(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Evaluating the blade steel’s properties is wise before buying a knife. For example, do you not want to buy a knife with poor corrosion resistance in a humid environment? CPM 3V is one of the high-end steels available today. So, what makes it great? Let’s find out in this post.

What is CPM 3V Steel?

Popular as 3V, CPM 3V refers to a kind of tool steel with a high carbon amount. It is made by the American brand called Crucible using its proprietary Crucible Powder Metallurgy (CPM) process. This technological process leads to even dissemination of carbides, which results in stronger options than those formulated using the standard processes.

Crucible specifically made this carbon steel to ensure maximum resistance to chipping. It was originally made for applications wherein other tool steels performed poorly.

This tool steel belongs to the same category as other steels such as D2 and O1. However, it’s a wear-resistant, high-toughness tool steel. This makes it ideal for various applications such as shearing blades, dies, punches, stamping tools, blanking tools, scrap choppers, slitters, and other industrial instruments requiring crazy amounts of toughness.

Its toughness level also makes it a popular build material for knives, especially fixed blades, large knives, and swords. It is commonly used to camp, and bushcraft knives are usually meant for tough tasks.

Chemical Composition

CPM 3V has a low percentage of chromium, hence cannot be categorized as stainless steel. Following are the elements that make up this steel.”

- 0.8% Carbon: For more hardness, tensile strength, and good ability to keep wear and corrosion at bay

- 7.5% Chromium: For more edge retention, tensile strength, toughness, hardness, and resistance to corrosion and wear

- 2.75% Vanadium: For more strength, toughness, and hardenability

- 1.3% Molybdenum: For better hardenability, toughness, strength, and hardness

- 0.9% Silicon: For strength and resistance to corrosion

- 0.4% Manganese: For enhanced forging, tensile strength, wear resistance, and hardenability

- 0.4% Tungsten: For better hardenability, toughness, and strength

- 0.03% Sulfur: For better machinability and impact toughness

- 0.03% Phosphorus: for improved hardness, machinability, and strength

Hardness

Crucible CPM 3V has a rating between 58 HRC and 60 HRC on the Rockwell scale. This aligns with what the experts suggest as the perfect knife steel hardness (above the 50s and below 60s). This range of hardness is high.

It is, however, possible to treat the steel to increase the hardness rating to 62-64 HRC. However, this would result in reduced performance in terms of impact toughness.

Properties

- Commendable Toughness: When it comes to steels, toughness is the power to keep away breakage or chipping at the time of use. This encompasses instant, sudden, or repeated impacts during batoning, chopping, or industrial tasks. Well, this power of CPM 3V is commendable. The credit goes to its more homogenous microstructure than other steels such as A2 and D2. You can easily find that the toughness of this knife is comparable to shock-resistant steels. After all, this steel was made for applications requiring great chip resistance and superior toughness.

- Excellent Wear and Abrasion Resistance: This is where this high-carbon tool steel wins the crown. Including more carbon content and adequate vanadium content is responsible for this great property. In addition, the presence of harder vanadium carbides makes them more resistant to wear than steels having no or fewer vanadium carbides.

- Excellent Edge Retention: As the maximum hardness rating of this steel can go up to 60 HRC, it is bound to provide excellent edge retention. With a superior ability to retain sharpness, it wins over tool steels such as D2 and A2. Nevertheless, indeed, it may not retain the sharpness and high-end options such as S35VN and S30V.

- Decent Corrosion Resistance: This steel is known for its fair ability to keep corrosion at bay. This is commendable considering that it is tool steel, not stainless steel. Nowadays, CPM 3V steel knives come with tough coatings to boost resistance power to corrosion.

- Ease of Sharpening: As this steel can get hard if the rating reaches 60 HRC, it needs strong and harder abrasives to restore its dull edge. Considerable effort is also required to get a sharp edge.

Comparison With Other Knife Steel Options

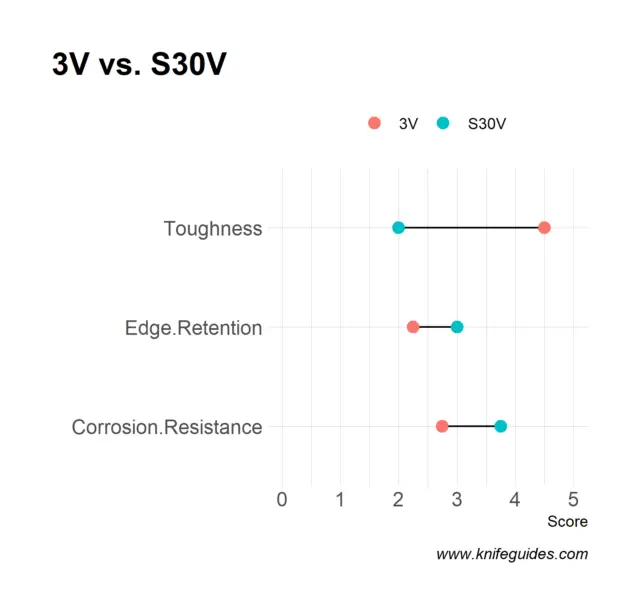

CPM 3V vs. S30V

S30V is superior to CPM 3V in terms of corrosion resistance and edge retention but loses when it comes to toughness.

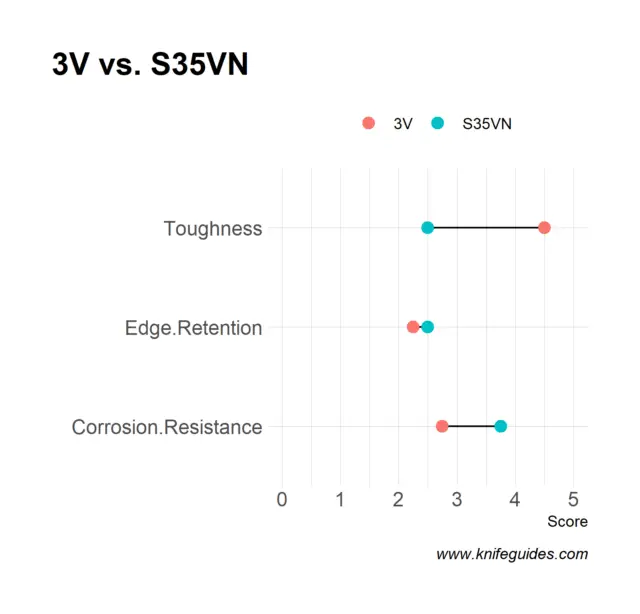

CPM 3V vs. S35VN

Regarded as the big brother of S30V, S35VN is more corrosion resistant than CPM 3V. However, the latter is tougher as well as more affordable. Nevertheless, both offer similar performance when it comes to ease of sharpening.

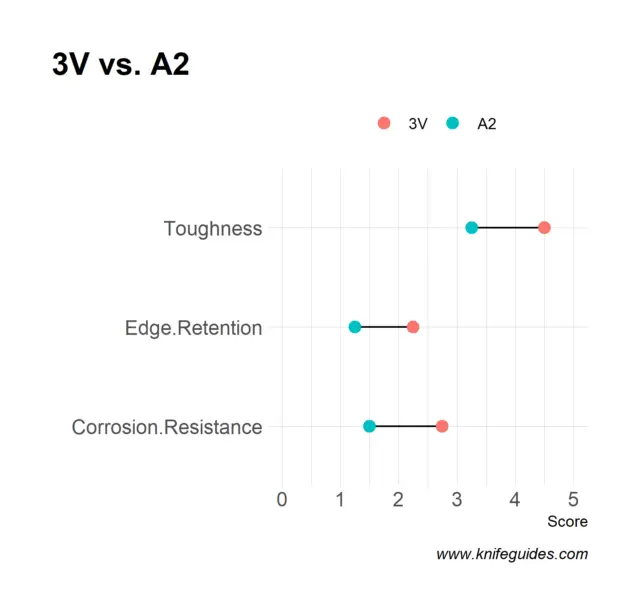

CPM 3V vs. A2

CPM 3V is tougher than A2, famous tool steel known for high toughness. 3V is also better at edge retention and corrosion resistance as well.

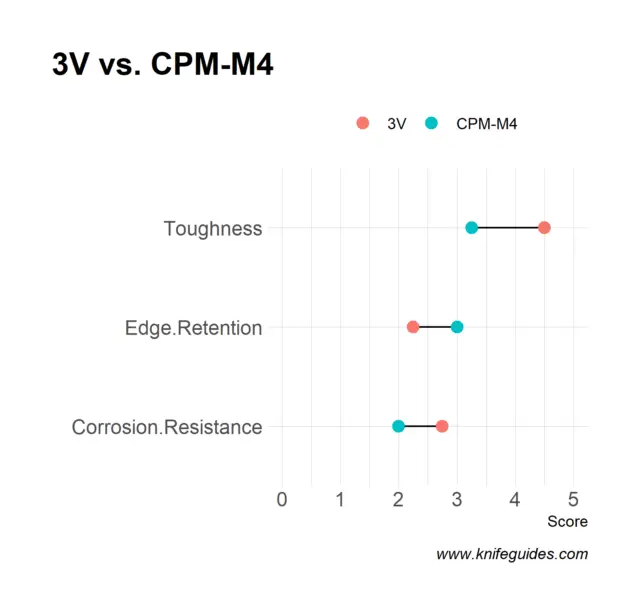

CPM 3V vs. CPM M4

Both steels come from Crucible. M4 wins over 3V with a higher ability to retain a sharp edge. Otherwise, 3V wins in terms of ease of sharpening, corrosion resistance, and toughness.

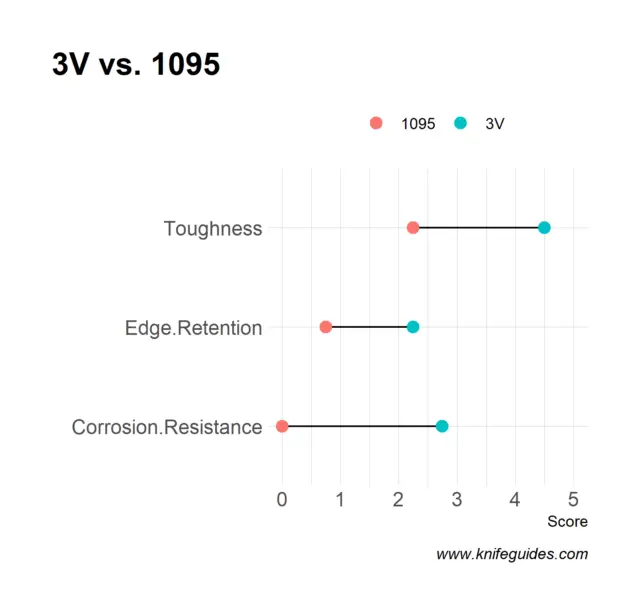

CPM 3V vs. 1095

Regarded as one of the famous high carbon steels in the world of knives, 1095 is easier to sharpen than CPM 3V. On the other hand, CPM 3V offers better edge retention, corrosion resistance, and toughness.

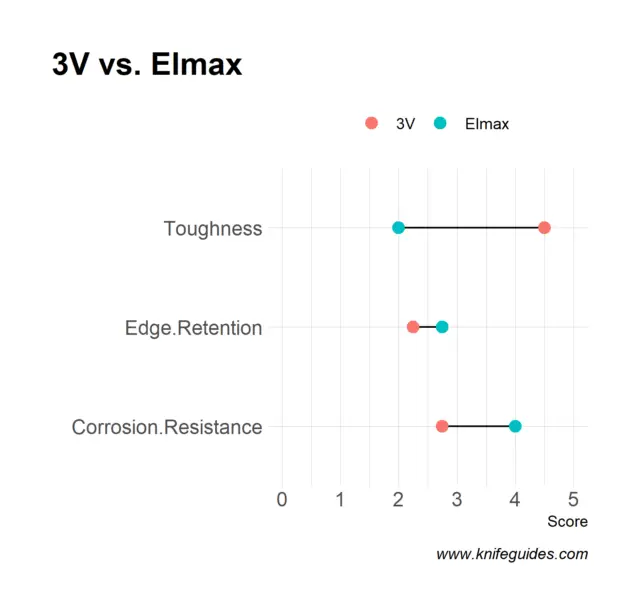

CPM 3V vs. Elmax

Elmax offers higher edge retention. Although Elmax provides decent toughness, 3V steel is even tougher. Elmax is better at corrosion resistance as well.

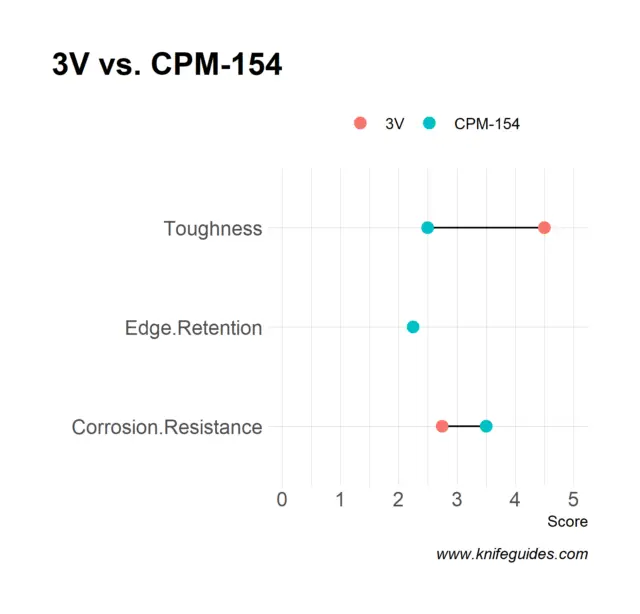

CPM 3V Steel vs. CPM 154

CPM 154 offers better resistance to corrosion 3, as it has higher chromium content. However, 3V is better when it comes to chip resistance under impact.

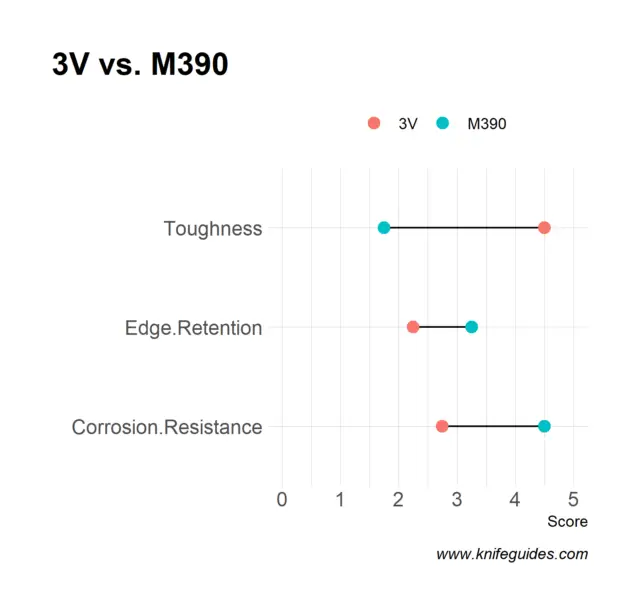

CPM 3V vs. M390

Bohler M390 is a premium steel. It has superior edge retention and corrosion resistance to the Crucible steel.

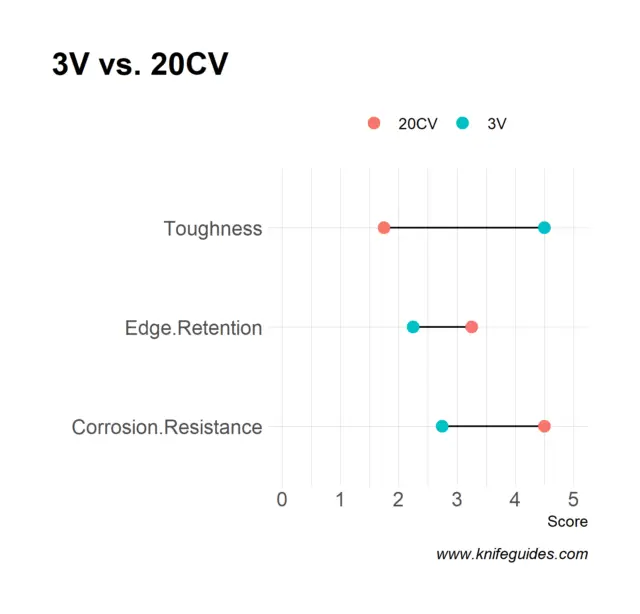

CPM 3V vs. 20CV

In terms of hardness, edge retention, and corrosion resistance, 20CV is better.

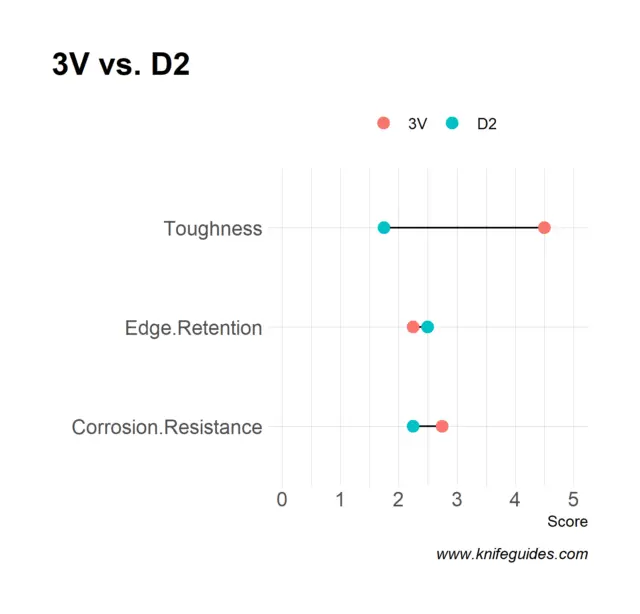

CPM 3V vs. D2

D2 is slightly better at edge retention. On every other aspect, the Crucible steel wins.

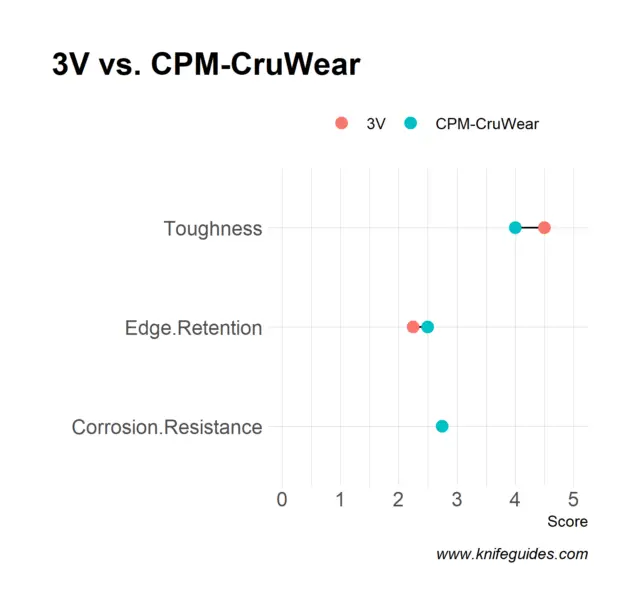

3V vs. CruWear

3V and Cruwear have very similar performances in every aspect.

So, is CPM 3V Steel Good?

Yes, if corrosion resistance is not a priority for you. The CPM 3V steel is admired for its excellent toughness, due to which its knives will not chip or break quickly or easily. Further, these knives can retain their sharp edge for a long.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.