(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

A woodworking router is perhaps among the most valuable as well as essential tools in the arsenal of a woodworker. The best wood router, together with a set of bits, allows carving a variety of intricate designs, including for joints, edges, and grooves. Different types of woodworking routers exist, whose differences you need to comprehend for making an ideal choice that shall fit both your bill and needs. Otherwise, you may end up getting an unsuitable one. This is why reading this guide, along with a few genuine wood router reviews, is essential.

>>If you’re in a hurry click here to find out our favorite Wood Working Routers<<

Routers are masters of cutting grooves with a steady base and an adjustable bit (cut depth) of the chosen size and shape. Such a blend facilitates the endless potential for discarding material in a controlled manner. A wood router can perfectly cut the tails of tenons, mortises, tongue and groove joints, and dovetail joint. There is much more you can do with a router; in fact, a variety of other things. So, you may feel like buying two routers to fulfill your diverse requirements. For that, you need to ask the following questions to yourself for shrinking your list of options for easier and quicker selection.

- What kind of woodwork will I be doing?

- Do you do a lot of work with large diameter bits?

- Will I be performing plunge cutting quite frequently?

- Will I be moving a lot with the router?

- Will your router be table-mounted?

Once you ask these questions, you need to analyze the buying factors we have discussed. Before that, let’s jump into our favorite wood router available on Amazon.

5 Best Wood Routers in 2024

DEWALT DWP611PK

Bosch 1617EVSPK

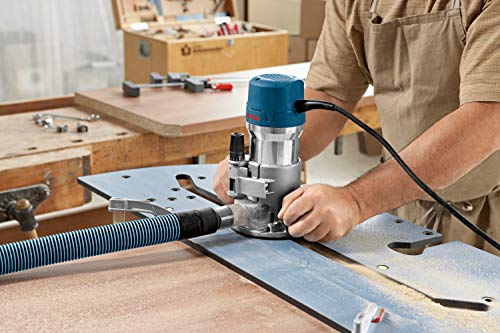

The kit also has an elite quick-clamp mechanism for tool-free motor motion from base to base. The two bases come with big openings for rendering bigger visibility as well as accommodating bigger bits. While the motor remains stable at the time of adjusting the depth, the cord locations, and right or left switch ensure both consistency and choice. No matter which base you choose, the brand’s precision centering design facilitates centering the template guides. Click here to see our article on this router

Check Price and Reviews on Amazon

Black & Decker RP250

This one is an entry-level but long-lasting router for plunge base fans. With 10 amp motor having variable speed ranging from 8,000 to 27,000 RPMs, this 2.25-inch unit comes with all features of a fixed router and other capabilities to perform way beyond. It can create pretty edging, inlays, and cut-outs, as its unique design allows starting work in the middle of the wood piece, and not at the edge. The unit also features a gradual start function for optimum control, safety, and precise output. The SIGHTLINE base ensures convenience, improved visibility, and a simple depth scale for improved accuracy.

Other features include a spindle lock for simple bit changes, 1/4-inch collet, trigger switch, chip shield, three turrets stop for quick repetitive depth cuts, an adjustable parallel edge guide, and metallic casing. Click here to see our article on this router

Check Price and Reviews on AmazonPORTER-CABLE 690LR

Other features of this router include easy bit removal, under-table stop for easy to use, aluminum housing and base, anti-dust switch, micrometer depth adjuster up to 1/128-inch accuracy, and cam-lock level for simple motor release and coarse height adjustments. Consider this unit ideal for a busy professional site or shop. Click here to see our article on this router

Check Price and Reviews on AmazonDEWALT DW618PK

Other features include depth adjustment ring for precise 1/64-inch increments, tool-free steel motor cam lock for quick locking, and dust collector for superior bit visibility. There is no centering tool, however. Click here to see our article on this router

Check Price and Reviews on AmazonWhat to Look for in the Best Wood Router

Factor 1: Types of Wood Working Routers

Selecting the right type is perhaps the fundamental step toward quick distinct wood detailing for any kind of wood projects. You can expect faster and more accurate wood joints than other ways of making joints, a point that several wood router reviews do not forget to mention.

Routers are classified into two ways: according to their size and base. As per the size, woodworking routers are split into the following three types:

- Trim: These are affordable and compact little wonders featuring a motor power of 1 HorsePower (HP) or less and a quarter-inch collet for use with only smaller bits. This means trim routers are designed only for discarding small quantity of wood. They are small and lightweight due to which they are easy to use. Get this type of router if you need to cut a small contour or fine joinery, carve hinge mortises, or soften sharp edges. The grip is good, and size is such that you will not feel intimidating while handling it. It is a handy tool for beginners to sharpen and hone their skills.

- Mid-Sized: These are all-purpose routers that serious hobbyists and professionals tend to bring or prefer initially. With 1.5 to 2.25 HP, these units are capable of rendering different carvings with a variety of bits covering more base than the small ones. Such motors call for two-handed or table-mounted performance, with either a plunge or fixed base. Such routers are quite versatile, as they can do almost every routing task right from big cuts to dovetailing. Look for such a type if you need just one router to do all detailing for you.

- Large: These routers are ideal for a router table, as they are tiresome for handheld operation and are considerably heavy. With almost 3 HP or more motor power, these routers can discard much wood with large bits. Consider such a router if you need it for tasks such as raising panels for the doors of cabinets. The potent power, extra size, and additional weight can handle any tedious or heavy-duty task, but the investment should be made when you are firm to take up such tasks. If you decide to bring one such piece, consider having a variable speed motor so that you can decrease the speed with an increased bit size.

Whether you buy a medium-sized or a large unit, you have a choice to make when it comes to selecting its base. As per the base, the routers are of three types namely,

- Fixed Base: This is exclusively for beginners with a base performing when fixed to a router table. Such a router is best for molding with straight-line accuracy, general profiling, edge cuts, and other tasks, provided the bit is fed into the wood’s edge. Well, the fixed base prevents pushing the bit into the wood. You can position it to different blade depths for cutting by turning the unit off along with the handle close to the base’s bottom for achieving a low gravity center. Such routers are lighter and easier to use than plunge models

- Plunged: Such a router features a spring-loaded base, letting the bit of penetrating the wood. While using for various applications, you simply have to lock the base at a determined depth. Unlocking it allows changing the bit depth at the time of usage. The benefit here is that the cut starts in the mid of the unit instead of at the edge. Such models are more versatile but maybe a bit tougher to use than the fixed base ones. They are also relative costlier. For all tasks, a plunge router can perform anything that a fixed base model can do, but the handles and motor are higher for enabling the plunging motion. Due to the elevated center of gravity, you may even feel somewhat unstable, particularly while milling small stock.

- Interchangeable: These lighter models, available mostly as kits, have the best of both plunge and fixed base designs. You can switch from one type to another by easily removing the motor from one base and putting it to another. With such a mechanism, you can easily expand your router without investing in the second one. It is also possible to attach one to the router table and leave the other for portability. In case you keep changing the base too frequently, you may find that having two different routers is yet the most efficient option rather than halting to change the base so often.

Special Note on Rotary Tools

There is even a rotary tool that provides routing facilities to those who do not require the capacity and power of a standard router. Weighing between one and four pounds, this little unit is ideal for fine detail and small routing tasks to be done by hobbyists and crafters having light but diverse requirements. With the motor power ranging from 1 to 5.5 amps, a rotary tool is very compact and versatile enough to perform various applications in addition to those of routers.

Special Note on Computer Numerical Control (CNC) Routers

If you are a tech fan, you may love to have a CNC router, which are computerized experts in making objects out of wood. It works based on the Cartesian system employing the X, Y, and Z coordinates for ensuring 3-dimensional (3D) motion control.

A CNC woodworking router uses a computer application along with a CNC controller mechanism for accomplishing better precision and control than a human operator. You can design a few parts in the computer through a router-compatible CAD application such as Bobcad and Mastercam, and then shape it using a cutter or a router.

A CNC router is perfect for art, product development, and engineering prototyping work. It is analogous to a metal CNC mill, but spins faster, is bigger, and has more HP ranging from 5 to 15.

Suggestion on Buying One or More Routers

Usually, people prefer buying two routers, one small and another large. This is both for the starters and experienced. Woodworkers are having 15+ routers, each with a fixed setting that they do not wish to modify even later, which is handy. In case you can get only one, select the one that is versatile enough to do most tasks of yours. Consider a medium-sized or a large router with a router table.

For those who are assembling a collection, it is suggested to get a large router for gaining the benefit of versatility. Later, it is wise to add a small router for detailing work.

Factor 2: Router Bits

Different types of router bits are available for achieving a variety of designs and grooves. Most of these come with different shank sizes to fit as per the router’s size.

- Beading: For putting a convex edge on the wood and is a bit below the level of wood sides

- Round Over (Similar to Beading): For having a rounded edge without recessed edges, along the piece

- Straight: For cutting a groove with varying diameters

- Dado (Famous): For having a box groove throughout the target piece

- Rabbeting: For having a right-angled cut along the edge of the wood

- Chamfer: For cutting a straight edge at an angle besides the wooden side or a beveled edge for decorative reasons on a corner

- Cove: For cutting a concave quarter circle (inward) along the wooden edge

- Roman Ogee: For having a distinct s shape along the edge

- Dovetail: For having the groove with a wider bottom throughout the wood

- V Groove: For having a groove in a V shape across the wood

- Round Nose: For having a half-circle groove

Factor 3: Bit Materials

Router bits are generally made up of one of the following materials.

- High-Speed Steel: This material is ideal for working with softer materials. While it is most affordable, it does not sustain its edge sharpness as long as other materials. Consider this material only for using a router occasionally.

- Carbide Tipped: Such a bit is designed using a much stronger material than the high-speed steel. Carbide tips tend to sustain their edge longer than the steel bits. They can easily cut harder metal as well as wood pieces. Such bits are ideal for professional woodworkers who need to use a router daily.

- Solid Carbide: These bits are the most durable as well as strongest ones due to which they are ideal for the hardest materials. The edges sustain themselves well for a longer period without creating any issue. However, these bits are costliest but are worthy of their longevity.

Factor 4: Motor Power/HP and Speed

Different models come with different speeds and horsepower. The most common HP options range from 1.5 to 3.5, but your choice depends on the kind of tasks you will be doing. A reasonably powered router with 1.25 to 2 HP can handle most softwoods along with a few hardwoods as well as light metals. Such a router is ideal for occasional use, whereas a higher HP is required for regular heavy use.

For high load or metalwork, consider a model that allows adjusting Revolutions Per Minute or R-P-M regardless of the load level. A few woodworking routers come with RPMs ranging from 9,000 to 30,000 for having the variable speed control.

The majority of mid- and full-size routers come with variable speed control, which is handy for using a single router for all bit sizes. Small bits give clean cuts at mid to high level of speed, while big bits need a lower level for a safe cut. If there is variable speed, you simply need to twist and use the desired speed level.

For choosing both the right speed and power, you need to know the tasks for which you will be using a router.

Factor 5: Wood Router Table

A router table facilitates attaching a router to the table with an upward bit. Usually, a router is mounted beneath the table with the bit fixed up via the table’s top. Once the router is at work, the wood piece tends to move across the tabletop as well as atop the blade or bit. With a router table, you can complete several routing tasks more conveniently as well as consistently than by hand.

You can find tabletop versions that you can put on a workbench, or free-standing models of tables. You can even find a portable table or get a table of your choice built.

Factor 6: Router Design

A woodworking router features a case for holding and insulating a motor for spinning the blade or bit, handles for guiding across the piece to be cut, and a collet or metal securing sleeve for retaining the bit securely in place at the router’s base. The collet size varies from 6 mm to 0.5 inches. However, the best wood router will also come with measurement scales for setting the precise depth of the bit without taking the measurement manually. In short, look for a comfortable design that ensures precision and effortless operation.

Do also look for ergonomic handles, which ensure comfort and proper grip while at work, particularly for lots of time-consuming jobs that need to be performed subsequently. If there are two handles, ensure that they are layered with a rubberized material; as such, it can add much more comfort.

Factor 7: Collet Size and Maintenance

A collet is a sleeve holding your router bit along with the help of shaft attached to the motor and the collet nut. With the size ranging from quarter to half inches, collets are usually of four styles, namely, split shaft with sleeve adapters, split shaft, tapered shaft with multiple slits, and tapered shaft with a single slit.

Any tool with contact from metal to metal or with the possibility to contact dust and sap is likely to wear over time. This certainly calls for good and timely maintenance. This applies to collet that becomes worn out or scratched due to which proper hold is not given to the bit, ending up in wobbling and vibration. Therefore, you need to take proper care of the collet. For that, you should avoid tightening the collet without the bit in place. Further, dust and sap can clog the collet and its nut as well as limit the shaft’s recess.

To fix this, consider buying a model with a vacuum port or a dust port that can save much of your cleaning efforts and avoid the accumulation of dust or sap. Such a port even keeps your work area clean as well as keeps breathing-related issues away. Most modern routers come with this newly added feature.

Factor 8: Wood Router Fences

The fences offer a guide against which the wood is pushed. This does not allow shifting of the wood piece and facilitates precise straight line cut.

Factor 9: Electronic Feedback Circuitry

Routers with such feedback are smart enough to retain a consistent speed so that there is no bogging down in case the load increases. The circuitry keeps an eye on the motor load and adjusts the output of torque accordingly. As a result, the motor does not stop during a heavy cut and that the power output remains the same. With the router keeping pace, you can now focus on cutting performance.

Factor 10: Other Vital Features

Go through wood router reviews, and you will find customers recommending the below-listed features. Read on to find out ‘why.’

- Soft Start: This feature makes the unit blast up to full speed in one go. A moment of pause is felt after starting it up, but the unit quietly and softly accelerates to the set speed. This feature is standard in those units that have electronic feedback.

- Microfine Depth Adjustment: Look for this feature if you need very minute and accurate depth-of-cut adjustments for more versatility as well as accuracy.

- Spindle Lock: Many routers need two wrenches for changing the bit. While the one sustains the motor shaft, the other either tightens or loosens the collet. When you have a spindle lock, a spring-loaded pin or a locked collar sustains the shaft in place. This means, now only a single wrench is required. Such a change is handy for plunge routers, which do not allow removing the motor for better access to the bit.

- Adjustment over the Table: It is not uncommon for a router to live under a router table in a hanging mode. To ensure more precise and comfortable table routing, you need to look for two new features. First, choose a model that allows adjusting the cutting of height from atop the table through a knob or handle. This eliminates the need to bend down for twisting the depth setting. Second, the model should extend the collet upward for changing the bits without lifting the unit out. You will find both these features in units of the ATA brand.

- Jigs and Clamps: Jigs are essential for holding your piece securely for cutting dovetail joints, box joiners, dada joints, and hinge recesses. Similarly, clamps are required for clamping the piece such that there is no slipping at all. A clamp also holds the jig such that you are ensured of stability.

- Speed Options: Well, these are in the form of controls or on/off switches. A few routers may have a variable speed trigger. In case you have a task wherein both hands will be used, consider a model with a footswitch for turning the unit on and off. This ensures comfort and convenience while doing such tasks.

- Templates: Consider these accessories if you wish to do all types of intricate designs effortlessly, especially if you are a beginner. You only need to affix a template and follow it with the router. You need to purchase templates separately.

Conclusion

Through this guide and inside wood router reviews, buying the best wood router may seem easier than using it, particularly for the beginners. You only need to select the right model at the right price. There is no need to spend much money on bringing home the best quality. Just keep educating yourself, update yourself about your needs and budget, and are about the get the best model in no time. After all, the best quality is the one that gives you the desired result consistently as well as for a long time, right? This is best ensured through informative and analytical knowledge!

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.