(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Have you been using kitchen knives made in Japan? If yes, then you have most probably used the VG10 steel blades. This steel is highly popular in Japan, wherein it is widely used for making kitchen knives.

However, outside Japan, knife makers are also using it for making pocket knives, EDC knives, and tactical knives. As a result, it is not uncommon to spot a folder with a VG-10 stamp on its blade from esteemed brands such as Benchmade or Spyderco.

What is VG10 stainless steel?

Also known as VG 10 or VG-10, VG10 refers to high-carbon Japanese steel made by Tafeku Special Steel. The name is a designation for a special type of stainless steel. The letter ‘G’ stands for ‘gold standard.’

So, what is this gold standard? Most knives have blades made using either stainless steel or carbon steel. Carbon blades are hard but take no time to rust. On the other hand, stainless blades do not rust quickly but are not as sharp or hard as carbon ones. However, the Japanese steel experts came up with an idea to obtain the best of both steel types. This resulted in VG-10 steel that contains both stainless and carbon constituents.

Due to its gold-standard quality, it got the name VG10, meaning V-Gold-10. It is also referred to as V-Kin-10, as Kin in Japanese means Gold.

This steel has emerged recently after the Japanese steel experts made a lot of improvements to VG1 steel. Apart from making knife blades, it is also used in making amazing designs on the blades at the time of tempering.

Chemical Composition

The VG10 steel contains a high amount of carbon. Further, it has a sufficient amount of chromium, to be called stainless steel. Following are the components that make up this steel:

- 15.5 chromium for edge retention, tensile strength, and improved resistance to wear as well as corrosion

- 1.5% cobalt for an improved individual impact of all other ingredients

- 1.2% molybdenum for better strength as well as manufacturing ability or machinability

- 1.05% carbon for enhanced resistance to wear and corrosion and better hardness

- 0.5% manganese for improved hardness

- 0.03% phosphorus for boosted strength

- 0.3% vanadium for enhanced hardness as well as resistance to wear

Hardness

VG10 is pretty hard as compared to other stainless-steel variants. This is due to more than 1% carbon in its chemical composition. When the Japanese makers produced VG1, they composed it to become a bit softer. VG-10 is not soft at all.

The hardness rating ranges between 56 and 60 because of the high carbon content. The exact rating differs from one maker to another as per the heat treatment process used. The blade material’s hardness determines its ability to keep abrasion and rust at bay. Further, it impacts the ability of the blade to retain the sharp edge.

VG-10 Stainless Steel Properties

The chemical composition of this stainless steel governs its properties. Following are its most significant properties that you can expect from VG-10 steel knives:

- Good Edge Retention: This is one of the big benefits of this steel. It can retain the sharp cutting edge despite using its edge for a long time. This is attributed to the presence of carbon, cobalt, chromium, and molybdenum, whose joined functioning ensures impressive edge retention. As a result, there is no need to sharpen the edge after every few days of use!

- Excellent Resistance to Corrosion: This is another big benefit you get from this steel. The credit goes to its high amount of chromium, up to 15.5%, to render it high-carbon stainless steel. Thus, VG-10 can easily keep rust or corrosion at bay in aquatic or humid environments. Well, this is only possible if you take care of the blade by keeping it dry. This is because it may not be completely corrosion-resistant.

- Superb Wear Resistance: VG10 is a high-end steel variant. It has sufficient chromium and high carbon, due to which it is admired for its power of great wear resistance.

- Sharpness: Due to the high level of hardness, many people wonder whether the VG10 steel is easy to sharpen or not. Well, you can easily sharpen a knife blade made up of this steel. Although hard, there is a good balance in its chemical composition that maintains sharpness.

- Toughness: Toughness is the ability to endure impact and lateral forces responsible for chipping or breaking. The more the hardness of steel, the lower is its toughness. Although this is a rule, it does not hold up well in the case of VG-10. Although hard, this steel has a good toughness level to uphold its performance in tough conditions.

Comparison with Other Knife Steel Options

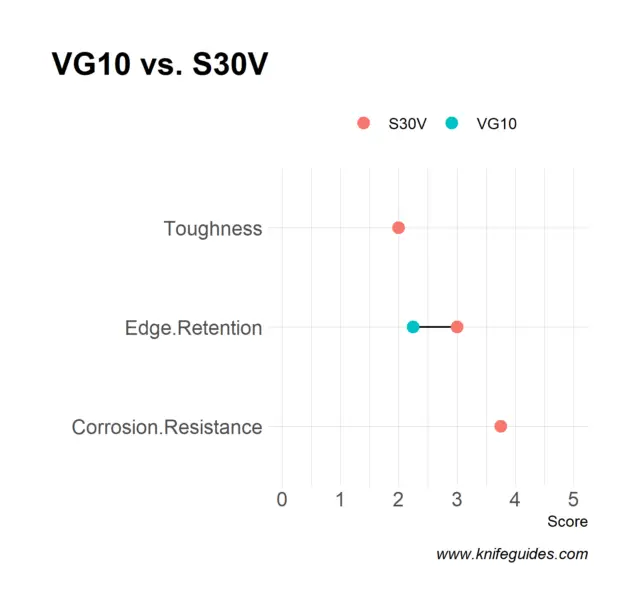

VG10 vs. S30V

These steel variants rank the same for corrosion resistance and toughness. However, when it comes to edge retention, S30V ranks higher.

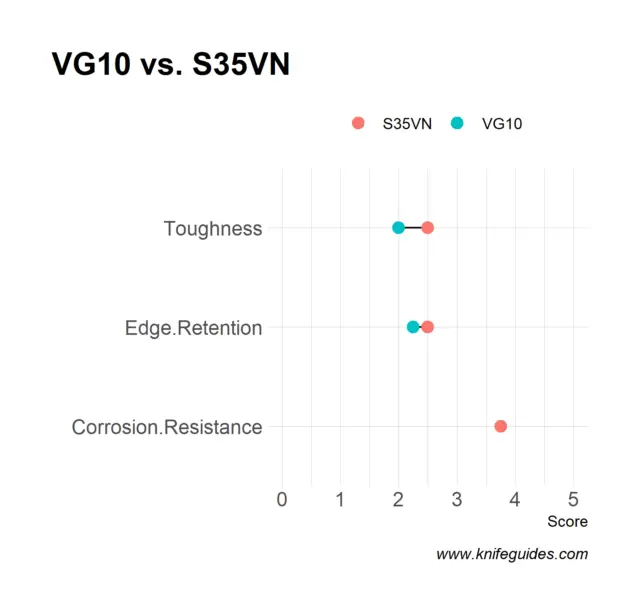

VG10 vs. S35VN

VG10 is harder than S35VN. Apart from that, both compete closely in terms of ease of sharpening, edge retention, and corrosion resistance.

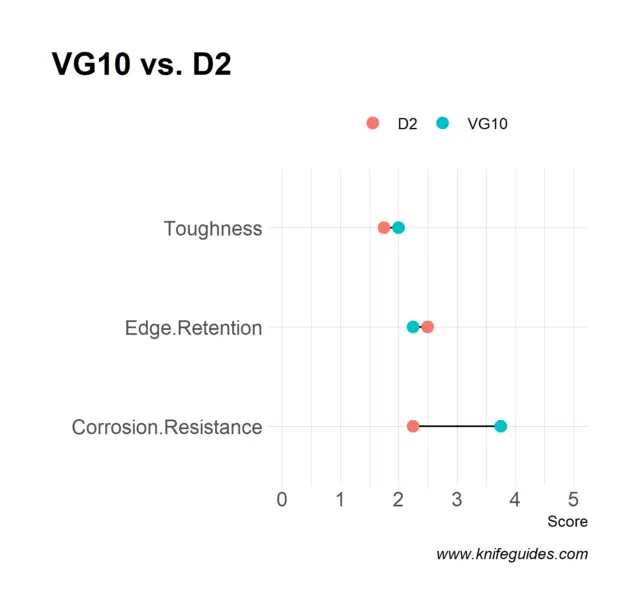

VG10 vs. D2

VG10 wins the race when it comes to ease of sharpness and resistance to corrosion. However, D2 is slightly harder than VG-10 due to its higher carbon content.

VG10 vs. SG2

Both of them come from the same steel maker. Also known as Super Gold 2, SG2 has more chromium and vanadium, hence better at resisting wear and corrosion than VG10.

VG-10 vs. VG1

While VG10 is commonly used for making work tools and knives, VG1 is widely found in collectible knives and swords. VG1 is a lot tougher, due to which it is also more brittle. Further, it is not a type of stainless steel, as it does not have a sufficient amount of chromium.

While the performance is not as good as VG10 for a knife blade, VG1 blades are comparatively more expensive. Therefore, if you choose to buy one, you will pay more for less performance satisfaction. Thus, it is better to select VG-10 over VG1 for your knives.

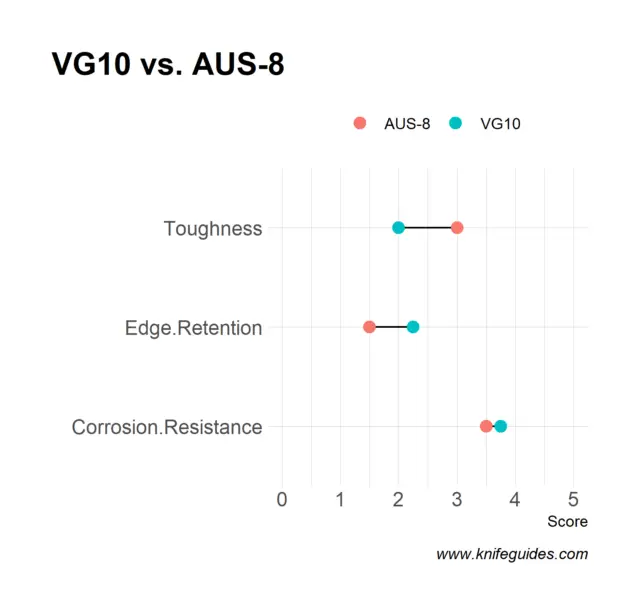

VG10 vs. AUS 8

Both the steel options are made in Japan. However, the AUS 8 steel belongs to lower-tier – upscale midrange, hence affordable. This affordability is also attributed to its edge retention ability, which is not as good as the VG10 stainless steel. Moreover, AUS 8 is also not as corrosion-resistant as VG10.

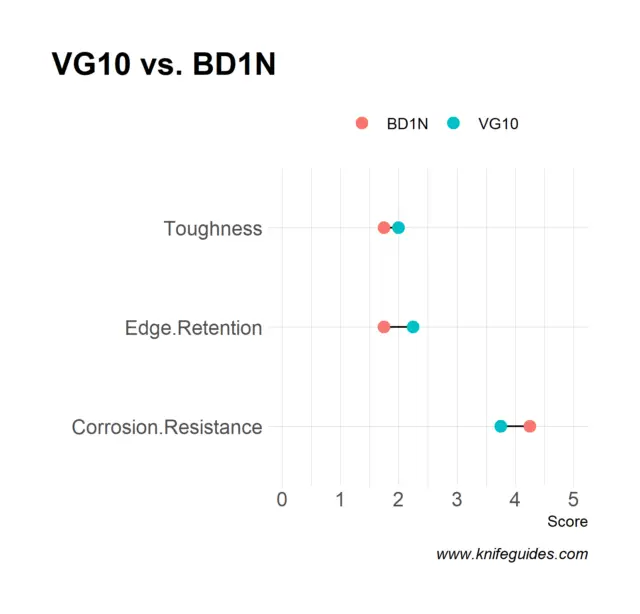

VG10 vs. CTS BD1N

Also known as BD1, in which nitrogen substitutes vanadium, BD1N resists corrosion much better. However, VG-10 sustains an edge better. In terms of ease of sharpening, both have an equal rating.

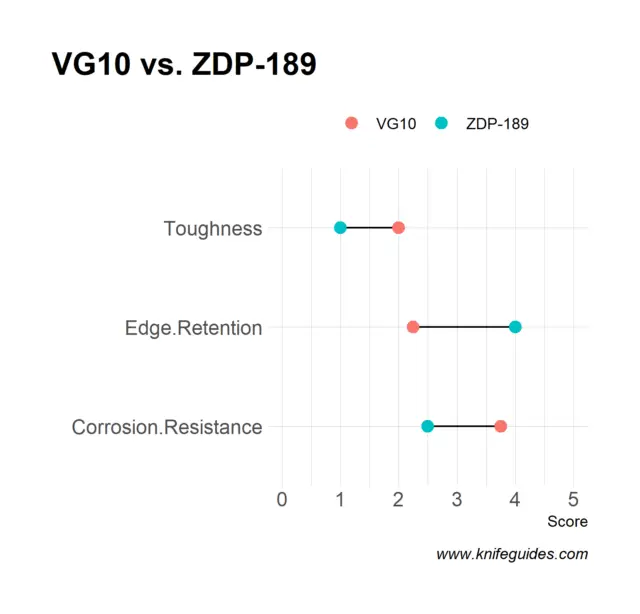

VG-10 vs. ZDP-189

This may not seem a truly fair comparison. This is because ZDP-189 belongs to the ultra-premium group of steels. With a rating of up to 66 HRC, ZDP-189 is better at sustaining a sharp edge but is quite difficult to sharpen.

Despite having 20% chromium, ZDP-189 is also not great at resistance to rust or corrosion. This is because most carbon combines with chromium, leaving hardly any free chromium to fight against corrosion.

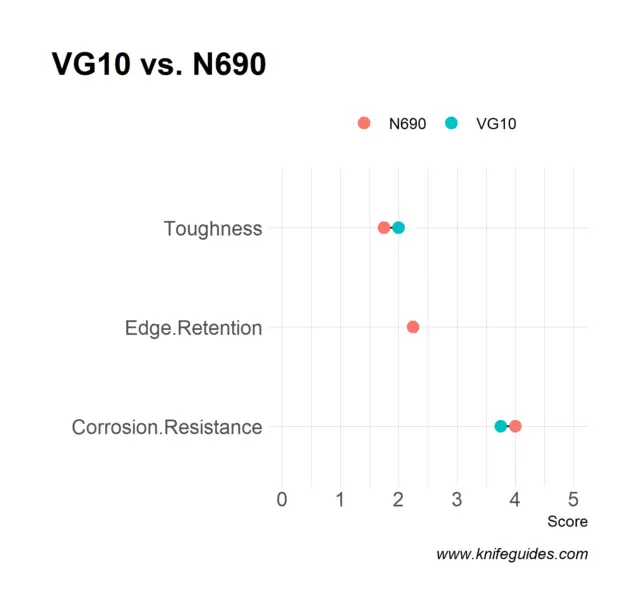

VG10 vs. N690

Bohler N690 and VG10 are pretty close in all aspects, as evident in the graph below.

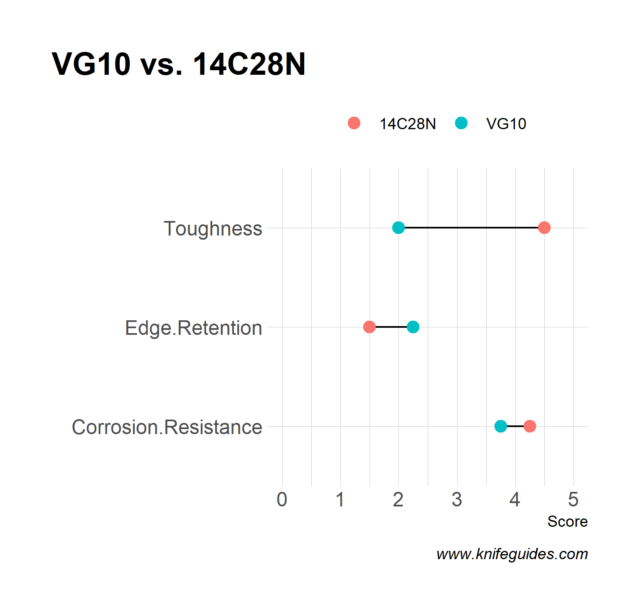

VG10 vs. 14C28N

The Sandvik steel is tougher and is better at corrosion resistance. Consequentially VG10 is harder and much better at retaining the edge.

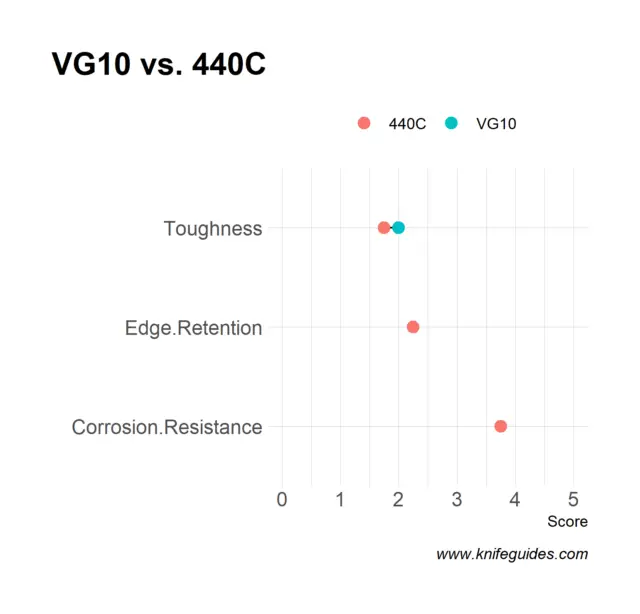

VG10 vs. 440C

Both the Japanese and American steel are almost identical in all the performance aspects.

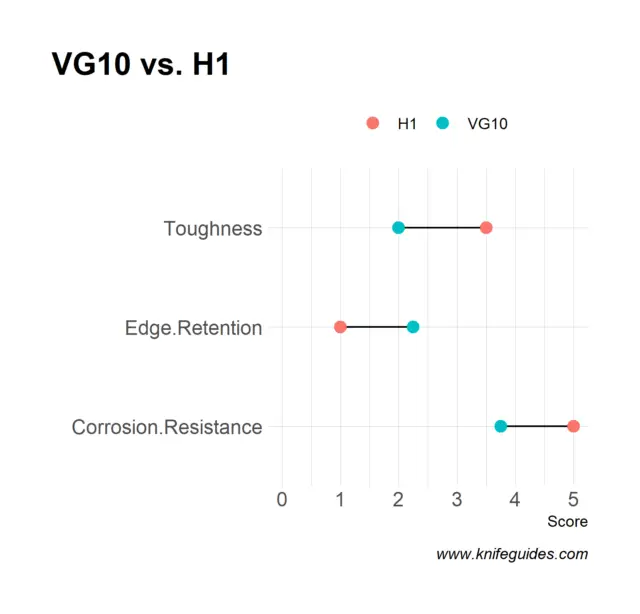

VG10 vs. H1

H1 is known for its extraordinary corrosion resistance. But in terms of hardness and edge retention, VG10 is far ahead. Consequentially H1 is tougher and is easier to sharpen.

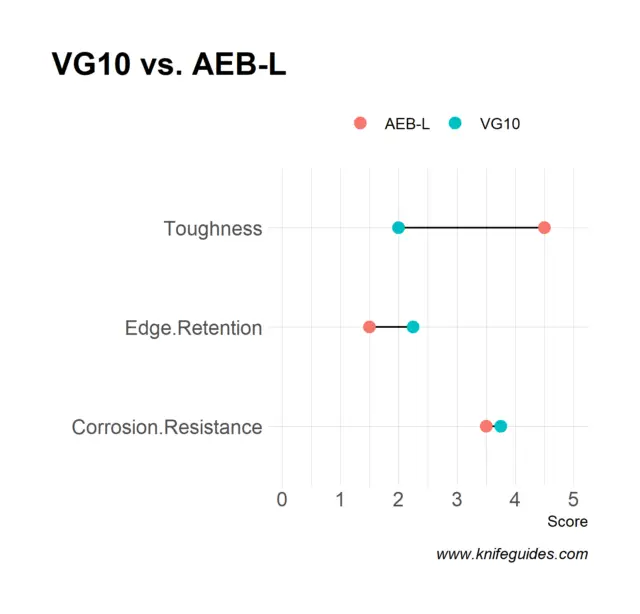

VG10 vs. AEB-L

Uddeholm AEB-L has been here for almost a century. It is a high toughness steel with poor edge retention capability compared to the Japanese steel.

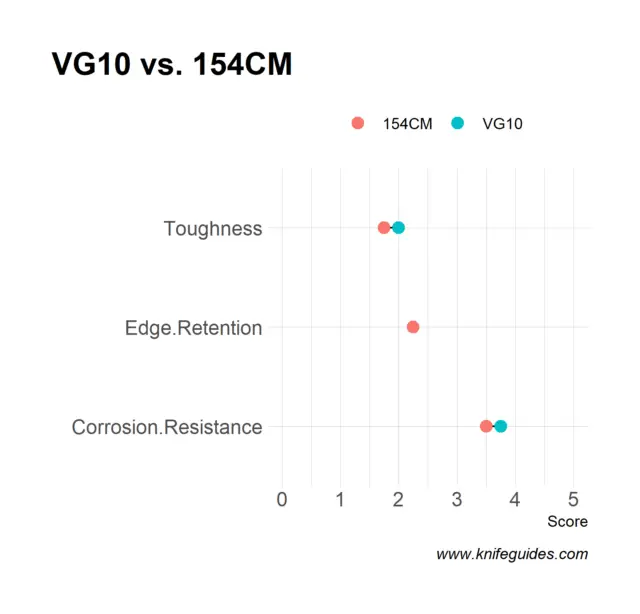

VG10 vs. 154CM

154CM and VG10 are pretty identical in all performance aspects.

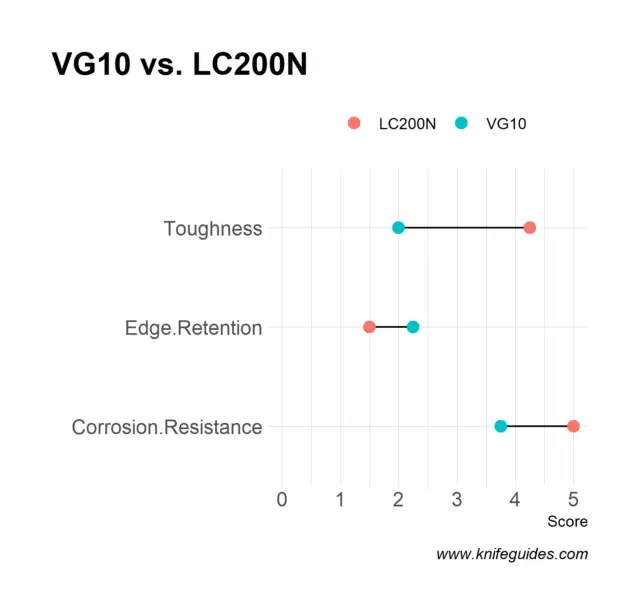

VG10 vs. LC200N

LC200N, also known as Cronidur 30, is known for its exceptional corrosion resistance and very toughness. However, it is a softer steel option; hence it is not good at retaining a sharp edge.

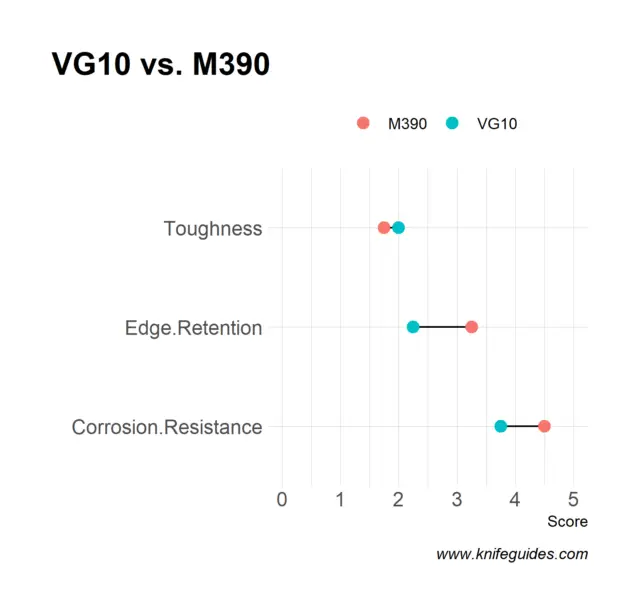

VG10 vs. M390

Bohler M390 is a super steel that is much costlier than the Japanese steel. However, it is harder and much better at edge retention. It also fares better in terms of corrosion resistance.

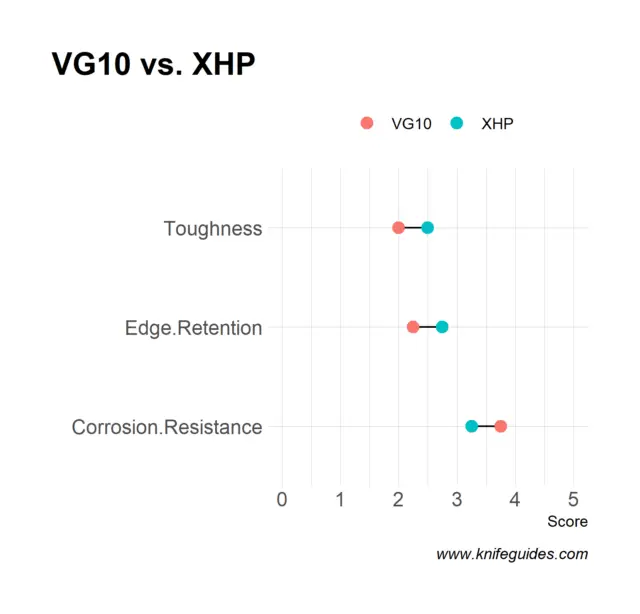

VG10 vs. CTS-XHP

CTS-XHP is a high-end steel from Carpenter technologies. It is better at edge retention and toughness, but the Japanese steel wins in corrosion resistance.

Is VG10 a Good Steel Material for Your Knives?

VG10 is a good knife steel option for those looking for an ideal mix of wear and corrosion resistance, excellent edge retention, ease of sharpening, and balanced hardness and toughness. In addition, it is a good choice for working in a humid setting. Finally, it is a value for money knife steel.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.