(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

A2 steel has been in use for quite a long time for creating knives. Famous knife makers such as Mike Snody, Aaron Gough, Rob Criswell, and John Fitzen have been using it for making custom combat knives. Aaron Gough also makes his survival or camping knives made using this American steel. Even famous knife brands such as Bark River and Black Wolf use A2 steel in their knives.

This post details its properties and performance in comparison with other promising steels. So, let’s explore!

What is A2 Steel?

AISI A2 is a tool steel that belongs to the cold works steels of the ‘A’ group. It is an air-hardening medium alloy steel from Crucible. The letter A in the name stands for air-hardening.

A2 is admired for its moderate wear resistance ability, high toughness, and ease of machinability. It has been widely used in a myriad of cold work applications where moderately high abrasion resistance is required but where higher-chromium, high-carbon steels are susceptible to cracking and chipping.

The tool steel is easy to work with and is primarily used in making hammers, dowel pins, woodworking cutting tools, chuck jaws, and dies. In the knife industry, A2 is used in making hiking, hunting, combat, camping, and survival knives.

Chemical Composition

A2 contains a high amount of carbon, which makes it high-carbon steel. It also has enough chromium to achieve a high level of hardness with good dimensional stability after the heat treatment. However, the chromium level is insufficient to make it stainless. Following are the components of this tool steel:

- 1.05% Carbon: For improved wear as well as abrasion resistance, tensile strength, and hardness

- 5.50% Chromium: For improved tensile strength, toughness, and resistance to corrosion

- 1.40% Molybdenum: For improved toughness and hardness

- 1.00% Manganese: For improved wear resistance, tensile strength, and hardenability

- 0.50% Silicon: For improved strength and resistance to corrosion

- 0.30% Nickel: For more toughness, while decreasing hardness

- 0.25% Vanadium: For more toughness, wear resistance, and steel strength

- 0.25% Copper: For better resistance to corrosion by keeping oxidation away

- 0.030% Phosphorus: For better hardness, strength, and machinability

- 0.030% Sulfur: For better machinability

There are a few A2 tool steel equivalents with similar chemical composition and performance. One of them is Aichi DKD12, which is a Japanese form of D2. Another famous equivalent is GB Cr5Mo1V from China, which is air-hardening tool steel with fair wear-resistance ability. Other equivalents are SKD12 from Japan, and 1.2363/X100CrMoV5 from Europe.

Steel Hardness

On the Rockwell scale, A2 steel has a hardness rating in the range of 57 HRC to 62 HRC. The exact rating varies as per the process of heat treatment. This range of hardness is considered high and is attributed to a high carbon amount along with molybdenum and manganese elements in the composition.

Properties

- High Toughness: With the maximum hardness level of 62 HRC, this steel is considered hard. So, as the hardness is high, you may think that its toughness level will be low. However, this is not true. Surprisingly, A2 provides great toughness! It is tougher than D2. This means that A2 steel knives would hardly break, crack, or chip despite frequent heavy-duty use. The credit goes to the nickel and vanadium content. Due to a high toughness level, this Crucible steel has been the first choice for die steel. For this reason, it is also preferred for making knives meant for tough use.

- Excellent Edge Retention: This carbon steel is admired for keeping a sharp edge for a long time. This is because A2 has more chromium carbides. Its ability to hold an edge is close to that of 440C.

- Medium Wear Resistance: Although A2 has a high level of hardness, its wear resistance power is not that high. In this case, you enjoy a high toughness level at the cost of wear resistance. This does not mean that A2 has poor wear resistance. What it means is that you can expect moderate resistance to wear as well as abrasion. When it comes to wear resistance, this steel sits in between the O1 and D2 tool steels.

- Low Corrosion Resistance: Due to the low chromium amount, A2 steel has poor corrosion resistance. Still, its anti-corrosion performance is admirable than that of most carbon steels. Just clean it and keep it dry after you use it every time so that no moisture remains to invite rust. You also need to lubricate the blade for ensuring a protective layer while in storage.

- Ease of Sharpening: Despite having a high hardness level and great edge holding ability, A2 is very easy to sharpen. The reason is that it contains relatively low chromium carbides, hence the wear resistance is low. This facilitates not only effortless polishing and grinding but also quick sharpening.

Comparison With Other Knife Steel Options

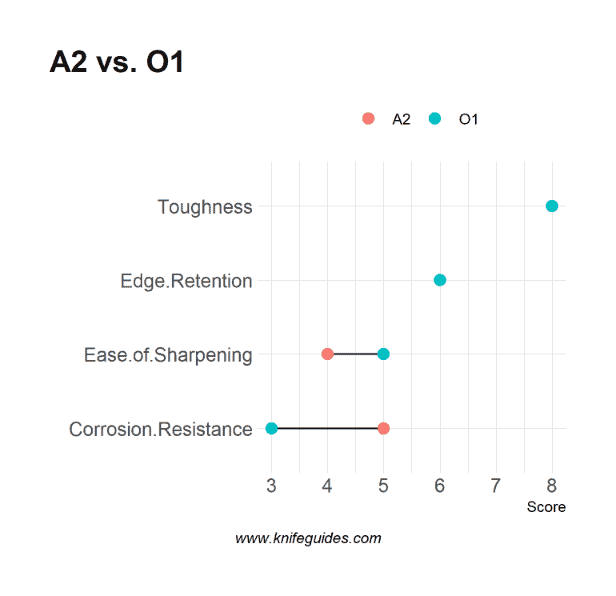

A2 vs O1

O1 is known to take a sharper edge, but the sharpness fades faster than A2. Thus, O1 needs more frequent sharpening. A2 wins over O1 with better resistance to wear and corrosion.

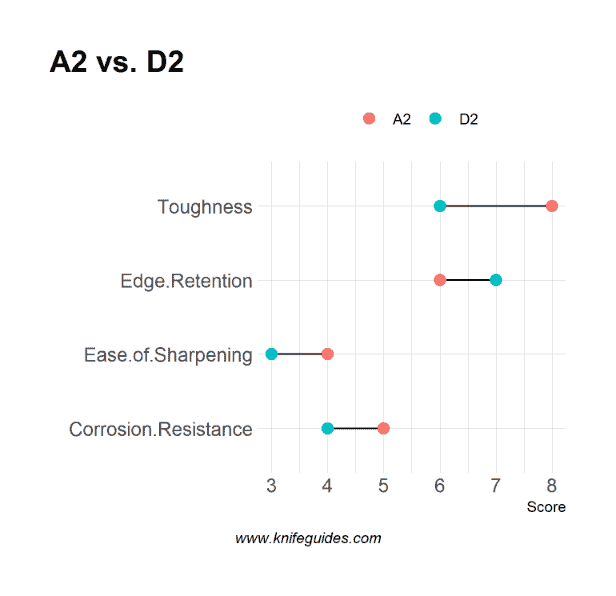

A2 vs D2

A2 wins over D2 in terms of toughness, ease of sharpness, and corrosion resistance. D2 wins in edge retention though.

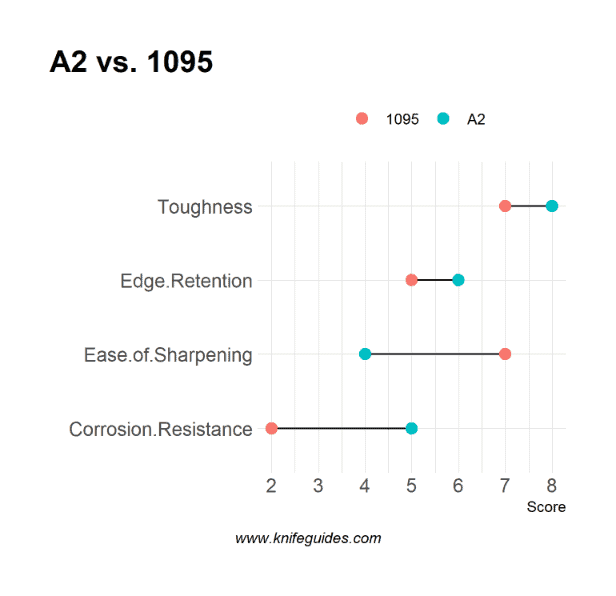

A2 vs 1095

A2 wins the competition in terms of toughness, edge retention, and stain resistance. On the other hand, sharpening 1095 is far easier.

Top A2 Knives on Amazon

| Image | Title | Price | Buy |

|---|---|---|---|

| Boker Plus A2 42 Folding Knife | Check Price on Amazon | |

| TACZEBRA Full Tang Tactical Hunting Knives | Check Price on Amazon | |

| L.T. Wright Handcrafted Knives Genesis | Check Price on Amazon | |

| Hogue 35109 EX-F01 | Check Price on Amazon |

So, is A2 a Good Knife Steel?

Yes! A2 is a good knife steel, because of its ideal balance of hardness and toughness, ensuring great edge retention and medium wear resistance. Despite its high hardness, A2 is easy to sharpen. However, you need to take proper care of this knife to keep the rust away.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.