(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Many of the knives from Spyderco Salt are made using H1 steel blades. As the name of the series indicates, these knives are made to work in saltwater environments while keeping corrosion and rust away. For many, H1 is synonymous with corrosion resistance.

Let’s explore more on this steel in detail.

What is H1 Steel?

H1 is a mid-range steel featuring complete resistance to corrosion in any natural environment. It is an austenitic stainless steel. It is manufactured in Japan by a company named Myodo Metal. Thus, it is also referred to as Myodo H1 there.

Chemical Composition

The basic structure of this austenitic stainless steel is quite unusual. It has very low carbon, high nickel, and some nitrogen with sufficient chromium. Following are the different elements of this specialty steel:

- 0.15% Carbon: For enhanced hardness as well as resistance to wear and corrosion

- 14% Chromium: For enhanced edge retention, tensile strength, and resistance to corrosion and wear

- 7% Nickel: For enhanced toughness

- 3.78% Silicon: For enhanced strength as well as resistance to corrosion

- 1.12% Manganese: For enhanced hardness and less brittleness

- 0.94% Molybdenum: For improved strength, machinability, and corrosion resistance, specifically pitting resistance

- 0.05% Nitrogen: For enhanced strength and edge retention ability

Hardness

According to the Crucible metallurgists, the hardness rating is around 57-58 HRC at the spine and 65 HRC (harder) at the edge. According to Spyderco forums, Crucible metallurgists tested a minimum of two Spyderco knives, one with H1 plain edge and the other with H1 SpyderEdge. According to them, although the hardness level of both spines was 58 HRC, the edges scored 65 HRC and 68 HRC, respectively.

Well, this is extremely high hardness. The steel does not show brittleness even at that high hardness level, according to the same source. The mix of molybdenum and silicon contents and the manufacturing process result in 57 HRC. However, some disagreement exists regarding the edge’s hardness.

H1 is work-hardening steel, meaning it gets harder as you use it. However, many knife users and experts disagree.

Properties

- Good Toughness: The hardness rating is 58 HRC. This is considered relatively low. If the hardness level is low, the toughness level will be high. So, H1 has good toughness when its hardness level is low. This steel has no brittle carbides but does contain soft and ductile ferrite, due to which one can expect its toughness level to be high. In other words, it will not chip or crack easily or quickly.

- Poor Wear Resistance: The ability to resist wear increases in proportion with increased hardness. So, H1’s wear resistance is poor since the hardness level is low. The lack of very hard carbides, relatively low hardness, and the presence of delta ferrite result in lower wear resistance performance than several other knife steels.

- Poor Edge Retention: H1’s edge holding ability is below AUS-8 and 8Cr13MoV because of its low wear resistance. It is reported that it can retain a sharp edge better if it is serrated.

- Great Corrosion Resistance: This is where this steel shines. Although there is not much carbon, the trivial amount of nitrogen acts like carbon and does not interact with chlorine to trigger rust. H1 is considered a level below the austenitic steels having 8% nickel and 18% chromium. However, the inclusion of molybdenum enhances corrosion resistance. Therefore, H1 is ideal for knives to be used in and around saltwater. This is because high molybdenum content is required for keeping rust away at continuous exposure to saltwater. Indeed, steels like 316 or 304 are even better at corrosion resistance. Another reason why this austenitic stainless steel offers high corrosion resistance is that almost all the chromium content is available as chromium in solution instead of chromium carbide like in many other steels.

- Ease of Sharpening: It is easy to sharpen an H1 steel blade because of its low hardness. A simple sharpener will give you a sharp edge.

Comparison With Other Knife Steel Options

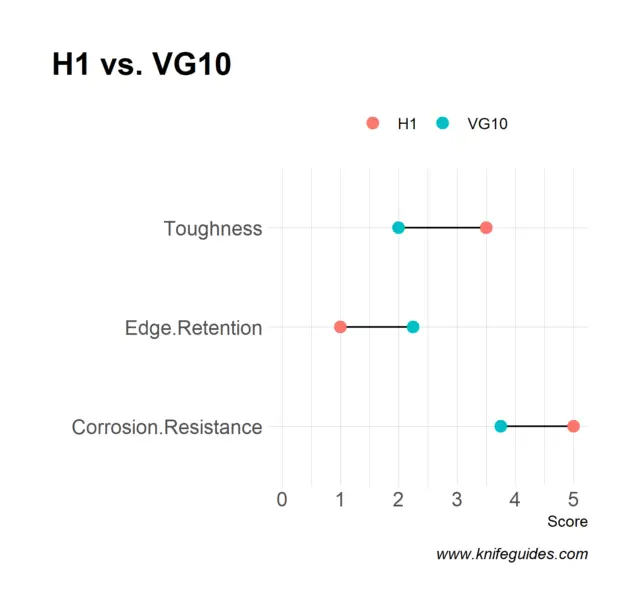

H1 vs. VG10

VG10 wins in terms of edge retention. However, H1 takes it over in toughness, corrosion resistance, and ease of sharpening.

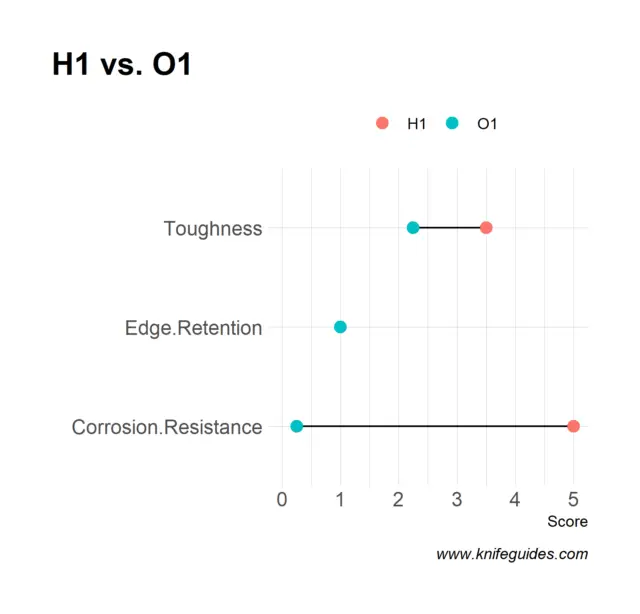

H1 vs. O1

Regarding corrosion resistance and ease of sharpening, H1 is a far better choice than O1. On the other hand, O1 is tougher.

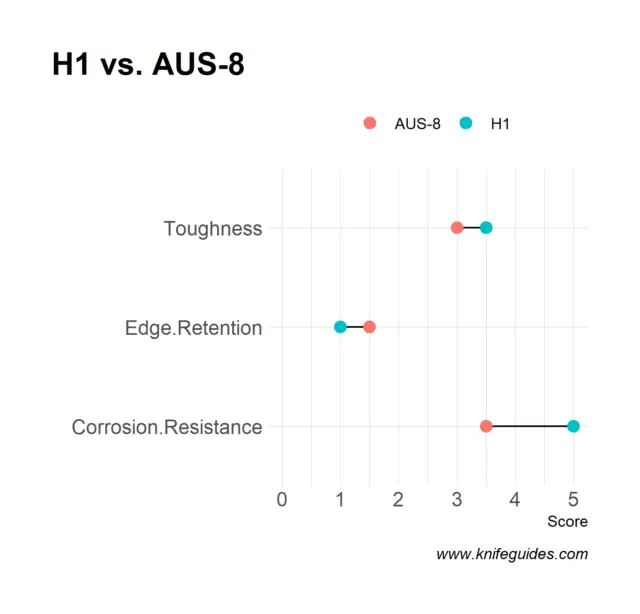

H1 vs. AUS-8

H1 is tougher and resists corrosion far better than AUS-8. However, AUS-8 is slightly better in retaining a sharp edge.

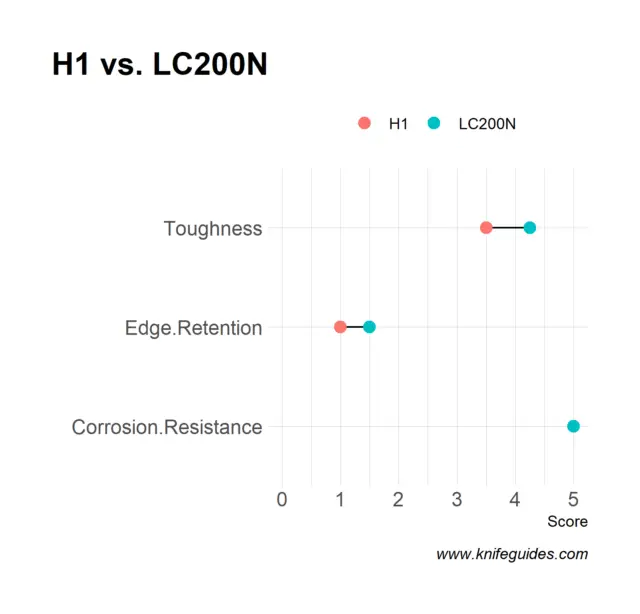

H1 vs. LC200N

LC200N, like H1, is known for its superior corrosion resistance. However, in terms of edge retention and toughness, LC200N is a better choice.

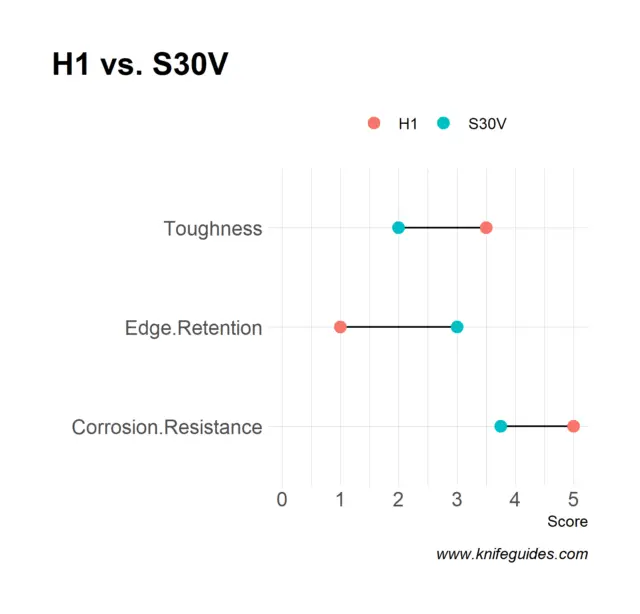

H1 vs. S30V

S30V is a high-end steel with a higher hardness rating and good corrosion resistance. But in terms of corrosion resistance, the CPM steel is not a match to the H1. But in terms of edge retention, S30V is far ahead.

So, is H1 Steel Good?

H1 is the ultimate knife steel in terms of corrosion resistance. Look no further if you’re interested in the perfect fishing, diving, or marine knife. The expensive LC200N is the closest in terms of its corrosion resistance. However, In terms of hardness and edge retention, this is one of the worst steel.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.