(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Do you love American steels in your knives? If yes, you must have come across Carpenter CTS XHP alloy. Like any other American steel, this steel is also known for its all-around performance. As a result, it is used in making many upscale knives. Let’s find out about its composition and properties through this CTS XHP review.

What is CTS XHP Steel?

CTS XHP is a type of stainless steel featuring a high amount of carbon and chromium, which is a new type introduced. It is an air-hardening, anti-corrosion alloy produced by Carpenter, a U.S.-based brand.

As the name indicates, this steel belongs to the brand’s CTS series. It is created by powder metallurgy, which is known for delivering fantastic steel performance.

The Carpenter CTS XHP alloy is considered a 440C stainless type in terms of high hardness and a D2 tool steel type in terms of corrosion resistance. This is because its chemical composition is similar to D2 and 440C.

In other words, Carpenter introduced this steel alloy by including the high level of hardness of D2 and the high power of corrosion resistance of 440C.

It is as hard as D2 but has more power to resist corrosion than the D2 semi-stainless steel. A few experts tag it as similar to 440C steel but with a greater hardness rating.

It is widely used for making upscale cutlery, high-end knives, and expensive surgery tools. In addition, popular knife brands such as Cold Steel and Spyderco use it for offering a few high-end knives. This itself proves how reliable this steel is for knife blades.

Chemical Composition

Due to high carbon and chromium content, CTS XHP is a type of high-end stainless steel. Following are the constituents of this steel alloy:

- 1.6% Carbon: For more hardness and better ability to keep wear or corrosion away

- 16% Chromium: For excellent tensile strength as well as the ability to retain an edge and prevent wear and corrosion

- 0.8% Molybdenum: For more strength as well as machinability

- 0.5% Manganese: For more hardness

- 0.4% Silicon: For more strength

- 0.45% Vanadium: For better wear resistance and improved hardenability

- 0.35% Niobium: For increased wear resistance power, hardness, and corrosion resistance ability

Hardness

Due to the huge amount of carbon, it is not surprising that CTS XHP is likely to be very hard. Typically, on the Rockwell scale, the hardness rating of this steel alloy is a minimum of 60 HRC. However, this rating can be a maximum of 64 HRC depending on the brand’s heat treatment for making the steel.

The range of 60 and 64 is also what you obtain with the D2 steel. Most good steel knives for daily use have a hardness rating between 57 and 59 HRC. This indicates that CTS XHP is typically harder than the average.

Properties

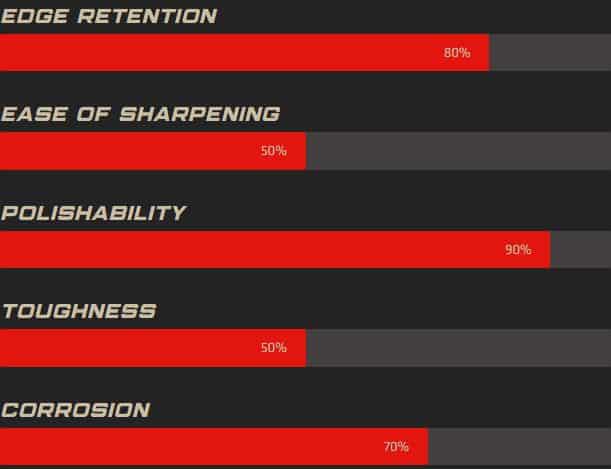

The chemical mix governs the properties of any steel. Due to high carbon, XHP steel ensures high edge-retention ability and corrosion resistance compared to other CTS variants. Following are its properties:

- Superb Wear Resistance: This is one of the expected properties, as this steel’s hardness is akin to that of the D2 steel. It will withstand daily wear and tear without distortion. It will also keep abrasion at bay, which usually triggers regular sharpening. This steel can last for a long time despite passing through different cycles of resharpening. It will not wear despite constant challenging uses.

- Excellent Edge Retention: This steel ensures incredible edge retention due to its extremely high level of hardness. You can use CTS XHP knives for months for cutting things and yet do not see any of its edge portions as dull. You can even rely on it to cut continuously all day long. Its ability to retain a sharp edge is better than that of S30V.

- Great Corrosion Resistance: This property of CTS XHP stainless steel is akin to 440C. It keeps corrosion and rust at bay due to the high content of chromium.

- Reasonably Tough: As a rule of thumb, most hard steels are not that tough. Hardness and toughness are inversely proportional. This means that they are more susceptible to chipping and brittleness. This also applies to CTS XHP steel. However, the CTS XHP toughness is surprising. It is tougher, meaning it is more powerful to keep chipping and cracking at bay than expected. While not meant for heavy or high-impact work done by long knives, this steel is ideal for making shorter blades.

- Ease of Sharpening: CTS XHP has a high hardness level, which has its benefits. However, it makes it challenging to sharpen this steel on the flip side. However, this is not a concern for those who have learned how to resharpen using different tools. Harder steels also exist, due to which the level of sharpening difficulty becomes moderate. If you use an advanced sharpener, sharpening this steel edge is not challenging.

Comparison With Other Knife Steel Options

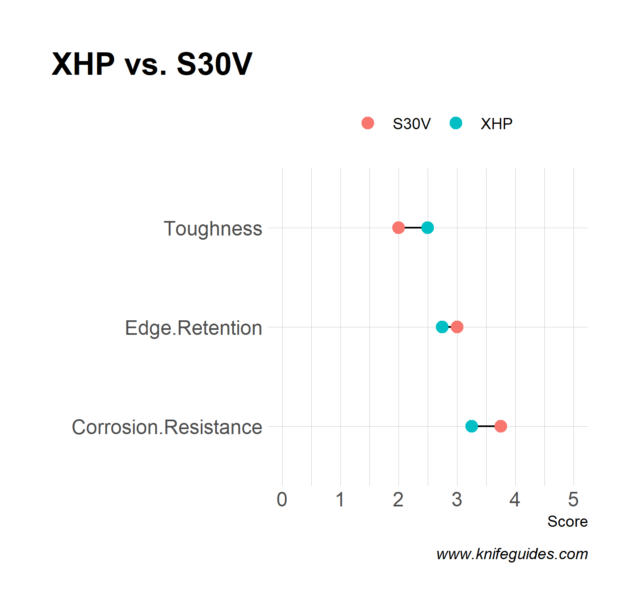

CTS XHP vs. S30V

Both the steels are premium, high-end options. However, CTS XHP ensures better edge retention, although S30V is better at corrosion resistance. Of the two, S30V is more readily available as well as popular.

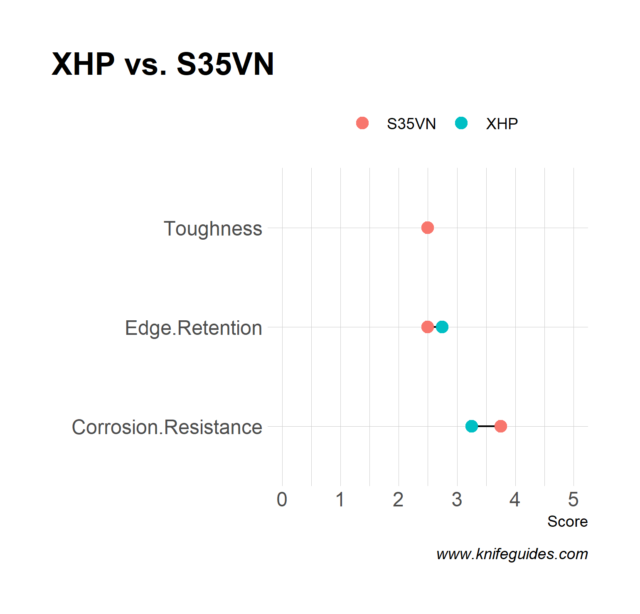

CTS XHP vs. S35VN

The latter steel is an upgraded form of S30V. CTS XHP wins over S35VN with slightly better edge retention. However, S35VN wins in terms of corrosion resistance.

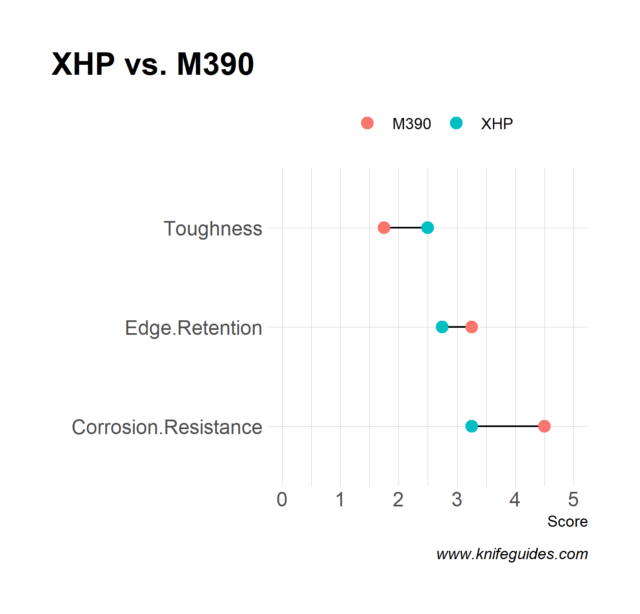

CTS XHP vs. M390

While both belong to premium steels, M390 belongs to the upper tier. It is known for ensuring better corrosion resistance and edge retention. However, sharpening it is difficult compared to CTS XHP.

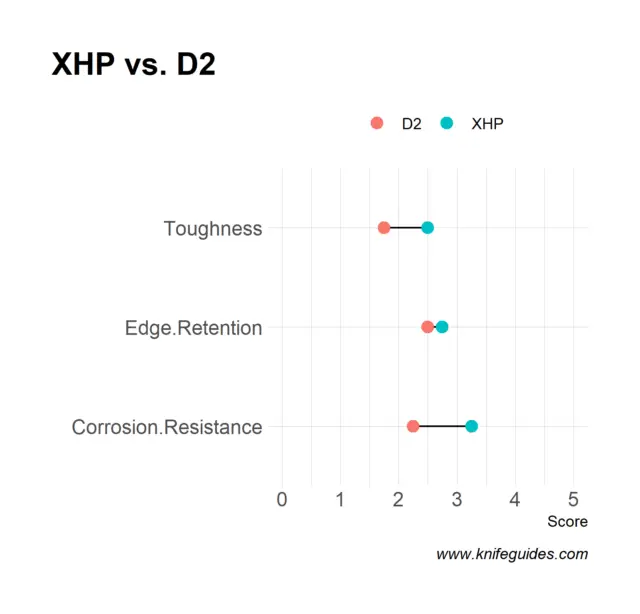

CTS XHP vs. D2

CTS XHP is more resistant to corrosion than the semi-stainless D2. However, in terms of edge retention, both are close.

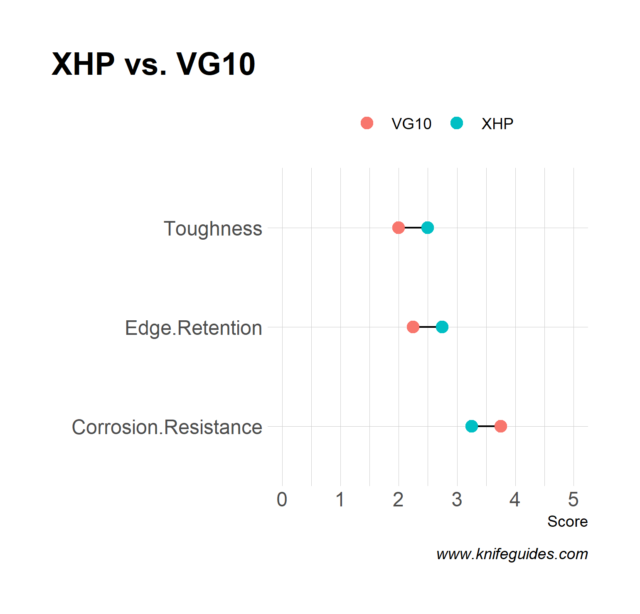

CTS XHP vs. VG10

VG10 is a great overall option due to its right balance of hardness and toughness. It is more resistant to corrosion and a bit easier to sharpen than CTS XHP. However, in terms of edge retention and toughness, XHP wins.

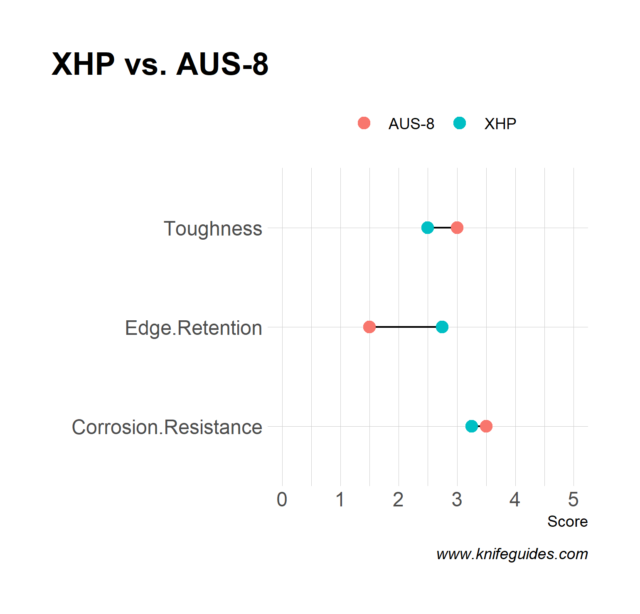

CTS XHP vs. AUS 8

The carpenter steel is far ahead in terms of hardness and edge retention. However, in terms of corrosion resistance, both are pretty close.

So, is CTS XHP a Good Knife Steel?

CTS XHP stainless steel is a good option if you are looking for superb edge retention, high wear resistance, and excellent corrosion resistance, along with the right level of toughness to keep chipping away. You can find many EDC knives made of this steel at reasonable prices.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.