(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

If you have been looking for European knives for tactical, bushcrafting, or other outdoor applications, chances are high for you to spot N690 steel as the blade material. Many European knives will have it, as this steel is quite popular across the continent.

What is N690Co Steel?

The N690Co steel is cobalt-rich stainless steel from Bohler, a company in Austria whose steel sheets are always used for making upscale and high-end knives. This is why you get to see it in several European knives.

The origin of this alloy is N690 steel. As cobalt was added to this steel, some knife makers called it N690Co. It is high-carbon stainless steel, to which cobalt is added for fostering structural consistency. Technically, this is a fine-grained steel form whose blades sustain their sharpness despite being subjected to prolonged usage spells.

N690 and N690Co are used these days interchangeably for the same steel.

This special high-carbon and cobalt steel can handle heavy stress. Hence the steel is used across the globe for making camping, bushcraft, and tactical knives.

Bohler makes this stainless steel so that the manufacturers of knives find it easy to use. The credit goes to the trivial differences in its mechanical properties. In simple words, this means spending no time determining or spotting the direction of the grain before cutting the steel. As a knife user, this translates to more affordability due to less production effort.

N690 Composition

N690Co steel has high chromium, carbon, and molybdenum content, thus balancing toughness and hardness. Steel is considered stainless if its chromium content is above 10.5%. In this steel, the chromium content is over 17%; hence it is stainless steel.

Its chemical composition is quite close to 440C with analogous amounts of chromium, carbon, and molybdenum. Apart from these three, it also has cobalt and vanadium to enhance the alloy properties. Following are the various elements of which this steel is made up:

- 17.3% chromium for improved edge retention, tensile strength, and wear as well as corrosion resistance

- 1.65% cobalt for enhancing the individual impact of other elements

- 1.07% carbon for better hardness as well as resistance to wear and corrosion

- 1.1% molybdenum for improved strength as well as manufacturing ability (machinability)

- 0.4% manganese for more hardness

- 0.4% silicon for better strength

- 0.1% vanadium for better hardness as well as wear resistance

Hardness

Due to the mix of cobalt and high carbon, the N690 stainless steel is very hard. However, the knife makers make sure it does not get too hard during heat treatment. As with the presence of cobalt, a risk of being brittle is always there.

Typically, this steel gains a rating of approximately 60 HRC, mostly the hardness range is between 59 and 61. That said, you get a hard edge for tough outdoor applications with a reduced risk of chipping.

Properties

The chemical composition of this steel dictates its properties. Following are its most significant properties that you can expect from an N690Co knife:

- Great Cutting Ability: The hardness level of this steel is ideal for cutting stronger and tougher things than the plastic and paper ones. You can easily cut wood, rope, and other things seen outdoors with it.

- Superb Edge Retention: The edge does not dull fast and is better than most steels. The credit goes to the inclusion of cobalt that delivers a consistent fine edge.

- Superb Corrosion Resistance: It can keep rust and corrosion at bay even in too wet conditions. You can expect resistance to damage from exposure to harsh elements such as salt, moisture, and humidity. This is attributed to the inclusion of much chromium and manganese, molybdenum, and vanadium.

- Great Wear Resistance: The inclusion of cobalt, a heat-resistant and super-hard metal, makes this steel more resistant to wear than many other steel knives. Even the premium steel edges tend to wear with time, as you use them as well as resharpen them a lot. However, an N690Co edge can last for several years without wear. This is another reason it is preferable to make knives for outdoor activities.

- Easy to Sharpen: Although you are ensured of a good cutting edge for a long time, the edge of this steel will dull at some point in time. Resharpening it is an easy job.

- Toughness: It is tough to find a steel type that delivers a good level of hardness and toughness. Well, this is one such steel. Although N690Co may not provide a superior level of toughness, its toughness level is decent.

Comparison with Other Knife Steel Options

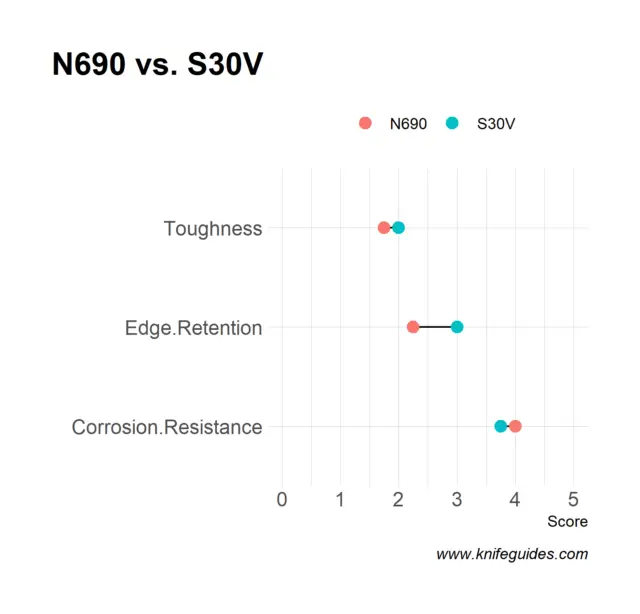

N690 vs. S30V

Both of them score almost the same in terms of corrosion resistance and toughness. However, S30V retains an edge for a longer period. It is also costlier. On the other hand, an N690Co edge is easier to sharpen.

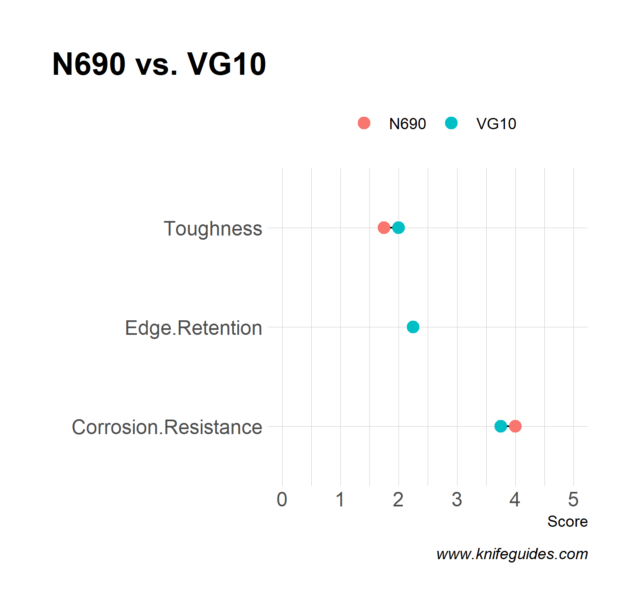

N690 vs. VG10

Both are medium-range steels and rank almost the same when it comes to corrosion resistance, toughness, and edge retention.

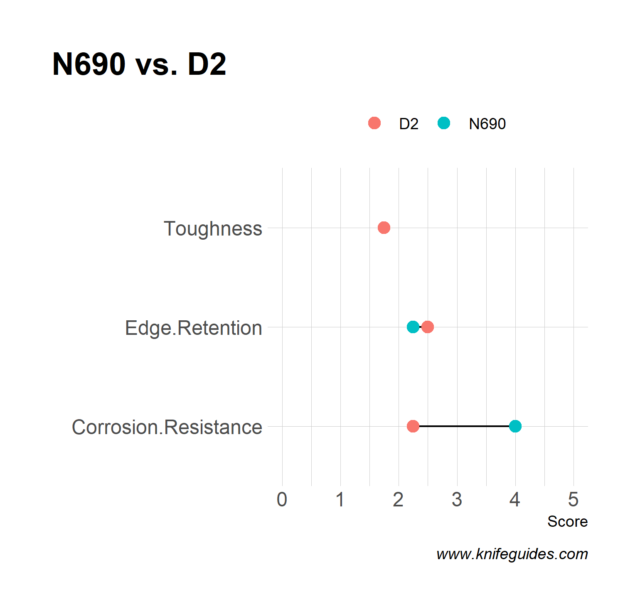

N690 vs. D2

D2 is another medium-range tool steel. So, it is quite harder than most other steel variants and retains its edge sharp for a long period. However, it falls behind the Bohler steel in corrosion resistance. It does have chromium but is not as sufficient as required to be a type of stainless steel. On the other hand, it is more difficult to resharpen a D2 edge.

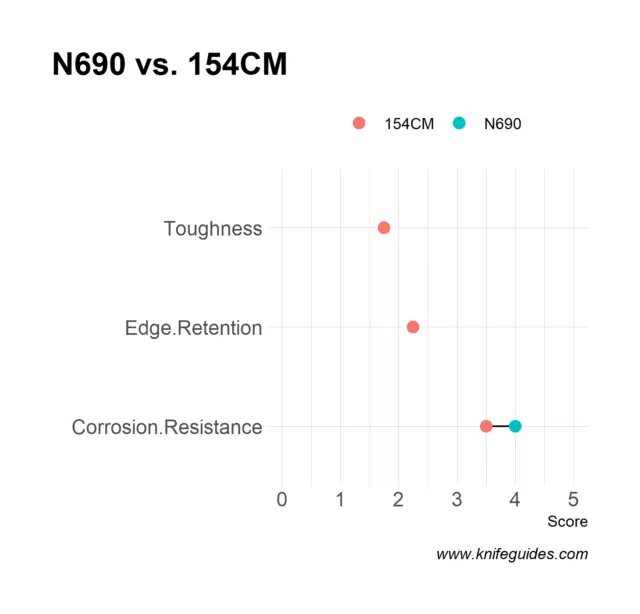

N690 vs. 154CM

You can expect decent edge retention as well as corrosion resistance from 154CM. However, N690Co is a better option for rust resistance. In everything else, both score the same.

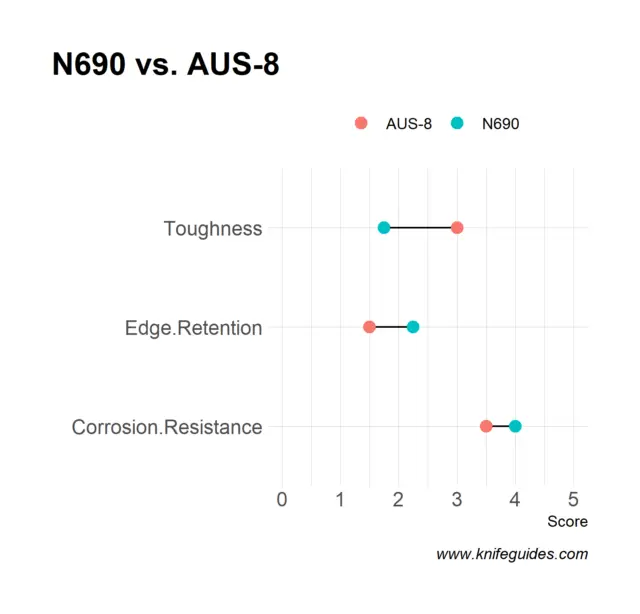

N690 vs. AUS 8

AUS 8 is a budget steel option and is tagged as a decent all-around performer. It has been in the world of steel for quite some time. While an AUS 8 edge is easier to sharpen and its more affordable knife, N690Co is better at maintaining a sharp edge and keeping corrosion at bay.

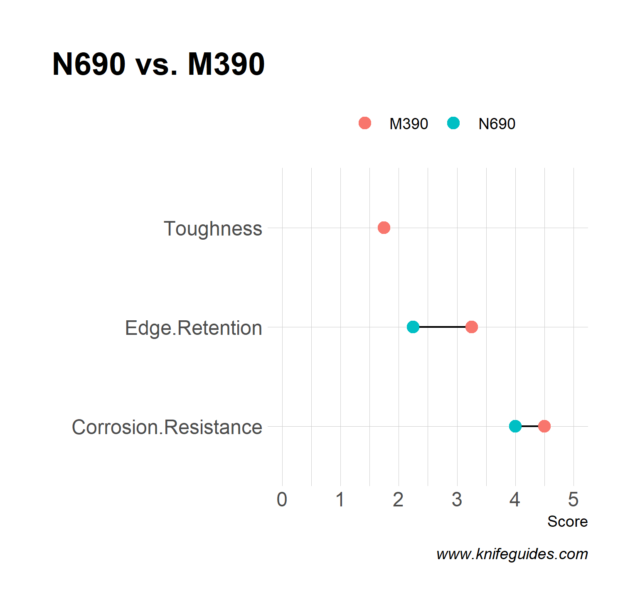

N690 vs. M390

The latter steel is known for its better edge retention and rust resistance abilities. However, it is more difficult to resharpen its edge than N690Co. Nevertheless, the level of toughness remains the same for both.

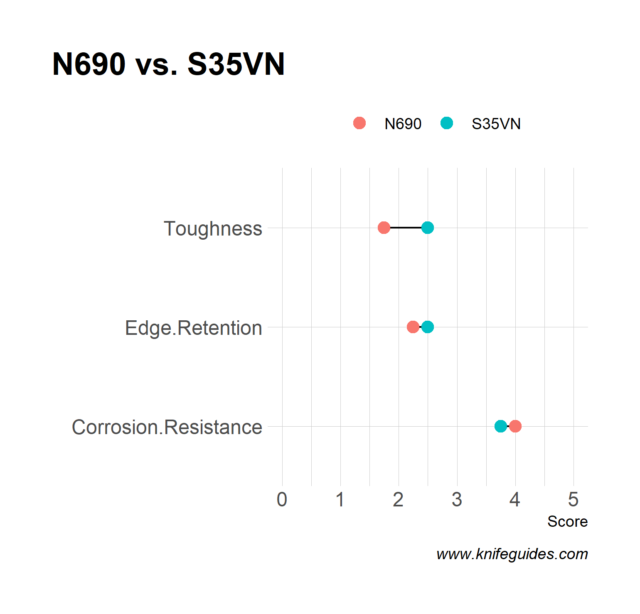

N690 vs. S35VN

Crucible’s S35VN is a high-end steel option. It beats N690 in toughness and edge retention but almost performs at the same level of corrosion resistance as the Bohler steel.

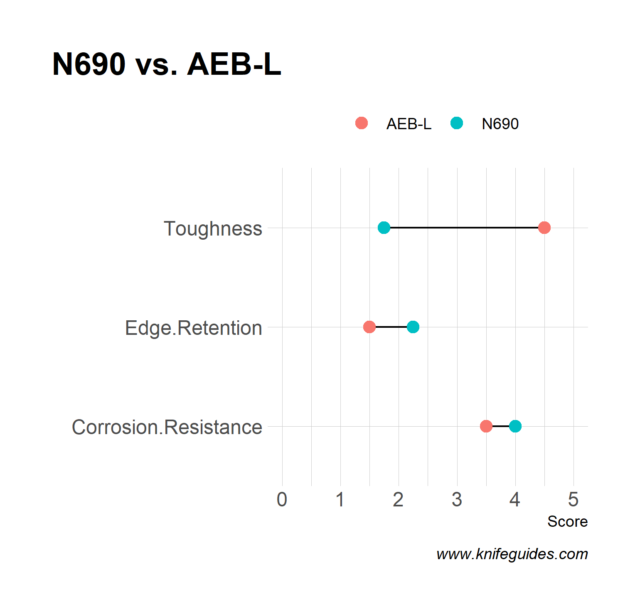

N690 vs. AEB-L

Uddeholm AEB-L is less hard, performing worse in edge retention than the Bohler steel. However, AEB-L excels in toughness and ease of sharpness, whereas the Bohler steel slightly edges it past corrosion resistance.

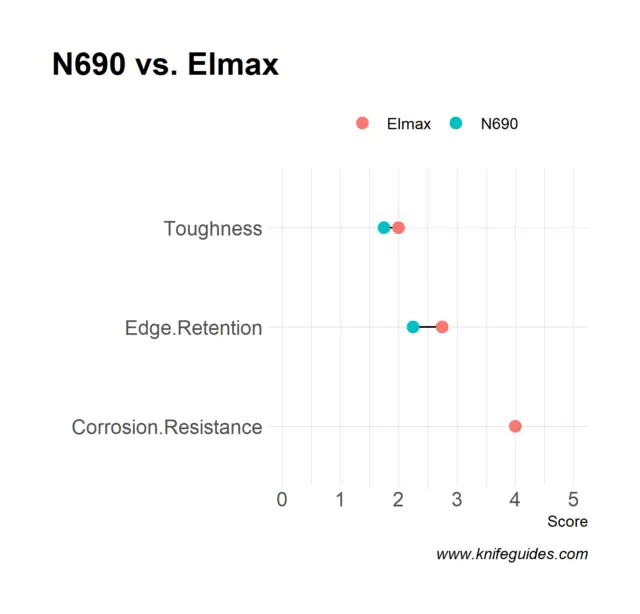

N690 vs. Elmax

Both steel options perform almost the same in all aspects. However, Elmax wins over the Bohler steel in toughness and edge retention in a close race.

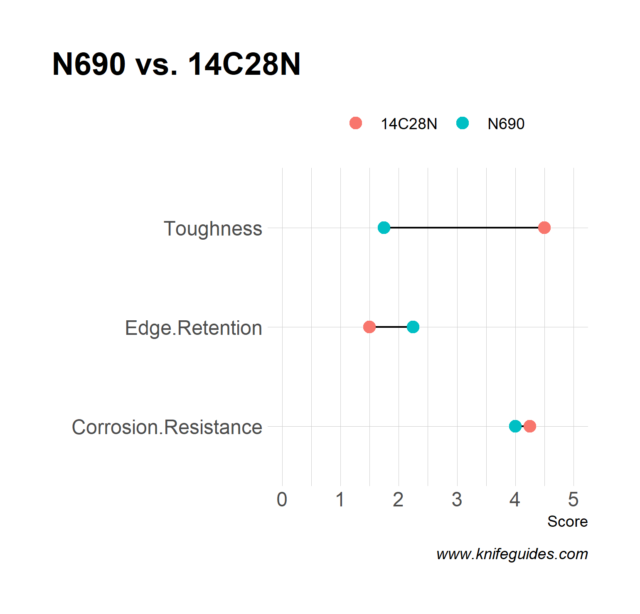

N690 vs. 14C28N

N690 fares better to the Sandvik’s steel in edge retention as it is harder. But in toughness, ease of sharpness, and corrosion resistance, 14C28N wins.

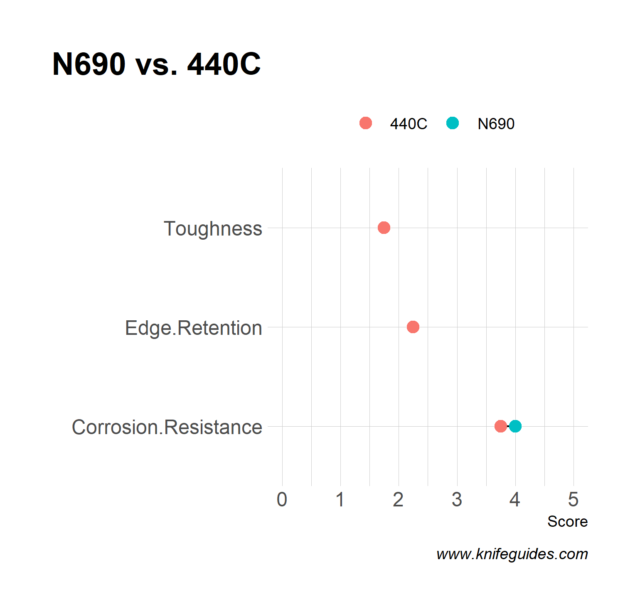

N690 vs. 440C

Both the steels are almost the same performance except for resisting corrosion. The Bohler steel is slightly better than the 440C.

So, is N690 Stainless Steel Good for Your Knives?

Yes, if you are looking for a knife with excellent resistance to corrosion and wear, great edge retention, good toughness, and superb corrosion resistance for working in the bush or wild. It is ideal for working in wet or tough environments, as it is easy to sharpen anywhere. But you will end up paying more than usual, as it is a high-end steel option.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.