(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

If you have been looking for premium Spyderco knives, you are likely to come across a CPM S110V steel. Let’s explore its chemical composition, characteristics, and performance compared against its peers.

What is CPM S110V Steel?

Commonly known as S110V, CPM S110V is a premium-tier tool steel alloy belonging to the category of martensitic stainless steels. Made by the Crucible brand in the United States, this steel is formulated using the patented Crucible Particle Metallurgy (CPM).

This powder metallurgy tool steel is unique, as it contains high carbon as well as vanadium and is known for extremely high wear resistance. Just as other high wear resistance steels such as M390 and S90V, it was initially made for use in plastic injection projects requiring a blend of high resistance to wear and corrosion.

Today, this steel is widely used in making industrial knives, food tools, slitters, circular cutters, and screw elements. However, it is not very popular amongst knife makers, as it is somewhat hard to work with and needs abrasives of good quality.

Chemical Composition

CPM S110V contains high amounts of carbon, chromium, molybdenum, and vanadium. Unlike many other steels, it has niobium. Due to a high chromium level, it is stainless. Below are the components that make up this premium steel alloy:

- 2.8% Carbon: For increased hardness and better ability to keep wear as well as corrosion away

- 15.25% Chromium: For increased tensile strength, resistance to corrosion and wear, and edge retention

- 9% Vanadium: For increased wear resistance as well as hardenability

- 3% Niobium: For increased resistance to wear as well as corrosion and hardness

- 2.25% Molybdenum: For increased strength as well as machinability and sustained hardness at higher temperatures

- 2.5% Cobalt: For the increased impact of all the aforementioned components

Steel Hardness

S110V has a minimum rating of 64 HRC on the Rockwell scale of hardness. Depending on the heat treatment given by the manufacturer, this level can even reach near 66.5 HRC. This range of hardness is truly high. Thus, this steel is extremely hard.

The credit for this goes to the high amounts of carbon, molybdenum, vanadium, and niobium. The inclusion of niobium leads to the formation of minute but super-hard carbides. These niobium carbides are harder than vanadium carbides and are generated in substantial amounts.

Properties

- Good Toughness: With the hardness level reaching above 64 HRC, it would be obvious to expect this steel to be less tough. The more the hardness level, the less is its toughness level. However, this steel has a good level of toughness that is not commonly expected at its specified hardness level. You can expect a good balance of hardness and toughness from CPM S110V knives. However, this steel is neither the toughest one nor its toughness level is the best.

- Excellent Wear Resistance: This is a no-brainer, as this steel was made for use in applications demanding high resistance to wear. The CPM S110V knives can easily keep wear away due to the distinct composition of chromium, vanadium, and niobium. They will just not get easily damaged from wear, abrasives, or normal usage.

- Exceptional Edge Retention: This is another cool property of this steel. It excels at retaining a sharp edge for a significantly longer period than most steels out there. The credit goes to the higher hardness range to ensure such edge stability. Another reason is an incredibly high level of vanadium that further contributes to a long-lasting edge.

- Good Corrosion Resistance: As CPM S110V is stainless due to 15% chromium, it offers good resistance to corrosion and rust. However, it is not 100% resistant to corrosion and rust and requires additional care to keep both away. With 1% saltwater, this steel exhibits good power to resist corrosion. The secret lies in the vanadium and niobium carbides both of which are hard and contribute to wear resistance. The key to a good blend of wear and corrosion resistance is to balance both these elements. The high chromium level affects vanadium carbide content, and high vanadium contributes to the formation of chromium carbides, reducing toughness and corrosion. As some chromium exists in vanadium carbides, the power to resist corrosion reduces further. Nevertheless, niobium carbides are stronger than those of vanadium, signifying that they are formed despite a high chromium level. Moreover, niobium carbides have a little amount of chromium. These two factors indicate that using niobium rather than vanadium can result in high wear resistance while having a high level of corrosion resistance. This is due to little interaction between niobium and chromium, leaving the latter to add to corrosion resistance.

- Ease of Sharpening: This is where CPM S110V knives lack. It is difficult to sharpen an edge made using this steel because of its high hardness level. Some users have said that it is the most difficult material to sharpen as it does not get sharp even if you use a diamond stone, and you may need to depend upon a professional service. Once you get a good cutting edge, it will last a long time before it demands re-sharpening.

Comparison With Other Knife Steel Options

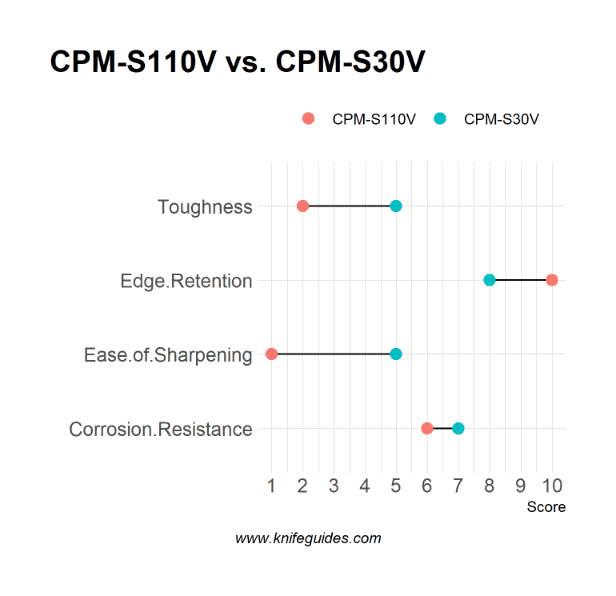

CPM S110V vs S30V

CPM S110V wins over S30V in terms of wear resistance and edge retention. On the other hand, S30V is easier to sharpen and resists corrosion slightly better.

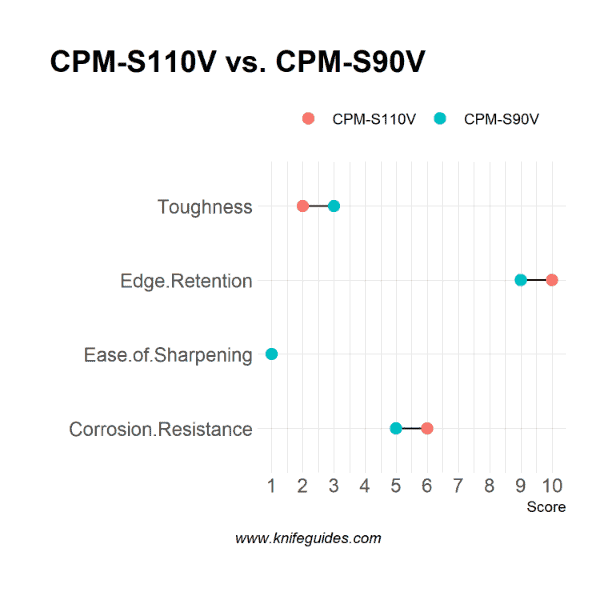

CPM S110V vs S90V

S110V is considered an improved version of S90V. However, S90V is tougher due to less carbide content. However, S110V is slightly better at resisting corrosion and edge retention.

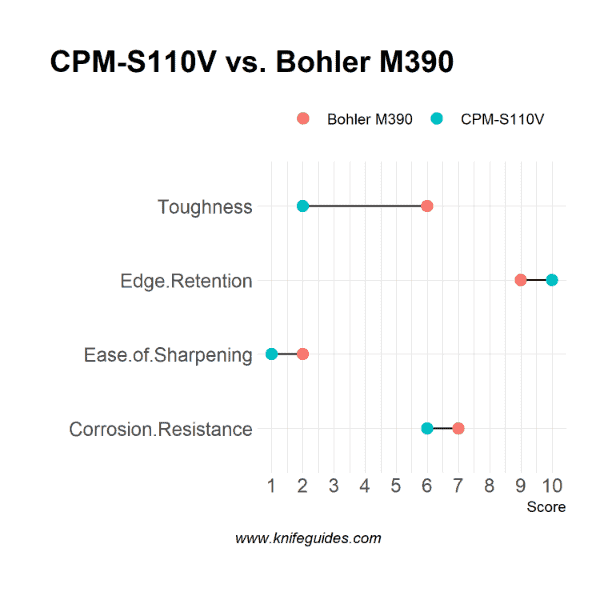

CPM S110V vs M390

M390 is tougher than S110V. However, it is less resistant to wear. This is because of more chromium carbides that are softer than the vanadium ones, in M390. Both steels exhibit similar performance when it comes to edge retention, corrosion resistance, and ease of sharpening.

Top CPM-S110V Knives on Amazon

| Image | Title | Price | Buy |

|---|---|---|---|

| Spyderco Para 3 | Check Price on Amazon | |

| Spyderco Native 5 | Check Price on Amazon | |

| New TwoSun Knives Tepe | Check Price on Amazon | |

| Spyderco UK Penknife | Check Price on Amazon |

So, is CPM S110V a Good Knife Steel?

CPM S110V is a premium steel with an exceptional edge retention capability and is known for its great wear resisatnce. However, just keep in mind that this American premium steel is costly and usually found in knives that cost $100 and above.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.