(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

If you have gone through some popular knives, chances are high for you to spot Sandvik 14C28N steel. It is among the steel options of the highest value for money, as it accomplishes hardness without squeezing the integrity of its microstructure. The Sandvik steel is used by all upscale knife makers and even custom knife makers. In this post, let’s find out how good this steel option can be for your knives.

What is Sandvik 14C28N Steel?

14C28N is a type of stainless steel manufactured by the Sandvik group, a Swedish brand. Knife fans across the globe admire this brand for its high-quality metallic items. Its 14C28N steel is referred to as non-powder metal explicitly made for knife blades.

The steep option was born due to the initiative of Sandvik’s engineers to come up with an upgrade of 13C26, a type of stainless steel used for making shaving razors. They wanted this upgraded version to be more resistant to corrosion. For this purpose, more chromium was utilized to make this steel.

Unlike most steels that have carbon for increasing hardness, this one uses nitrogen for the same and for discarding rusting and corrosion.

Composition

The 14C28N Sandvik steel contains a high amount of chromium. It has the highest percentage of the total composition, due to which this material qualifies as stainless steel. The second most profuse ingredient is carbon. This composition sets this steel apart from other types of steel. It was incorporated with just one goal, resistance to rust and corrosion. Following are the various elements of which this steel is made up of:

- 14% chromium for better edge retention, tensile strength, corrosion resistance, and wear resistance

- 0.62% carbon for better hardness and resistance to wear and corrosion

- 0.6% manganese for enhanced brittleness and hardness.

- 0.2% silicon for more strength

- 0.11% nitrogen for more strength and better edge retention

- 0.025% phosphorus for more strength

- 0.01% sulfur for better manufacturing

Hardness

The hardness level of 14C28N relies significantly on the manufacturing process, especially its heat treatment. Usually, the HRC rating ranges from 55 to 62. However, most knives for kitchen use have a hardness rating between 52 and 60, whereas it is between 57 and 59 for everyday pocket knives.

However, the hardness range of the steel makes it quite versatile. You can find different types of knives made using this steel.

Properties

- Below average hardness: Comparing its hardness range against other stainless steel, we can say that it is not hard.

- Excellent corrosion and rust resistance: This is not surprising due to the high chromium content – over 10%. This is why this steel is used to make knives that can last long in humid and wet environments.

- Average edge retention: This steel is less hard than most stainless steel due to the high percentage of carbon and chromium. As a result, it can’t deliver decent edge retention.

- Average Wear Resistance: The inclusion of manganese contributes to decent wear resistance.

- Excellent Toughness: This steel is very tough. Although the point may blunt a bit, it will not chip or roll whether you stab something or hammer it.

Comparison with Other Knife Steel Options

The comparison is based on ease of sharpness, corrosion resistance, toughness, and edge retention. So let’s compare and see how this steel fares.

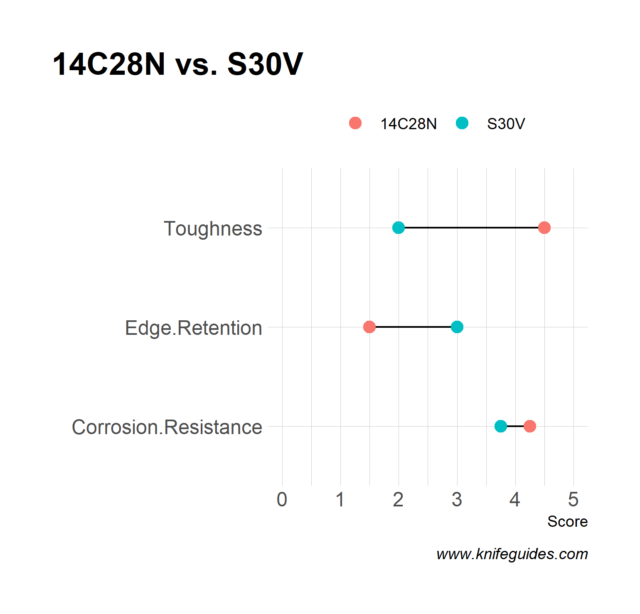

Sandvik 14C28N vs. S30V

The latter wins in terms of edge retention & corrosion resistance, and the former wins in sharpening ease and toughness.

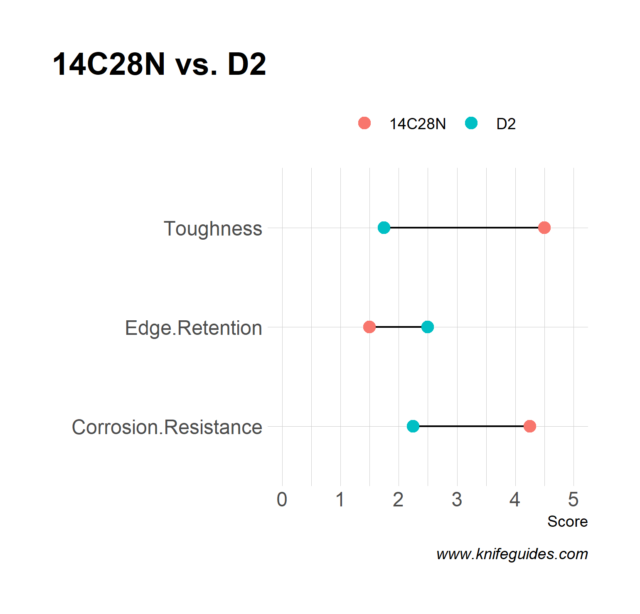

14C28N vs. D2

D2 has a better edge retention ability. 14C28N is easier to sharpen. Both have the same level of toughness and corrosion resistance.

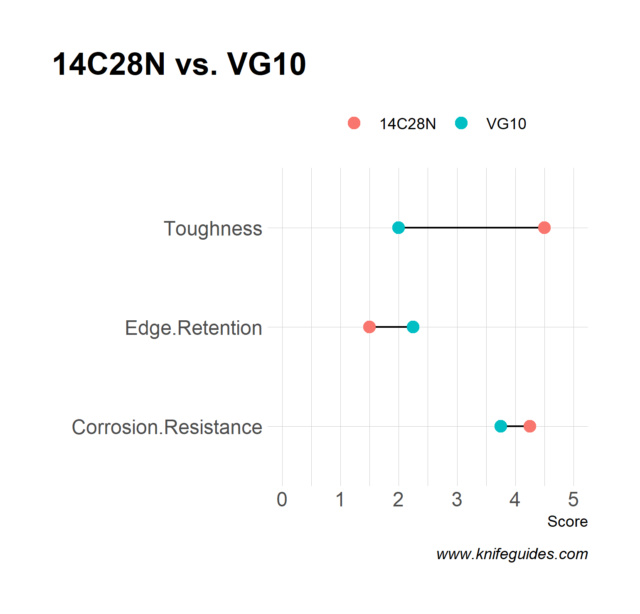

14C28N vs. VG-10

VG-10 has a better ability to retain the edge and corrosion resistance but lower toughness than the former. However, the ease of sharpness is the same for both.

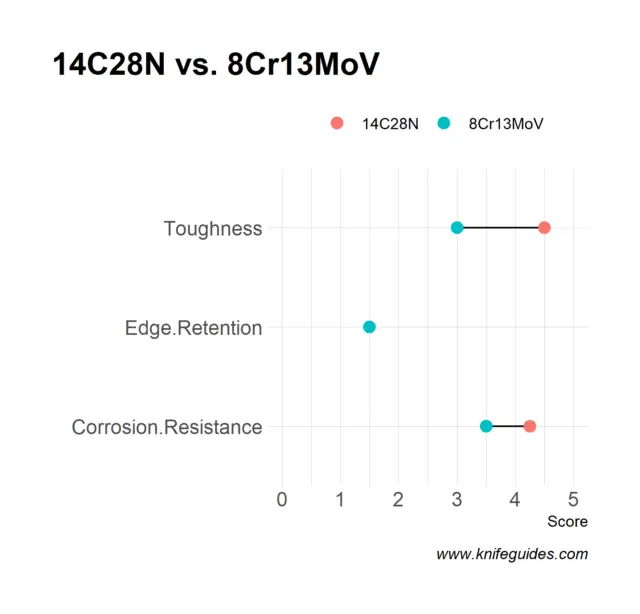

Sandvik 14C28N vs. 8Cr13MoV

The latter has lower resistance to corrosion and the ability to retain the edge than the former. Although toughness is the same, it is easier to sharpen the 8Cr13MoV blade.

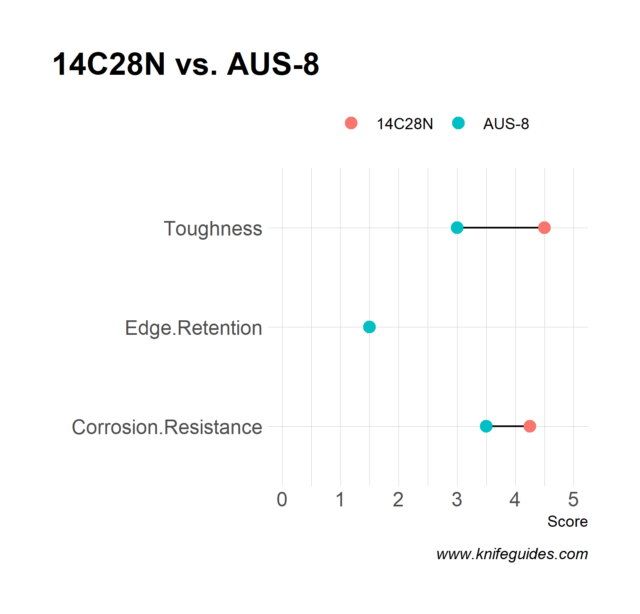

14C28N vs. AUS 8

The former retains the edge better. However, you can sharpen an AUS 8 blade quicker.

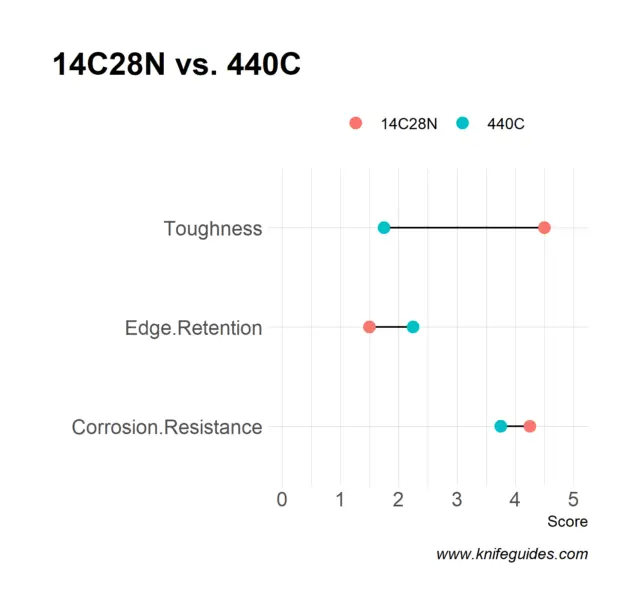

14C28N vs. 440C

The former is better at corrosion resistance. Both are relatively easy to sharpen and retain the edge almost the same.

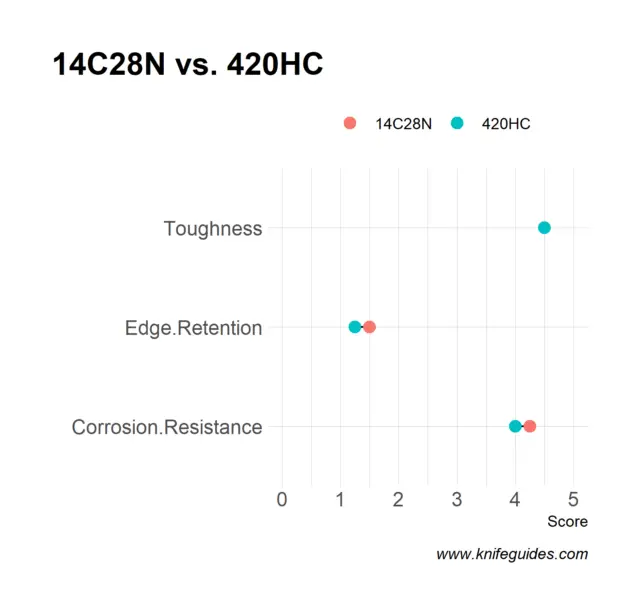

14C28N vs. 420HC

The latter has a bit lower resistance to corrosion and edge retention than 14C28N. However, it is easier to sharpen than the latter.

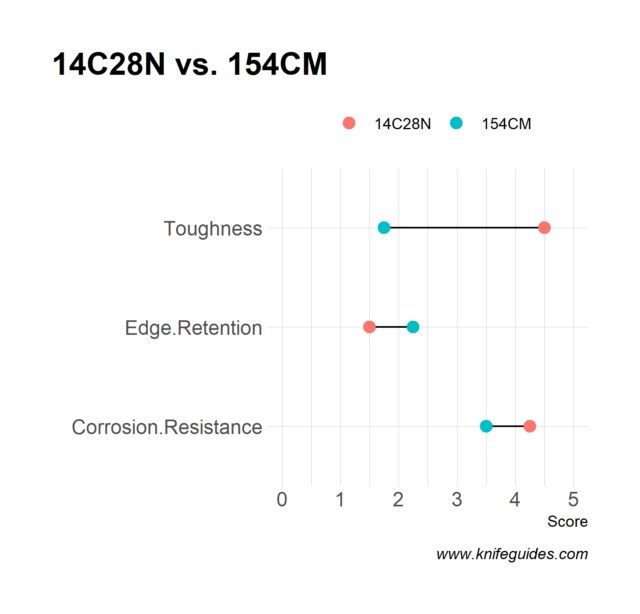

14C28N vs 154CM

154CM excels in hardness and thus in edge retention but fares worse than 14C28N in toughness, corrosion resistance, and ease of sharpening.

So, is 14C28N steel Good for Your Knives?

Sandvik 14C28N has high toughness, above average corrosion resistance, and decent edge retention. It is a very affordable stainless steel variant and is considered the best budget steel for knives.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.