(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Many steel knives swear by maximum durability. However, when used frequently, they do not last. This mostly applies to cheap knives. However, there are exceptions here. You will find steel knives that are affordable but last long. D2 steel knives are extremely durable than some high-end premium knives yet affordable.

What is D2 Steel?

D2 is air-hardening tool steel having high chromium, molybdenum, vanadium, and carbon elements. It refers to a die type of material, evident from the letter D in its name.

In the category of tool steels, D2 has the highest carbon content. Its typical appearance of a high-polish finish gives a feeling of a stainless steel type, although the chromium content is 11.5% to 12.0%.

According to many experts, any steel to be a type of stainless steel must have at least 13% chromium. Therefore, this tool steel is sometimes called semi-stainless steel.

D2 officially belongs to a tool steel group named high carbon, high chromium steels. It is also a part of the cold-work category of tool steels, as it is given the desired shape after cooling. As this steel is also made using the process of oil quenching or air quenching, it can retain its hardness.

Steel grades having high chromium high carbon were introduced as alternatives to high-speed steels in the early 20th century. They were similar to the D3 tool steel featuring 2.2% carbon. However, the amount of carbon was then brought down to 1.5%, and vanadium and molybdenum were added to boost hardenability and toughness.

This tool steel differs from CPM-D2, a relatively novel steel grade following the Crucible’s CPM methodology. This new steel was introduced to reduce the size of carbides for boosting corrosion resistance and toughness.

This high-carbon alloy steel is considered ideal for tools for which the users would prefer less frequent sharpening. At present, it is used for making deformation and cutting tools.

Chemical Composition

Following are the components of this high carbon, semi-stainless steel:

- 1.5% Carbon: For more hardness level as well as better resistance to wear as well as corrosion

- 12% Chromium: For more tensile strength, edge retention, and prevention of corrosion and wear

- 1.1% Vanadium: For better strength, wear and corrosion resistance, and toughness

- 0.9% Molybdenum: For more hardenability, strength, hardness, and toughness

- 0.45% Manganese: For more hardenability, forgeability, and wear resistance

- 0.40% Silicon: For more strength

- 0.03% Phosphorus: For more strength

- 0.02% Sulfur: For improved machinability

Steel Hardness

The hardness level of D2 steel ranges from 55 to 62 HRC on the Rockwell hardness scale. This range of hardness ensures boosted edge holding ability and wear resistance. The exact level of hardness varies as per the heating treatment applied.

Steel Properties

- Toughness: As this tool steel can have a rating of 62 HRC, it is considered quite hard. Thus, its level of toughness is low. The harder the steel, the less tough it is! However, the toughness level is not too low; it is enough to withstand some abuse without breaking or chipping. If you are looking for heavy-duty tasks such as batoning, it is ideal to consider other tougher steels.

- Terrific Wear Resistance: This is what makes it quite popular in the world of knives. It is considered the king of wear resistance by many knife users. The credit for this goes to the ideal mix of carbon, chromium, vanadium, and manganese. Due to extreme resistance to wear, a D2 steel knife is highly resistant to abrasion, unlike most carbon and stainless steel types.

- Excellent Edge Retention: This is another commendable property of this tool steel. Because of high hardness, you can expect great edge retention. The credit goes to the high carbon as well as chromium content. This high hardness level is a major factor contributing to sustaining a sharp edge for longer than most affordable steel. D2 steel knives will not disappoint you if you wish to avoid frequent sharpening.

- Okay Corrosion Resistance: Although D2 is not a pure stainless-steel option, the chromium content is quite close to the desired amount. Thus, D2 doesn’t perform as well as stainless steel when it comes to corrosion resistance. However, it resists corrosion better than many other non-stainless steels. Although susceptible to catching rust, this steel will not rust very quickly. Consider drying the knife every time after using it.

- Ease of Sharpening: The high hardness level makes it tough for anyone to sharpen a D2 knife. However, this does not mean you cannot sharpen it at all. Instead, it means that you will end up spending more time and effort in getting an ultra-sharp edge than that spent in sharpening softer steel grades. You will also need a diamond-based sharpener for better results.

Comparison With Other Knife Steel Options

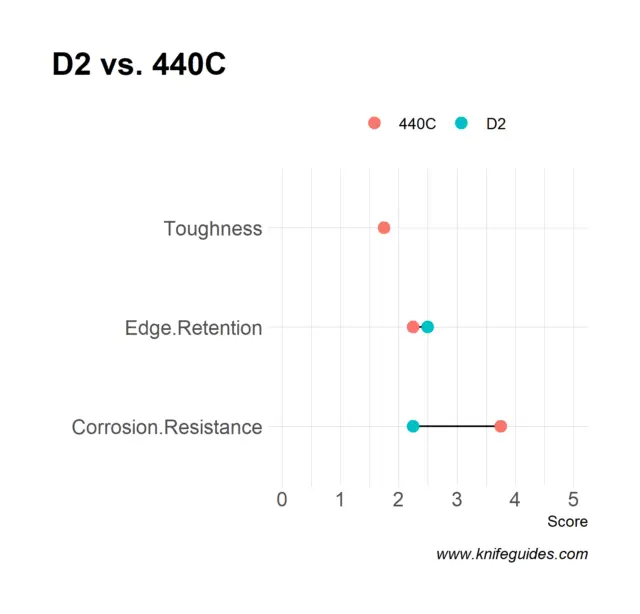

D2 vs. 440C

440C resists corrosion better than D2 because of more chromium and carbon content. However, in the case of edge retention, the semi-stainless steel wins as it is harder, by a small margin.

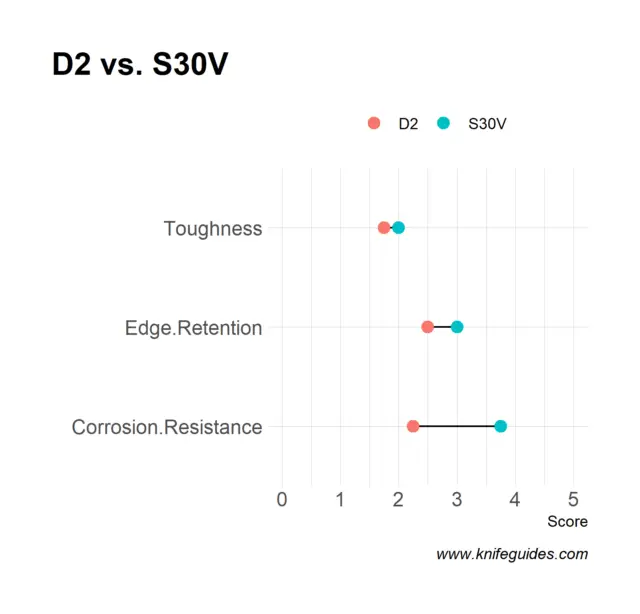

D2 vs. S30V

Made using the process of powder metallurgy, S30V has finer carbides ensuring terrific, uniform toughness. It is a premium-grade option that ensures better corrosion resistance and edge retention than D2. It is also easier to sharpen. However, due to the complicated metallurgy process, S30V is costlier.

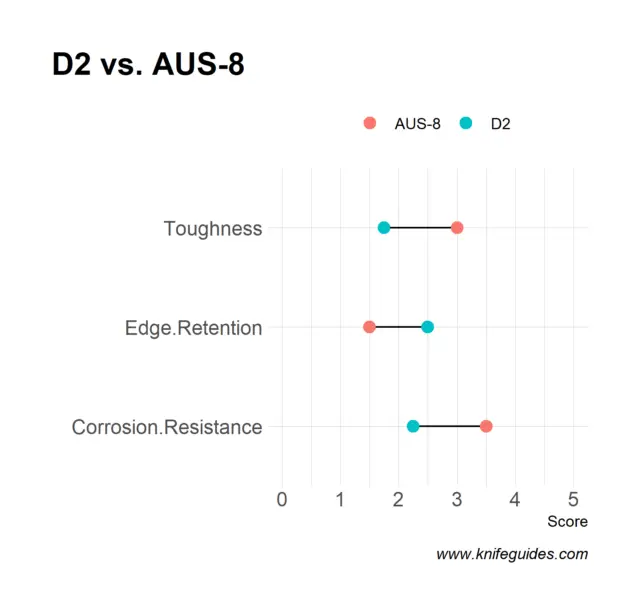

D2 vs. AUS 8

The latter one is a stainless steel alloy. Thus, AUS 8 can resist corrosion better than D2 and is very easy to sharpen. On the other hand, the tool steel has better edge retention due to its high hardness level.

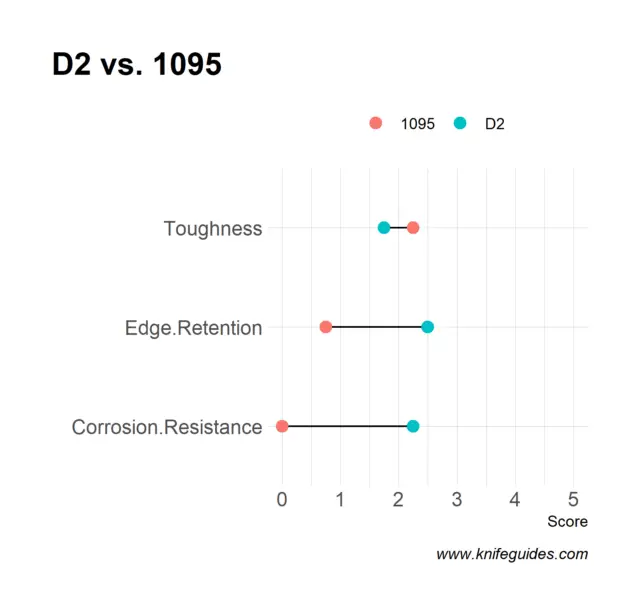

D2 vs. 1095

As a carbon alloy, 1095 is easier to sharpen. However, it cannot resist corrosion or rust. Due to higher carbide content, D2 resists wear and tear better than 1095. Nevertheless, 1095 is tougher because of finer carbides. Thus, semi-stainless steel is at more risk of chipping than 1095.

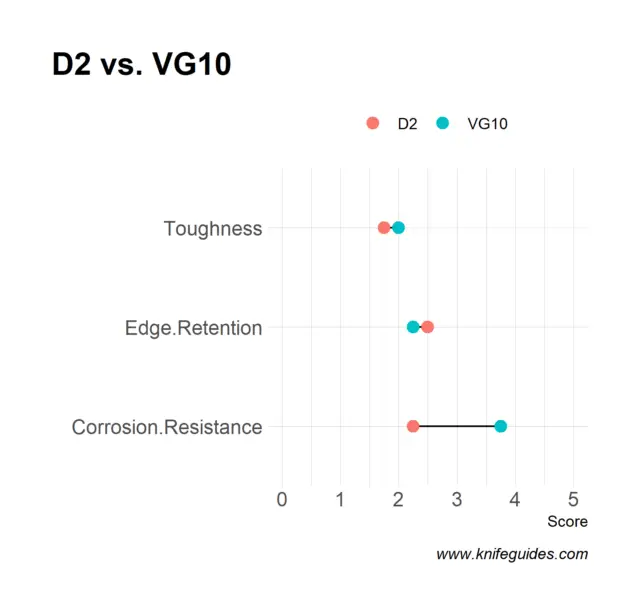

D2 vs. VG10

D2 wins over VG10 in terms of edge retention. However, VG10 is better for rust resistance and ease of sharpening.

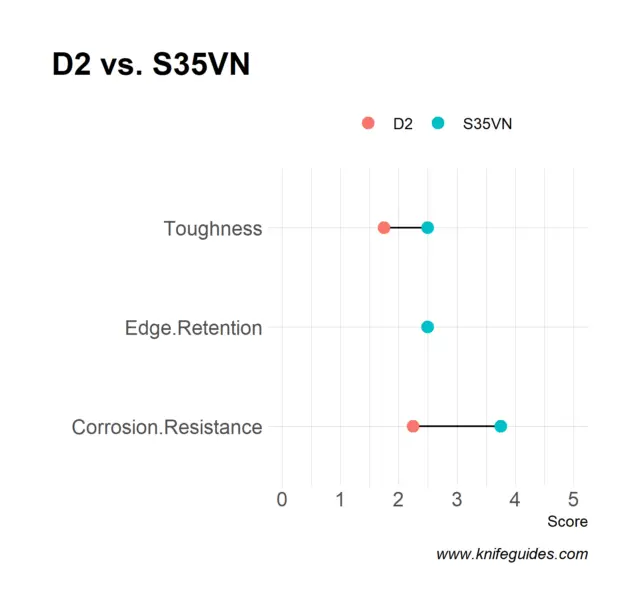

D2 vs. S35VN

Although both scores the same in edge retention, the CPM S35VN is tougher and is far better at resisting corrosion.

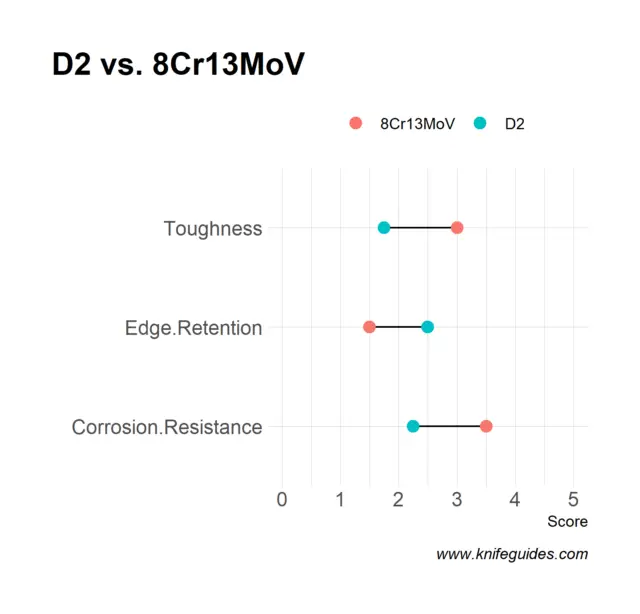

D2 vs. 8Cr13MoV

D2 is harder and is better at edge retention. On the other hand, the Chinese 8Cr13MoV is better at resisting corrosion and is tougher.

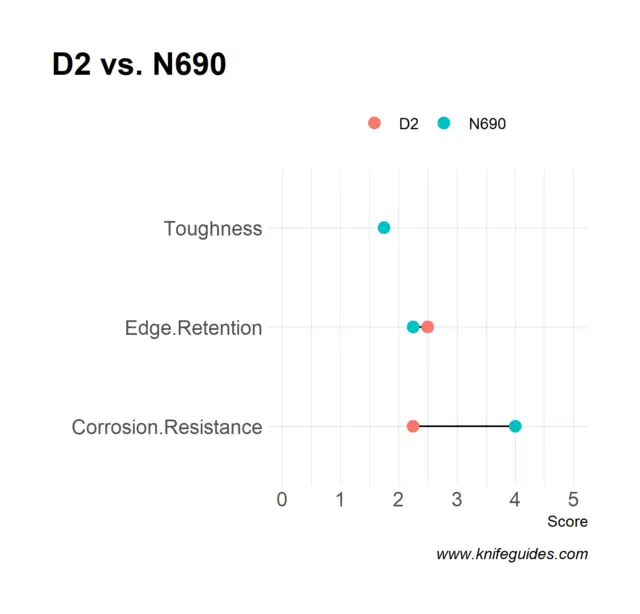

D2 vs. N690

Bohler N690 is far better at corrosion resistance. But both steels are pretty close in every other aspect.

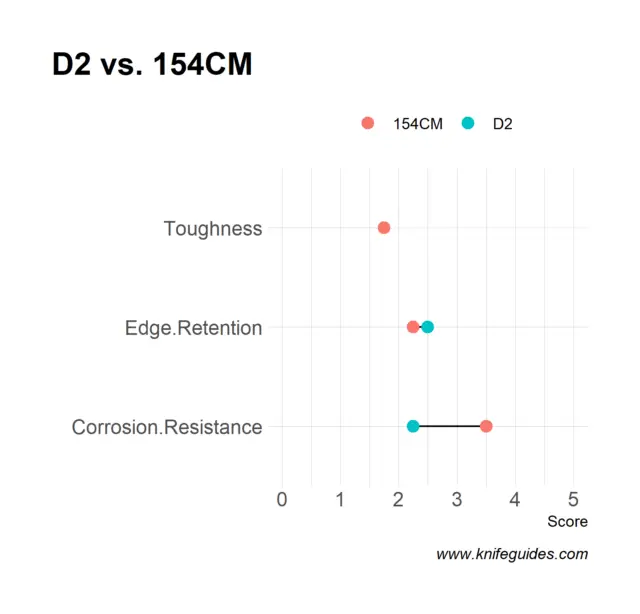

D2 vs. 154CM

154CM is much better at corrosion resistance. But both steels are pretty close in every other aspect.

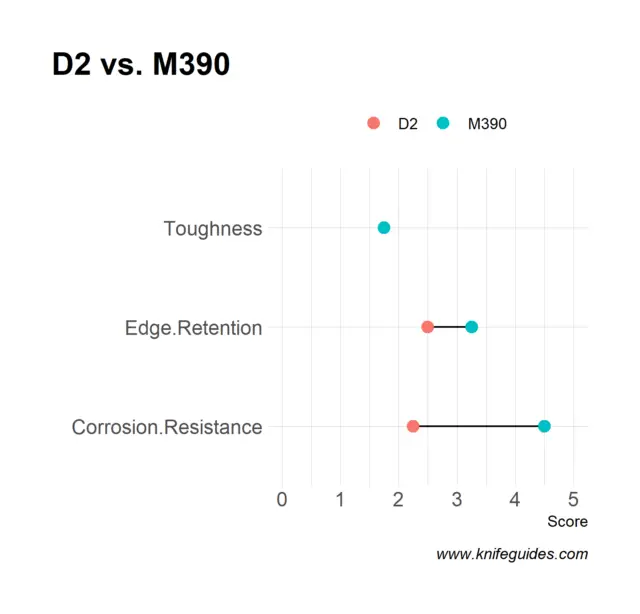

D2 vs. M390

M390 is a premium steel and is harder, better at edge retention, and far better at corrosion resistance.

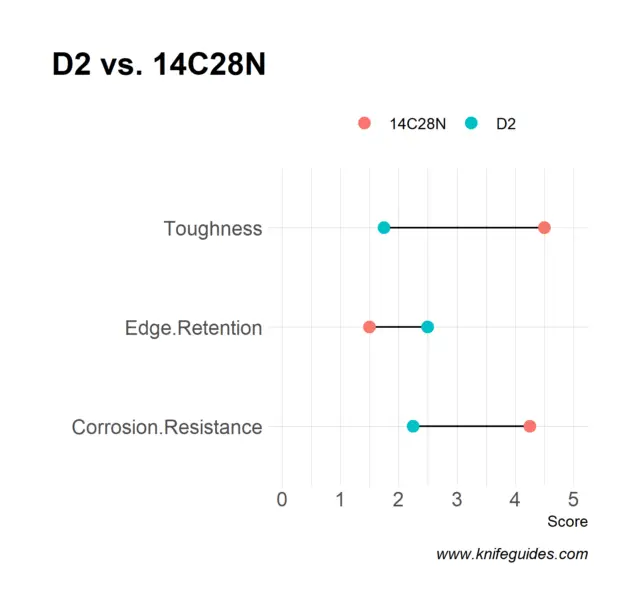

D2 vs. 14C28N

D2 is harder and better at edge retention compared to the Sandvik steel. But, on the other hand, the Swedish steel is far ahead in toughness and corrosion resistance.

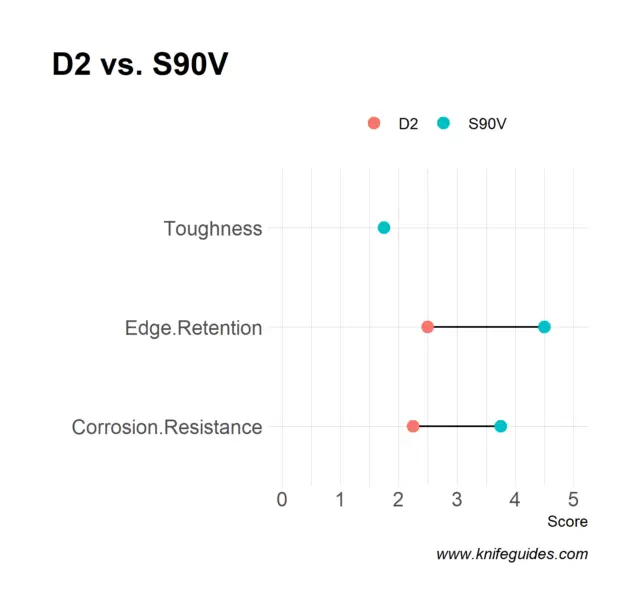

D2 vs. S90V

S90V is an expensive premium steel, unlike D2. It is harder and far ahead in corrosion resistance and edge retention.

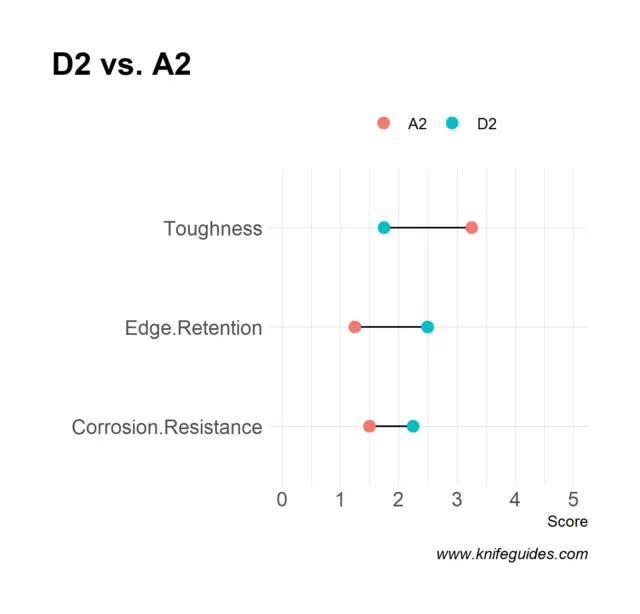

D2 vs. A2

A2 is an air-hardening tool steel as well. D2 is less tough than A2. But it is harder, better at edge retention, and corrosion resistance.

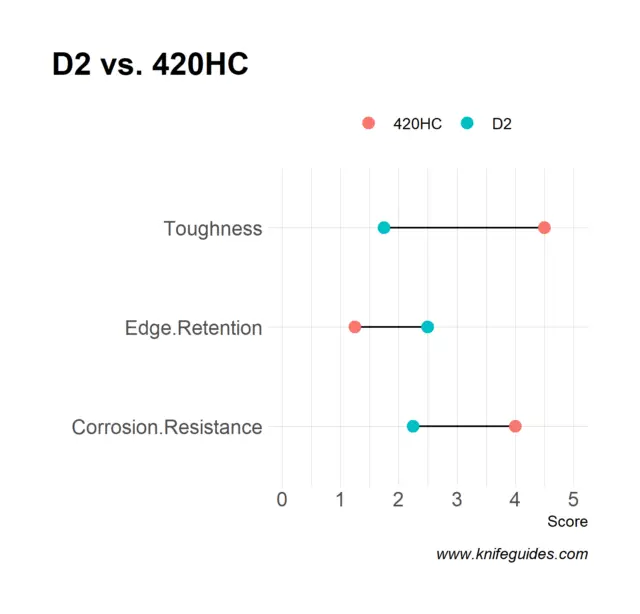

D2 vs. 420HC

D2 is harder and better at edge retention. But 420HC is far ahead in toughness and corrosion resistance.

So, is D2 Steel Good?

Yes, the D2 tool steel is a value for money choice for knives not intended for heavy-duty tasks such as batoning. It is known for its superb edge retention and extremely high wear resistance but offers relatively poor corrosion resistance compared to stainless steel.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.