(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

If you are knife-savvy, you know Japanese steel grades, known for their unbelievable toughness, edge quality, and sharpness. If so, it is impossible not to come across the AUS-8 (8A) steel. It allures those who want a novel, fairly-priced model to be added to the collection of knives.

However, does it offer high performance as other Japanese steel? Is it a better option compared to non-Japanese counterparts? Let’s find out in this AUS 8 steel review!

What is AUS-8 Steel?

AUS 8 is a popular Japanese steel admired for its mid-range performance. Built by Aichi Techno Fukami, it belongs to the family of stainless steel. It is one of the best sellers in the AUS series.

Many knife fans and experts associate this steel with 440C, the stainless-steel standard, and other highly-rated grades in the category, such as D2 and 154 CM. Thus, expectations from the AUS 8 stainless steel are high. After all, it is alleged to be one of the superior stainless-steel grades, which can fulfill all standards to ensure high-quality blades.

Apart from creating knives, this steel is used for making scissors, automotive parts, medical devices, and the parts of food machines.

Chemical Composition

This stainless steel contains a higher level of carbon. Thus, it belongs to the category of mid-range steels. There are also other components such as vanadium, nickel, and molybdenum. Hence, some may feel it is close to many premium steel options. Following are the different components of this highly refined steel:

- 0.75% Carbon: For improved resistance to wear and corrosion as well as increased hardness level

- 14% Chromium: For high tensile strength, toughness, hardness, edge retention, and corrosion and wear resistance

- 1% Silicon: For higher strength

- 0.5% Manganese: For more resistance to wear, hardenability, and forgeability

- 0.5% Nickel: For more toughness

- 0.3% Molybdenum: For better hardenability, strength, and toughness

- 0.25% Vanadium: For more strength, toughness, and resistance to wear and corrosion

- 0.04% Phosphorus: For more strength

- 0.02% Sulfur: For enhanced machinability

Steel Hardness

On the Rockwell scale of hardness, the AUS 8 steel has a rating of 59 HRC, although it can be 58 HRC as well. The exact rating depends on the kind of heat treatment the manufacturer has given.

Steel Properties

The chemical composition of AUS-8 indicates which properties are truly commendable. Let’s explore them!

- Okay Toughness: This Japanese steel is fairly tough due to the presence of nickel and the high content of chromium. This steel can withstand heavy impact and heavy use without chipping or breaking easily. With an apt heat treatment, an AUS 8 knife becomes tougher.

- Great Corrosion Resistance: Due to the chromium content exceeding 12%, AUS 8 exceeds the least threshold required for a steel to be a part of the stainless family. Thus, it can easily resist corrosion and rusting even if exposed to humidity and saltwater.

- Great Wear Resistance: This is another great property of this stainless steel. Due to the inclusion of molybdenum, manganese, and silicon, you can expect excellent anti-wear performance from this steel. This is the reason why it can withstand well without losing its form as well as sharpness. This steel can even keep abrasive damage at bay, which may be why it is often compared to the premium grades.

- Good Edge Retention: An AUS8 steel edge will retain its sharp edge well even with heavy use. The credit goes to the steel’s high carbon content and apt hardness level. In this area, AUS 8 is often contrasted with premium steels. Because of this property, this steel is widely used for making cutting tools.

- Ease of Sharpness: You can easily obtain a razor-sharp edge on an AUS 8 blade without much effort. This is due to the good balance of hardness and toughness. It is not that time-consuming or complicated to sharpen this steel. You can expect to get highly sharp portions at finer edges.

Comparison With Other Knife Steel Options

Just knowing the structural components and properties, you truly cannot make out how well the AUS-8 steel can perform. You also need to compare its properties to other competitive counterparts.

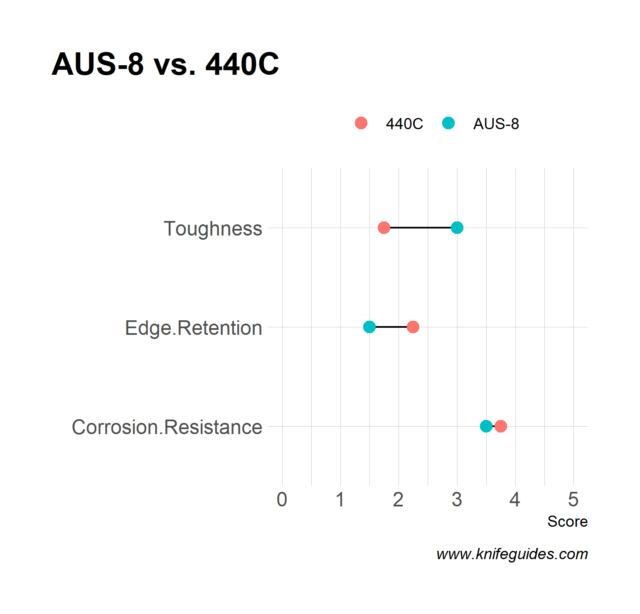

AUS 8 vs. 440C

440C is harder and better at edge retention. Hence, it is easier to sharpen an AUS-8 edge than 440C. 440C is slightly more resistant to corrosion as well.

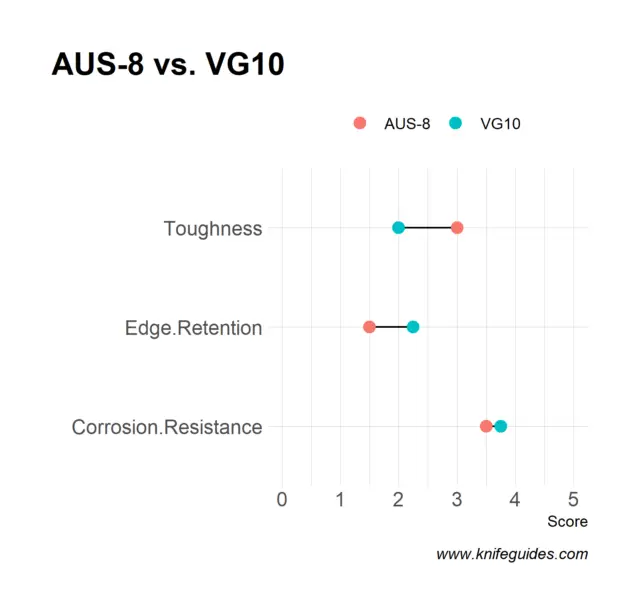

AUS 8 vs. VG10

Both the steels come from Japan. However, VG10 ensures better edge retention and corrosion resistance than AUS-8. On the other hand, it is not that easy to sharpen a VG10 edge on the flip side. Moreover, VG10 is expensive as well.

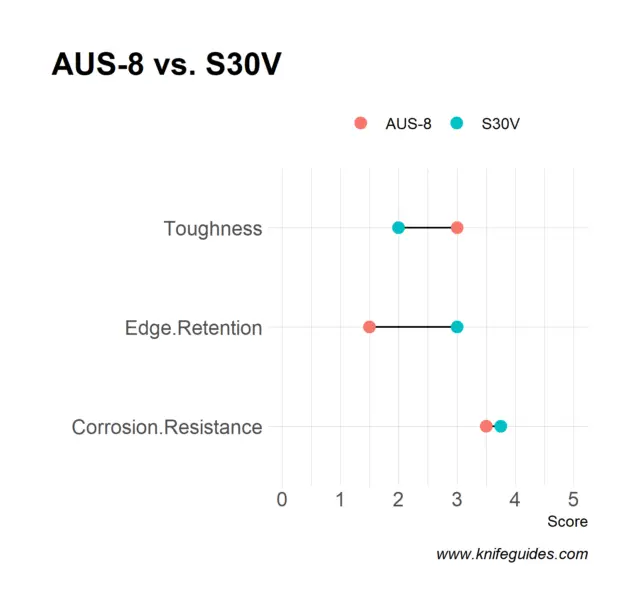

AUS 8 vs. S30V

S30V comes with better resistance to wear and a higher hardness level than AUS-8. So, S30V knives usually last longer. Nevertheless, sharpening an S30V edge is more challenging. But, in terms of corrosion resistance, both are close.

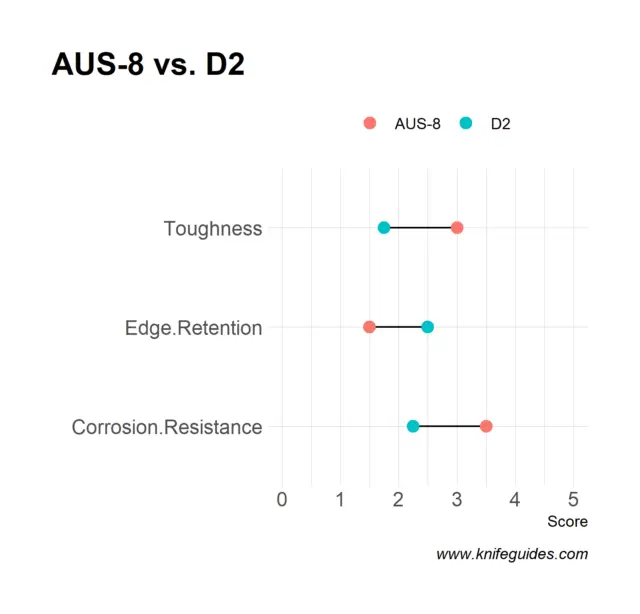

AUS 8 vs. D2

D2 is semi-stainless, hence performs worse than AUS 8 in terms of corrosion resistance. However, AUS-8 is easier to sharpen, while D2 is harder and holds its edge better.

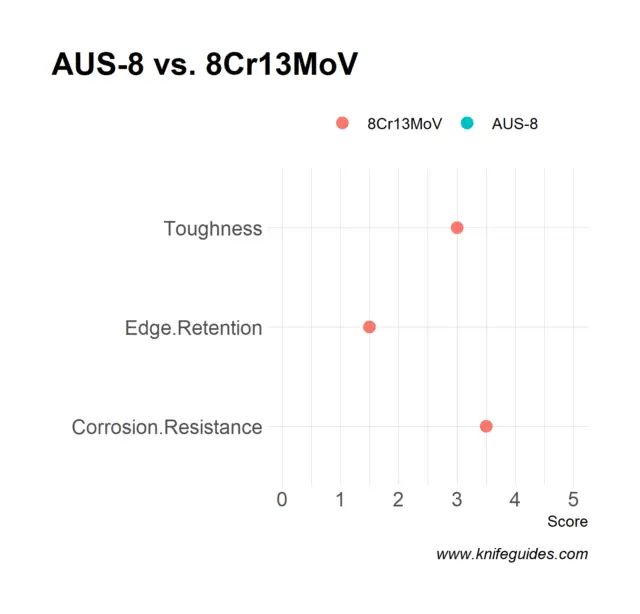

AUS 8 vs. 8Cr13MoV

Both steels perform similarly in all aspects. The 8Cr13MoV steel in China is made similar to the AUS-8 steel in Japan.

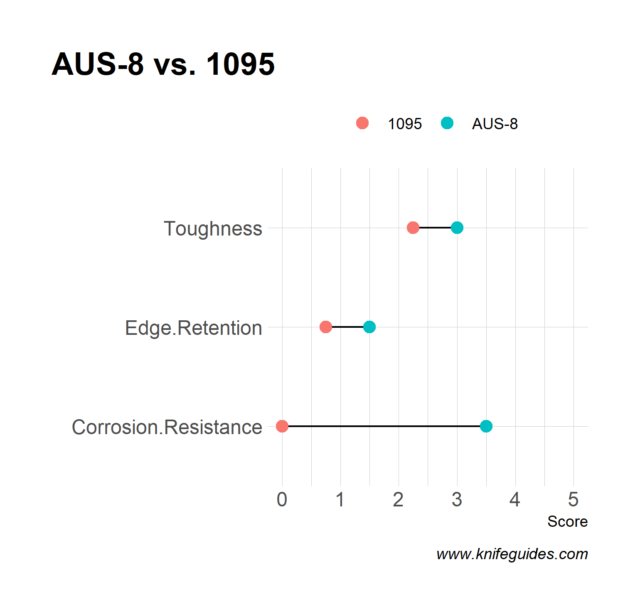

AUS 8 vs. 1095

AUS 8 is harder; hence is better at edge retention. It is also tougher. 1095 is the worst in corrosion resistance; hence no need for further comparison.

So, is AUS-8 Steel Good?

Yes, it is if you are looking for mid-level material for your knives. AUS-8 can be an excellent option for your knife due to its price, good balance of toughness and hardness, good edge retention, and resistance to wear and corrosion. In addition, if you are a knifemaker, you will like the machinability of this steel.

Although not a premier-tier steel grade, AUS 8 stainless steel delivers fair value for its price range. As it is a mid-range steel option, it is essential to take care of the blade by oiling it whenever required. If this is ensured, you can rely on this quality steel blade for a long time.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.