(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

You may have come across a 420HC blade if you are after budget-friendly knives from Bucks or Gerber. These two esteemed brands widely use this steel to make a distinct collection of affordable knives with decent performance.

What is 420HC Steel?

420HC refers to the advanced version of the 420 steel. It is a low-end martensitic steel made by Latrobe in the United States. It is widely used for making cutlery, scissors, custom knives, and surgical tools. It is used to make various knives such as camping, tactical, EDC, and even machetes. 420HC evolved by modifying 420 by adding more carbon content. Thus, the letters HC in the name represents ‘High Carbon.’

There are several types of steels, of which a specific set is termed 420 steels. In this category, the HC version is usually tagged as the best of them. This is because of its high carbon content.

However, it is a fact that many other steels have even higher carbon content. Many people believe that the carbon amount in this steel is just right. The steel is significantly affordable. Therefore, these knives usually cost below fifty bucks.

Just because this steel is affordable does not mean that its performance is not up to par. It is widely used for making affordable Kershaw, Buck, and Gerber knives.

Chemical Composition

420HC is a type of stainless steel(>11% Chromium). There is also enough carbon as well as vanadium. Following are the various elements of which this steel is made up:

- 13% chromium for better tensile strength, resistance to corrosion as well as wear, and retention of sharpness

- 0.46% carbon for enhanced hardness, durability, as well as resistance to wear and corrosion

- 0.4% manganese for improved hardness and sharpness retention

- 0.4% silicon for better strength

- 0.3% vanadium for better hardenability as well as wear resistance

Steel Hardness

Generally, the hardness level of 420HC stainless steel is around 55 HRC. Although many other steel versions are harder, this is sufficiently hard for most tasks. However, a few knife manufacturers apply their distinct heat treatment process; hence the hardness can go up in the range of 56 to 59 HRC.

420HC Stainless Steel Properties

The chemical composition of this steel indicates its properties. Following are its most significant properties that you can expect:

- Decent Edge Retention: It is a fact that many newer steel variants hold a sharp edge for a time longer than that of 420 HC. Practically, the ability to retain a sharp edge of 420 HC steel is not that bad. However, this steel can retain a sharp cutting edge longer than other variants in the 400 series. So, although you may have to sharpen your blade quite often, it would not be as often as in the case of any other 400 option.

- Great Corrosion Resistance: 420 HC is a pure type of stainless steel, as it has the required amount of chromium content. Thus, it fully keeps rust and corrosion at bay. As a result, wet conditions are no longer a problem for your knife. Further, if you keep wiping your blade after using it, you may not even face the issue of discoloration after many years of use.

- Good Sharpening Ease: It is one of the easiest steel variants to sharpen. After all, only a handful of steel variants are easy to sharpen.

- Toughness: This steel is tough, although its hardness level can be more if heat-treated distinctively. Toughness refers to the ability to resist chipping. This steel will not chip quicker than other steels in the 440 series. As a result, this steel can endure a fair amount of abuse.

Comparison With Other Knife Steel Options

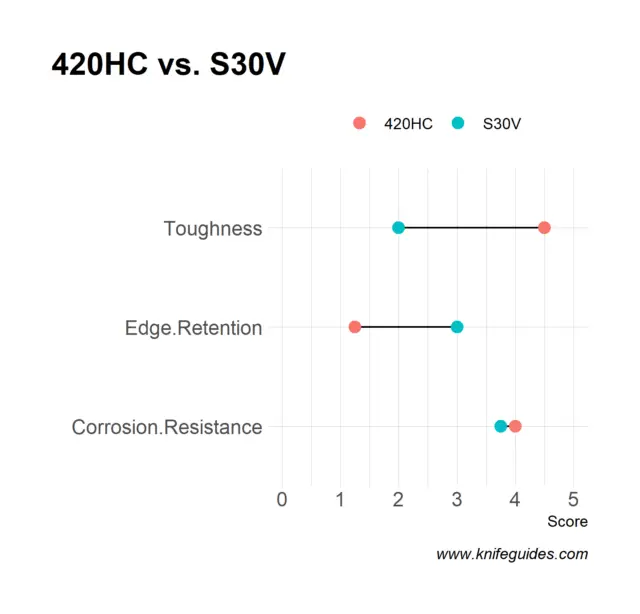

420HC vs. S30V

S30V is a premium steel variant that is pricier than lower mid-range steels like 420HC. In terms of edge retention and corrosion resistance, S30V wins the race. Still, the HC steel competes closely with S30V in terms of resisting corrosion. However, it loses significantly to S30V when it comes to edge retention. In terms of ease of sharpness and toughness, 420 HC scores better.

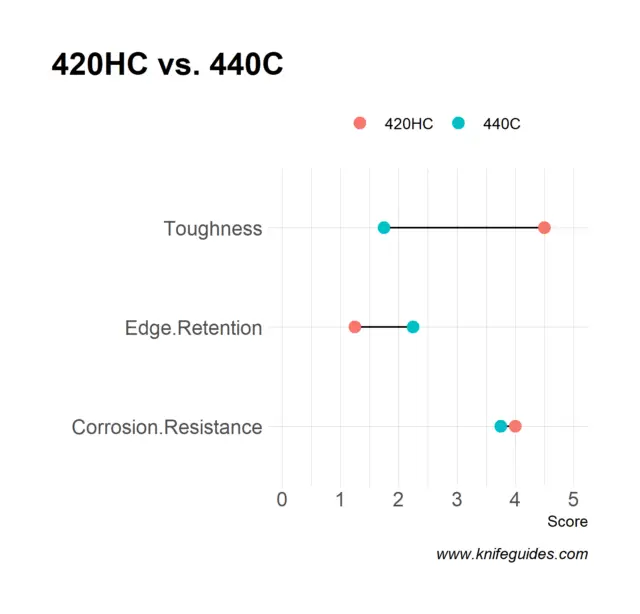

420HC vs. 440C

The pricier 440C steel is harder than 420 HC but is relatively less tough. This means its ability to hold a sharp edge is better and is also more resistant to corrosion. While both are easy to sharpen, the HC blade is easier to sharpen than 440C.

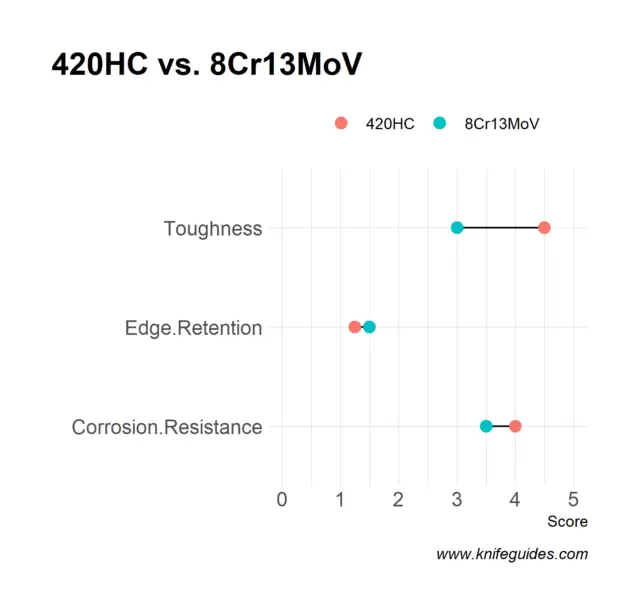

420HC vs. 8Cr13MoV

Just as 440C, 8Cr13MoV is an upper mid-range option. However, in terms of edge retention and resistance to corrosion, both score almost the same. 420HC is more rustproof than 8Cr13MoV. In terms of toughness, 8Cr13MoV is far behind.

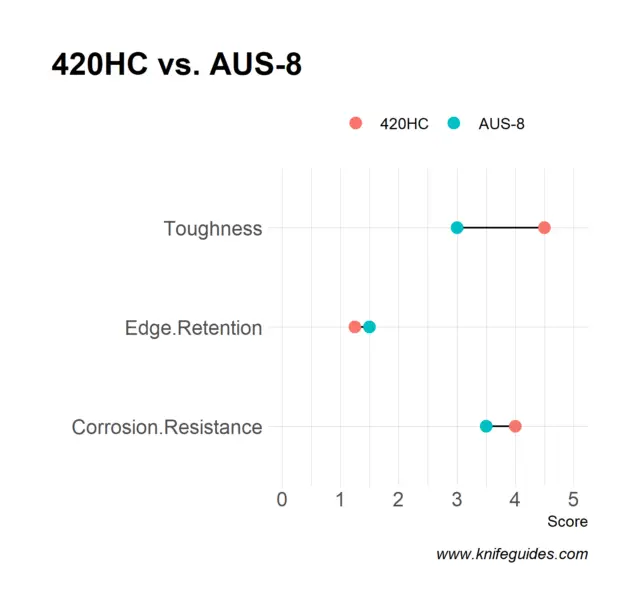

420HC vs. AUS 8

The latter is another upper mid-range option, just as 8Cr13MoV. In terms of edge retention and toughness, both steels score the same. However, when it comes to resisting corrosion, AUS 8 is better. In addition, AUS 8 steel is a bit easier to sharpen than the 420HC steel.

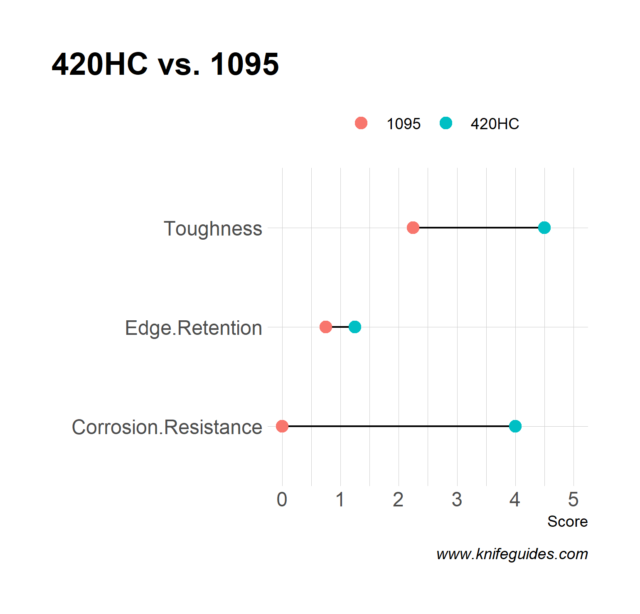

420HC vs. 1095

The latter is lower mid-range steel, as well. While both are easy to sharpen options, they differ significantly. In terms of edge retention, 420HC gets a slight edge. However, when it is the matter of resisting rust and corrosion, the former is significantly better than 1095, which rusts easily if used in a humid setup.

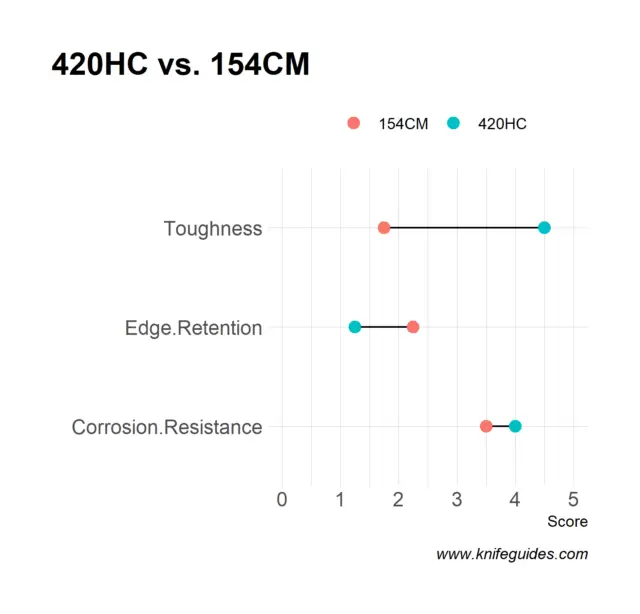

420HC vs. 154CM

The latter is one of the high-end steel variants. It is considered all-around steel but is only on par with the former when keeping rust or corrosion at bay. However, 420HC is less likely to rust. On the other hand, the ability of 154CM steel to retain a sharp edge is much better. However, the former wins over 154CM in terms of ease of sharpness and toughness.

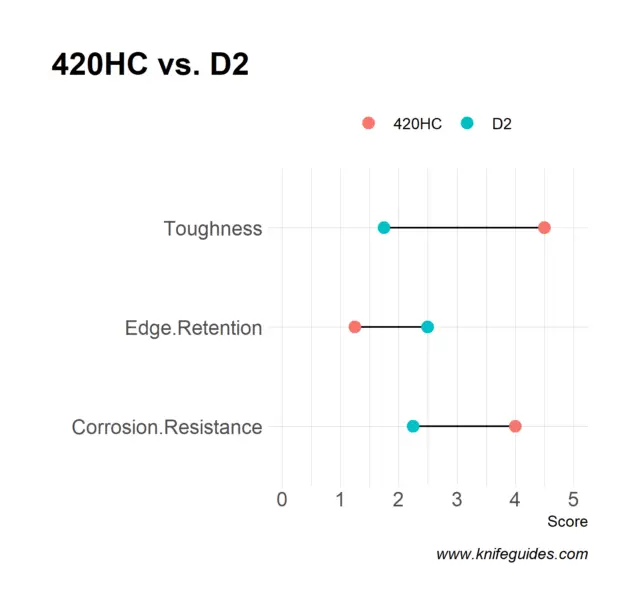

420HC vs. D2

D2 is harder and much better at edge retention. In terms of toughness and corrosion resistance, 420HC wins.

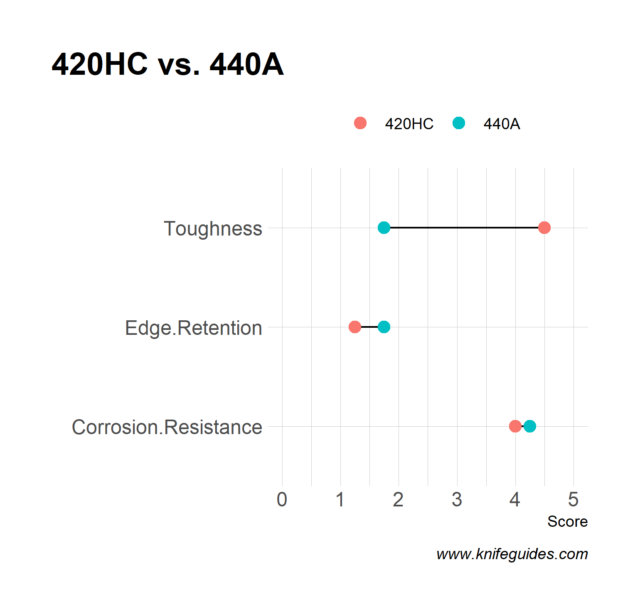

420HC vs. 440A

440A is slightly better at corrosion resistance and edge retention. In terms of toughness, 420HC wins by a huge margin.

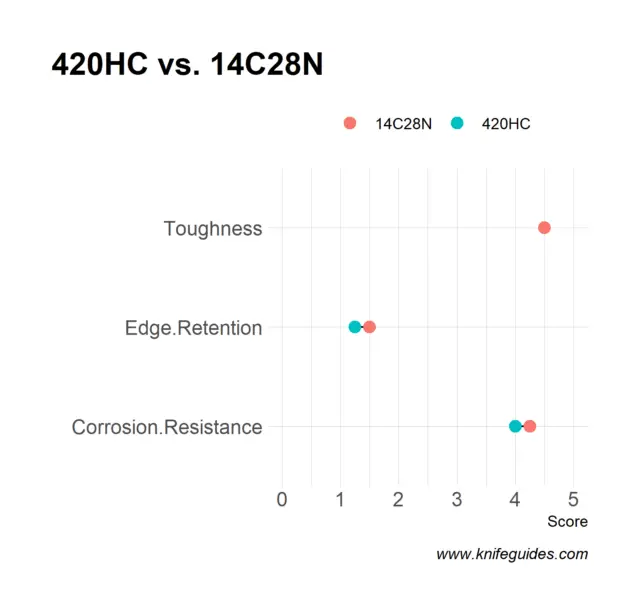

420HC vs. Sandvik 14C28N

The Swedish steel is very close to the 420HC in all aspects.

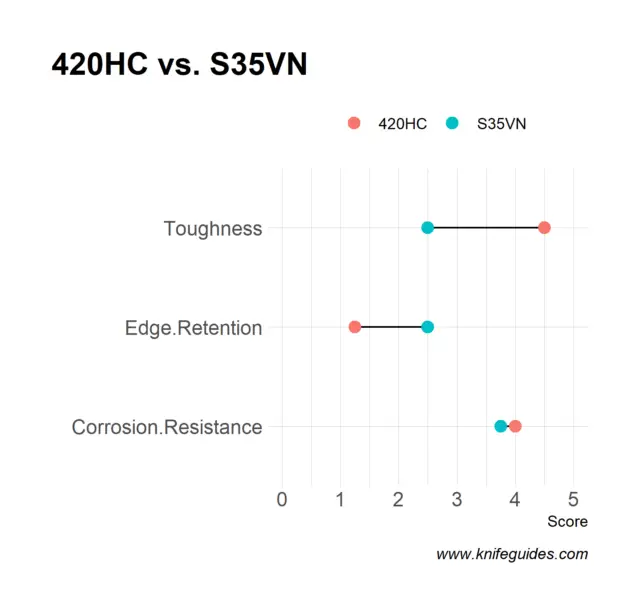

420HC vs. S35VN

S35VN is a premium steel, which is expensive and harder. However, it is much better at edge retention has similar corrosion resistance to 420HC.

So, is 420HC a Good Knife Steel?

420 HC is an ideal option for making low-entry knives. Due to its good corrosion resistance power, decent edge retention ability, and ease of sharpening, this is good economical steel for knives. However, due to poor resistance to wear, you need to take proper care of your knife.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.