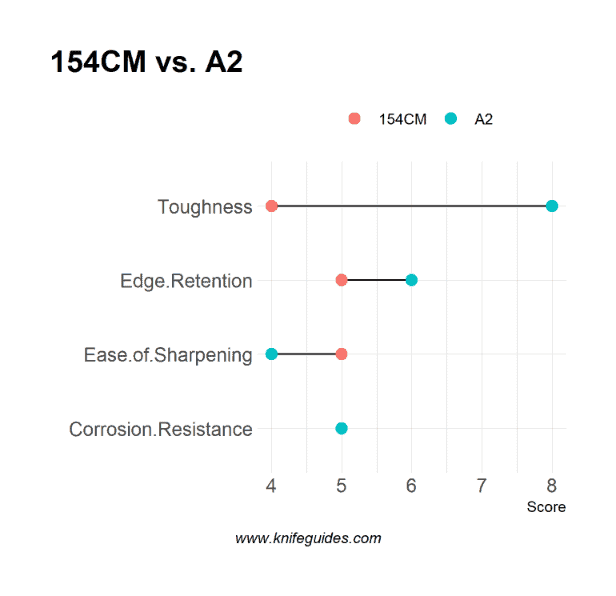

154CM vs. A2

Both of these belong to mid-range steels. A2 is known for its very high toughness, yet better at edge retention compared to 154CM. The corrosion resistance is almost the same for both.

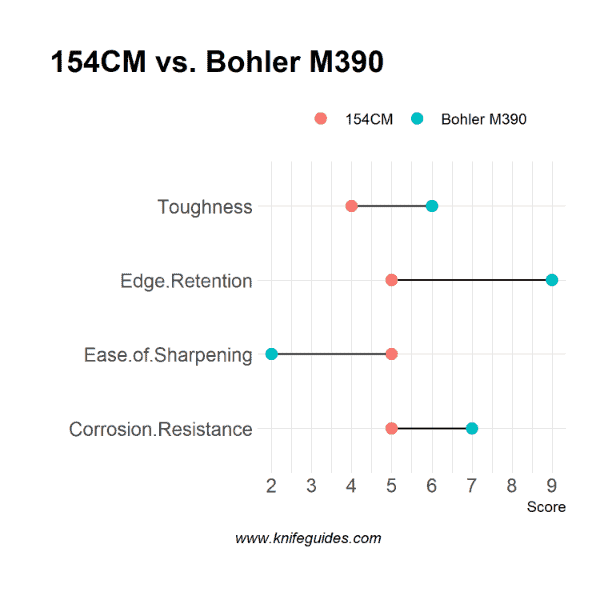

154CM vs. M390

Bohler M390 is a super steel found in knives costing $200 and upwards, whereas the former is a mid-range one. It beats 154CM in every single aspect except ease of sharpening. M390’s edge retention is unmatchable yet it is fairly tough. It scores excellent in corrosion resistance as well.

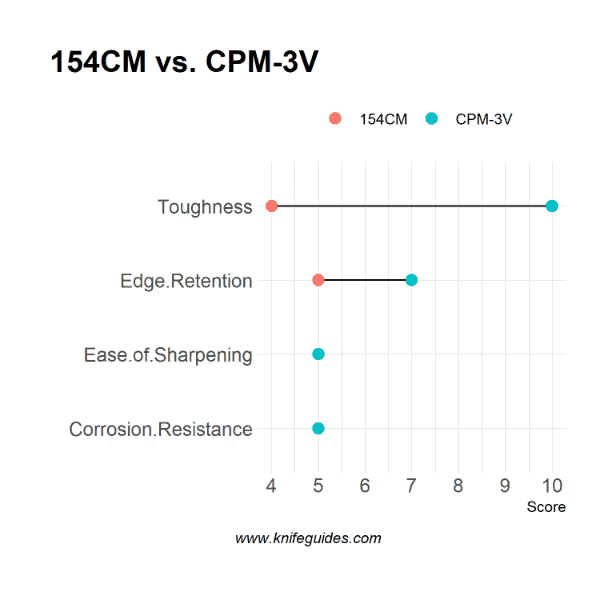

154CM vs. CPM-3V

CPM-3V is a costlier option. It is known for its very high toughness yet scores higher on edge retention in comparison to 154CM. In terms of corrosion resistance and edge retention, they score almost the same.

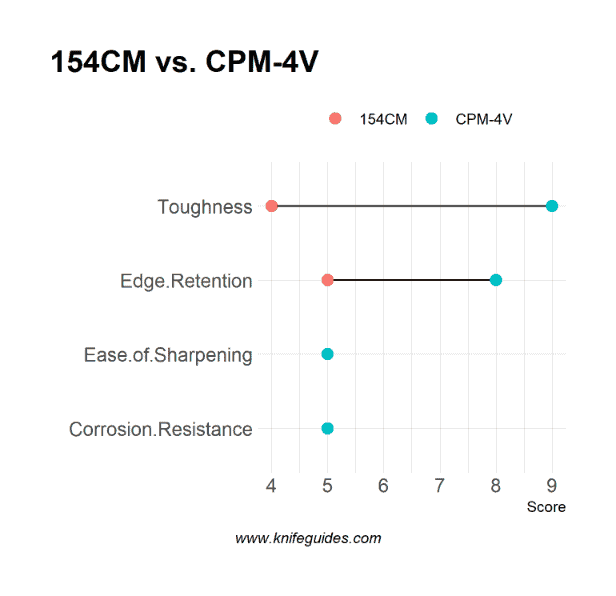

154CM vs. CPM-4V

The CPM-4V is an improved version of CPM 3V, we discussed above. It scores far better at toughness as well as edge retention compared to 154CM.

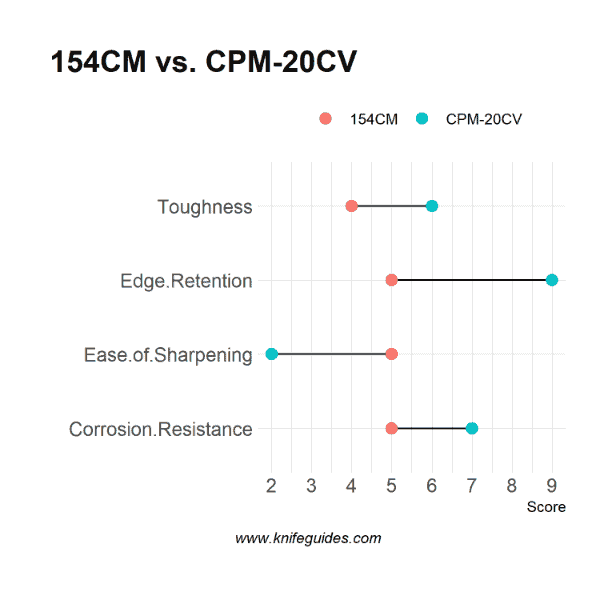

154CM vs. CPM-20CV

CPM-20CV is a premium steel that is only found in expensive knives. It beats 154CM in every single aspect except ease of sharpening. 20CV‘s edge retention is unmatchable yet surpasses 154CM in toughness. It also scores higher in corrosion resistance as well.

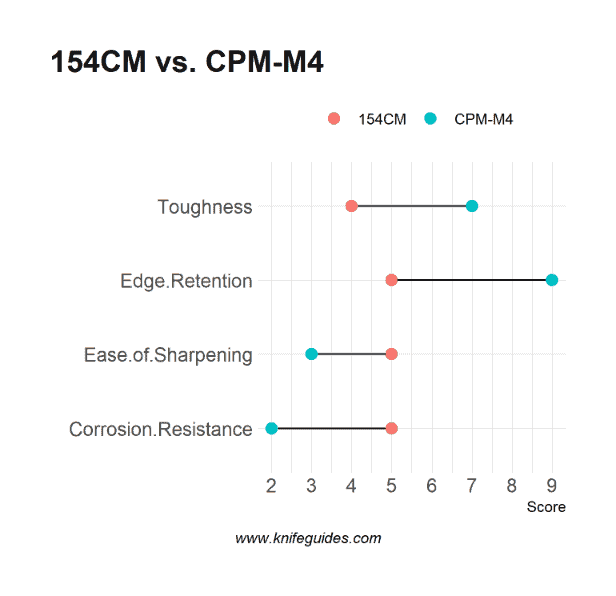

154CM vs. CPM-M4

CPM-M4 is a super steel, usually found in costlier knives. In terms of toughness and edge retention, it beats 154CM with a huge margin. However, this comes at a cost – poor resistance to corrosion, where the mid-ranged 154CM outperforms the M4.

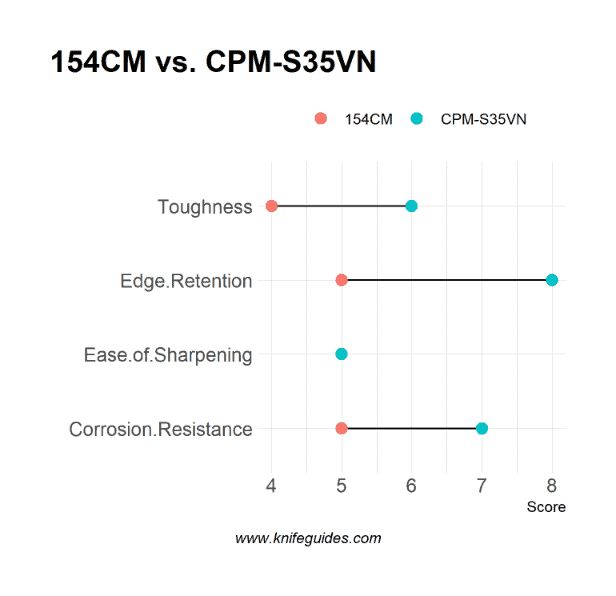

154CM vs. CPM-S35VN

CPM-S35VN is the upgraded brother of S30V with better toughness yet retaining its excellent edge retention and corrosion resistance. It beats 154CM in every single aspect.

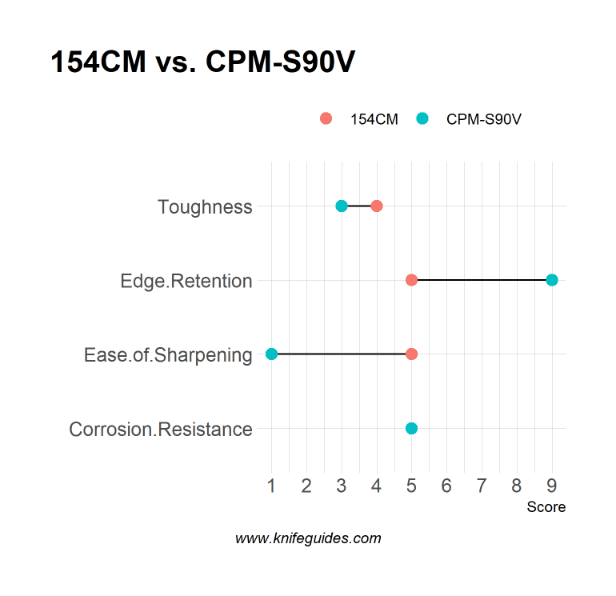

154CM vs. CPM-S90V

s90v belongs to premium steels. It’s known for its extremely high edge retention, hence an absolute pain in sharpening. 154CM is pretty close in scores to S90V in terms of toughness and corrosion resistance.

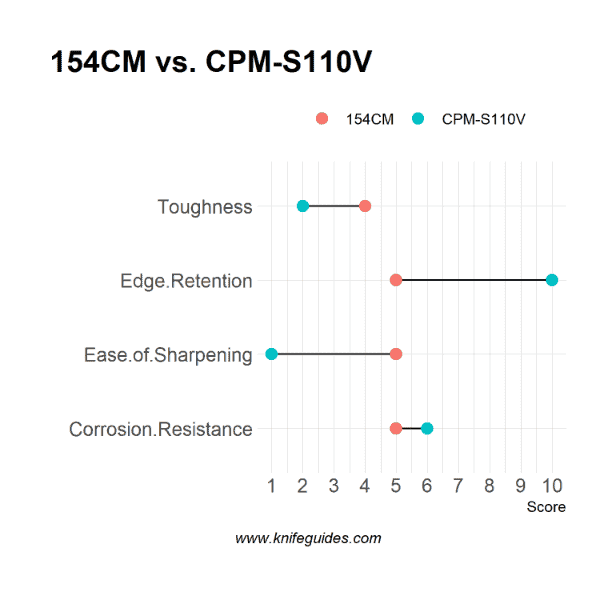

154CM vs. CPM-S110V

S110V belongs to the category of premium steels. It sets the limits to edge retention, hence performs poorly in terms of ease of sharpening and toughness compared to 154CM.

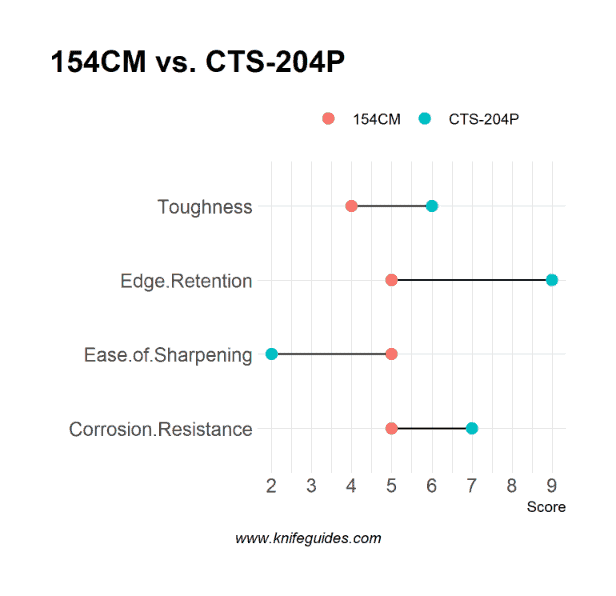

154CM vs. CTS-204P

CTS-204P is another premium steel that outperforms 154CM in every single aspect except ease of sharpening.

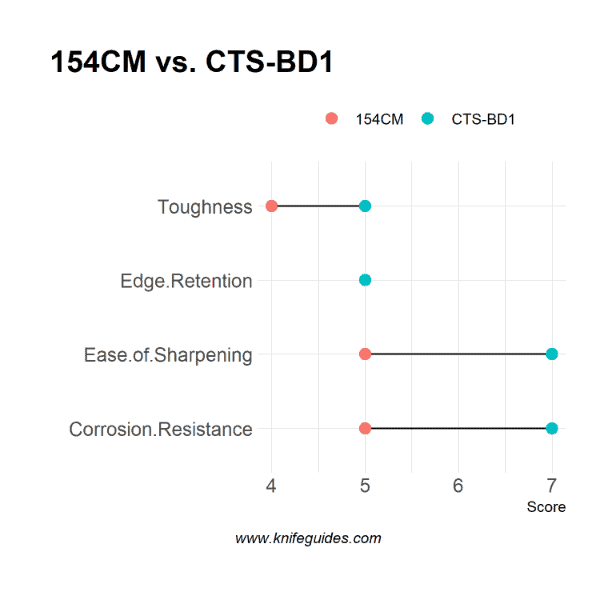

154CM vs. CTS-BD1

CTS-BD1 is an excellent entry-level steel and yet beats the 154CM steel in every aspect, although in a close race. It is also easier to sharpen and is quite corrosion-resistant.

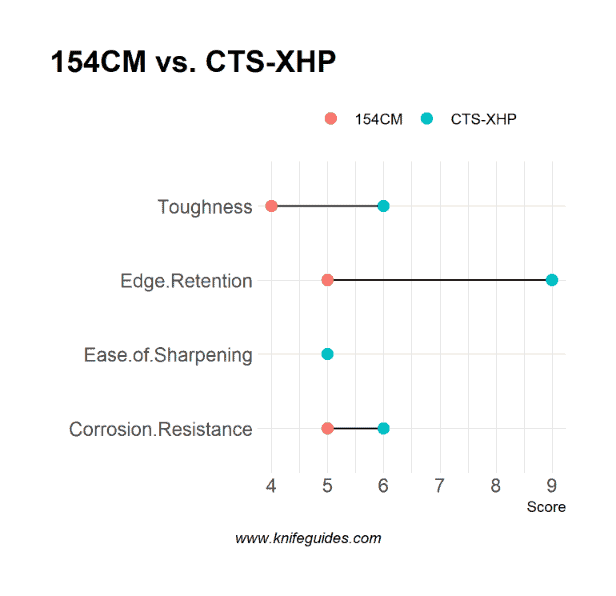

154CM vs. CTS-XHP

CTS-XHP belongs to the category of high-end steel. It is known for its very high edge retention property and beats 154CM in every single aspect.

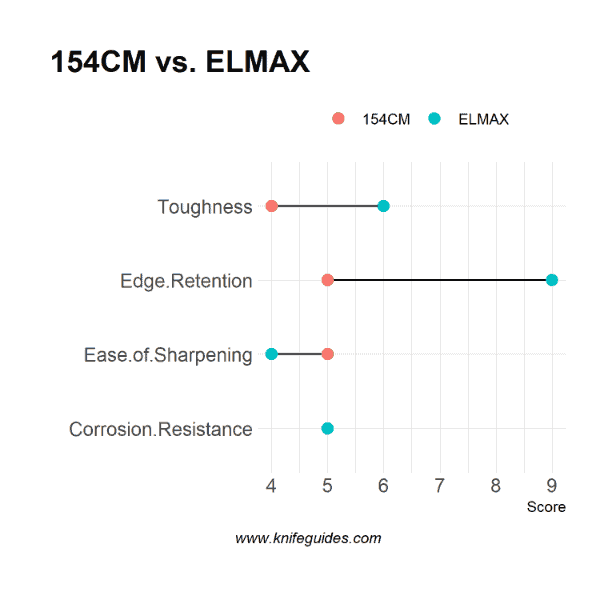

154CM vs. Elmax

Elmax is a great super steel found in costly knives. Thus, its edge retention and toughness are far better than that of 154CM.

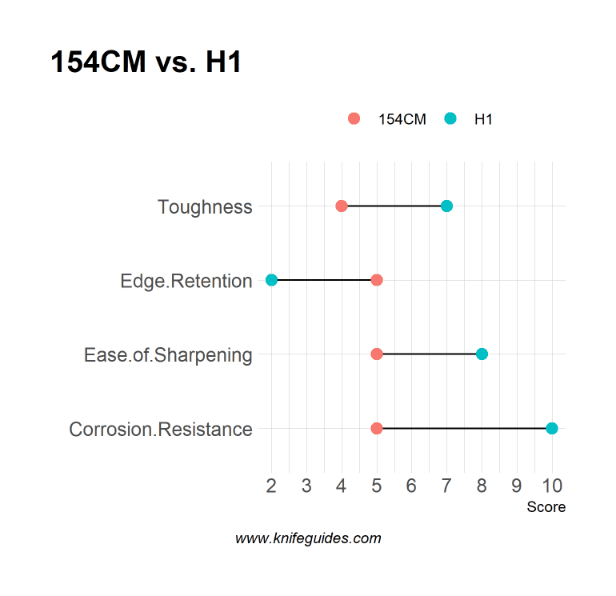

154CM vs. H1

H1 is a specialty steel known for its superior corrosion resistance. You can find it in most knives intended for saltwater applications. However, this comes at the cost of poor edge retention. Thus it fares better than 154CM in toughness as well as ease of sharpening.

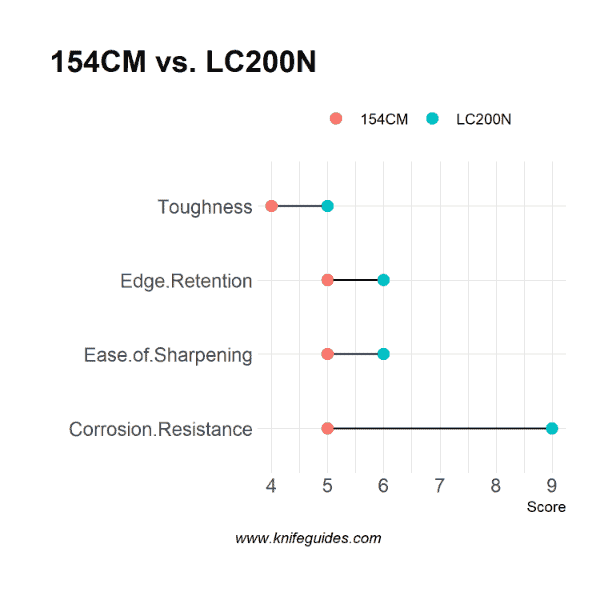

154CM vs. LC200N

LC200N is a high-end steel with exceptional corrosion resistance. It is another steel that beats 154CM in every single aspect.

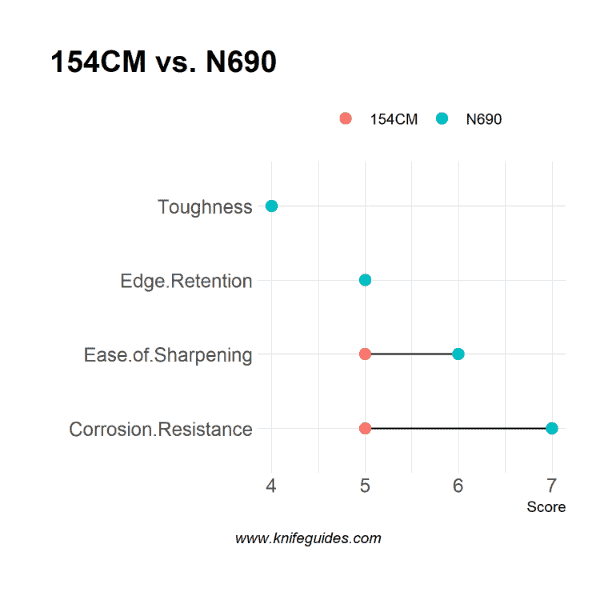

154CM vs. N690

Bohler N690 is a popular steel among knifemakers in Europe. It has a similar performance with 154CM in edge retention and toughness, but N690 fares better at corrosion resistance.

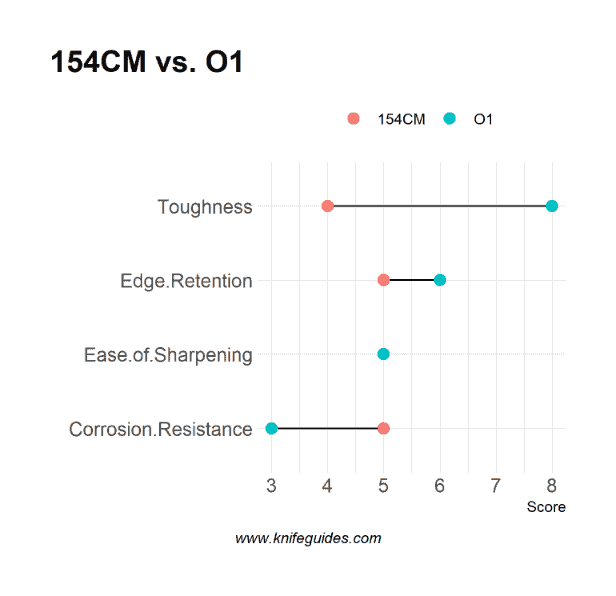

154CM vs. O1

O1 is a tool steel known for its very high toughness. However, it’s poor at corrosion resistance compared to 154 CM.

Top 154 CM Knives

Here are a few top knives made of this steel.

| Image | Title | Price | Buy |

|---|---|---|---|

| CIVIVI Brigand Flipper Pocket Knife | Check Price on Amazon | |

| Kizer Knives Sheepdog XL C01C Knife | Check Price on Amazon | |

| Benchmade Mini Barrage 585 Knife | Check Price on Amazon | |

| Buck Knives 0616BKS OPS BOOT Tactical Knife | Check Price on Amazon | |

| TOPS Knives B.O.B. Fieldcraft B.O.B. Hunter | Check Price on Amazon |

So, is 154CM a Good Knife Steel?

Yes, with its durability, excellent wear resistance, and a good level of toughness and hardness. It is also a mid-range option hence attracting those ready to invest moderately on a knife that they will use heavily.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.