(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Familiar with popular tool steels for knives? If yes, you may have come across the O1 tool steel. It is a highly popular material that several custom knife makers forge knives with. However, this is not enough to decide whether it is the right steel for your knives or not. For that, you need to know its chemical composition, properties, and how well it performs when compared to other competitive steel options. So, let’s explore these details.

What is O1 Steel?

O1 steel is a classic, low-end grade known popularly as oil hardening tool steel. Introduced in 1905 by Halcomb (now acquired by the American-based Crucible company), it is a part of the O group of steels. The letter O means Oil quenching; whereas, 1 signifies that it is the precursor of other O steels in the group.

Tool steel is a carbon alloy that has some properties suitable for the production of tools, like hand tools and machine dies. O1 tool steel is quenched in oil, not in water. This general-purpose material is preferable when other steels lack the desired level of hardness. Yes, tool steels usually have remarkable hardness and are known to sustain their form even at high temperatures.

As one of the best tool steel options, O1 is widely used for making various types of blades. It is used for making measuring tools, punches, knives, and industrial machine knives.

Chemical Composition

With a high amount of carbon, this is a high-carbon steel grade. At the same time, because it contains a low amount of chromium, it is not stainless steel. Following are the contents of O1 high carbon steel:

- 1% Carbon: For an enhanced hardness level as well as improved ability to keep wear or corrosion away

- 0.6% Chromium: For terrific tensile strength, great edge retention, and prevention of wear and corrosion

- 1.4% Manganese: For more hardness, forgeability, and dimensional stability

- 0.6% Tungsten: For better resistance to wear and enhanced hardness

- 0.5% Silicon: For better strength

- 0.3% Nickel: For a high level of toughness

- 0.3% Vanadium: For better resistance to wear as well as hardenability

- 0.03% Sulfur: For better machinability

- 0.03% Phosphorus: For more strength

In terms of chemical composition, the O1 equivalent is the AISI L6 steel. However, L6 is tougher due to a higher content of nickel.

Steel Hardness

Due to high carbon content, the hardness rating of O1 steel ranges from 57 to 62 HRC. On the Rockwell scale, the typical rating is 57 HRC. However, this rating tends to differ from one sheet to another depending on the type of heat treatment process the manufacturer has implemented.

This steel can be very hard. While 57 HRC is suitable for EDC knives, the greater ratings are ideal for outdoor knives, especially used for camping and cutting tough things.

Steel Properties

The presence of the alloying elements directly affects the properties as well as the performance of the steel. Following are its properties:

- Surprising Toughness: A hard steel usually is less tough. Thus, such a knife blade tends to be brittle, due to which it is more susceptible to chipping. However, this is not the case with O1. Despite being hard, it has decent toughness to keep chipping at bay. Thus, it is ideal steel for survival, bushcrafting, and camping knives. At the same time, it is hard enough to cut thick or hard materials. This steel can easily carve with wood.

- Excellent Wear/Abrasions Resistance: With the hardness level this steel comes with, you can expect it to keep abrasions and wear impact at bay. This is one of the reasons why this tool steel is used for making different types of knives. The credit for this goes to the right mix of carbon, vanadium, and manganese. In short, O1 tool steel knives will last for a long period despite frequent use.

- Great Edge Retention: Due to a high level of hardness, O1 ensures superb edge retention. These knives can retain their sharp edge for a long time. This is another reason why this steel is used for making outdoor knives.

- Not Good Corrosion Resistance: This is where the O1 tool steel for knives lacks. It does not have good anti-corrosion ability. This is because of the very low chromium content in it. That said, you need to take good care like keeping it dry and lubricated to keep corrosion and rust at bay.

- Ease of Sharpness: Although hard, this tool steel is easy to sharpen. This steel takes a fine edge easily at the time of manufacturing a knife and retains it for a long time. Beginners with little or no sharpening skills will find it easy to sharpen O1 steel knives using a standard sharpener. As mentioned before, it also retains a sharp edge for a long time.

Comparison with Other Knife Steel Options

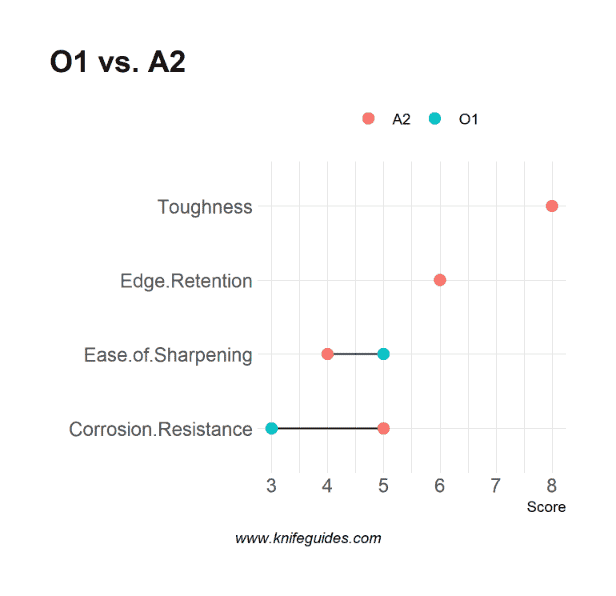

O1 vs A2

O1 achieves a keener edge more easily and requires less effort to sharpen than A2. A2 wins when it comes to resisting corrosion due to more chromium content.

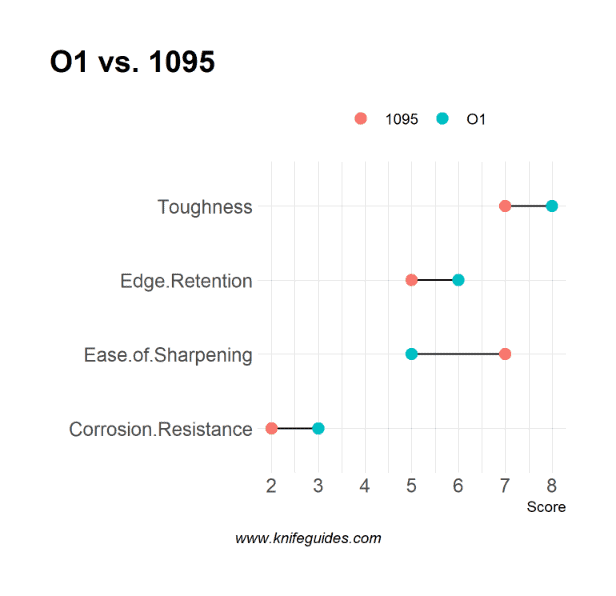

O1 vs 1095

The latter steel has no chromium content. This certainly gives the tool steel an edge. It has better corrosion resistance, wear resistance, and toughness compared to 1095. Although sharpening 1095 is relatively easier. Even when it comes to machinability, O1 is a better option.

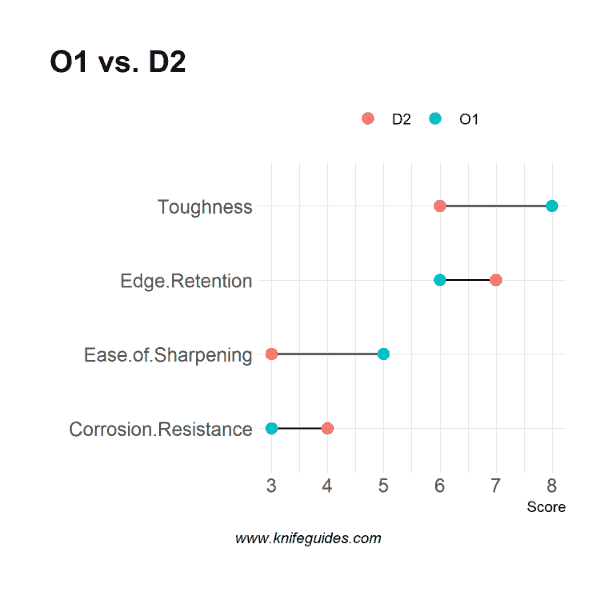

O1 vs D2

D2 is an air-hardened option with more chromium content. Thus, it ensures better corrosion resistance, wear resistance, and edge retention. However, O1 is tougher and easier to sharpen.

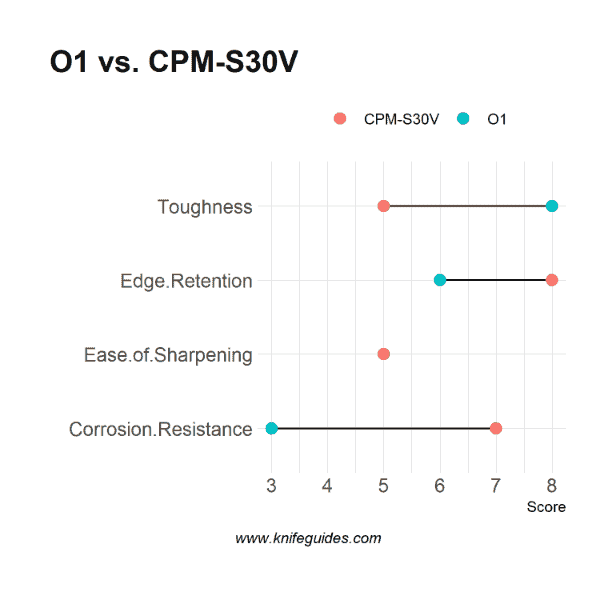

O1 vs S30V

S30V is a winner in terms of edge retention as well as corrosion resistance performance. On the other hand, O1 is tougher and is affordable than S30V.

O1 vs 1084

Both the steel grades are considered reliable for making knives due to their versatility. Nevertheless, O1 is harder and ensures better resistance to wear than 1084 because of the presence of tungsten. On the flip side, it is expensive than 1084.

Top O1 Tool Steel Knives

| Image | Title | Price | Buy |

|---|---|---|---|

| LT Wright Knives SOSPES Scandi Grind | Check Price on Amazon | |

| Enzo Bobtail 80 Fixed Blade Birch | Check Price on Amazon | |

| Ontario Knife Company 8696 | Check Price on Amazon | |

| Boker Patina Chef's Knife | Check Price on Amazon | |

| Handmade Hunting Knife | Check Price on Amazon |

So, is O1 a Good Knife Steel?

Yes, O1 is a good steel for knives due to its great properties such as high hardness, high toughness, superb wear resistance, and great retention of a sharp edge. Its only drawback is poor corrosion resistance. However, if you keep your knife dry and lubricated, rust and corrosion stay away. Custom makers prefer this steel for its great performance. The steel comes at a moderate price compared to the higher-end steel grades.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.