(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Let’s acknowledge it: CPM S35VN steel pocket knives are among the finest knives available in the market today. Venerated makers such as Zero Tolerance, Bark River, Spyderco, Benchmade, Boker, and Hinderer use this high-end steel in making the blades of their knives. Even Chris Reeve uses it!. In this post, let’s explore why it is a popular steel for high-end knives.

What is CPM S35VN Steel?

CPM S35VN is a martensitic steel made by Crucible Industries based in the United States. It belongs to the SxxV series and is made using the brand’s proprietary Crucible Particle Metal (CPM) methodology. In the name, the S, V, and N letters stand for Stainless, Vanadium, and Niobium, respectively. The number 35 has no significant interpretation and is added to differentiate from its predecessor, S30V.

CPM S35VN is a relatively new grade. It was first formulated in 2009 to improve its former top steel, CPM S30V. The goal of Crucible was to come up with a tougher grade than S30V without compromising corrosion resistance.

For this, the brand replaced some of the vanadium carbides with niobium carbides. Carbides are hard bits of carbon alloys in the material matrix and determine edge retention as well as toughness, although they can be brittle if used in incorrect combinations.

This upgrade became possible with the help of Chris Reeve, an iconic South African-American knifemaker who had also contributed to the making of S30V. CPM S35VN is an all-around premium steel with the required balance of all the important properties but without any weaknesses or limitations.

It is used in making a myriad of knives such as EDC and tactical knives. It is also used for making small parts of machinery, ball bearings, and specialty cutlery.

Chemical Composition

CPM S35VN has enough chromium to make it stainless. Below are the components that make up this high-end steel:

- 1.4% Carbon: For boosted hardness as well as resistance to wear as well as corrosion

- 14% Chromium: For boosted edge retention, tensile strength, and resistance to corrosion and wear

- 3% Vanadium: For boosted hardenability as well as wear resistance

- 2% Molybdenum: For boosted strength as well as machinability

- 0.5% Niobium: For boosted hardness as well as resistance to wear and corrosion

Hardness

On the Rockwell scale, the hardness rating of S35VN ranges from 57 to 64 HRC. The exact rating depends on the type of heat treatment to which the blade is subjected. This range indicates that this steel can get very hard. This high range assures excellent durability, hence suitable for daily use in tough situations.

The credit for this goes to the inclusion of vanadium, molybdenum, and niobium. The presence of niobium results in tiny but super-hard carbides that are harder than vanadium carbides.

Steel Properties

- Decent Toughness: Hard steels are not expected to be tough, and are usually prone to chipping upon impact. However, CPM S35VN steel is tough enough. S30V, its predecessor, is already tough. With the inclusion of niobium along with the finer grain structure and the CPM process, the toughness level of CPM S35VN has been improved. After all, the motive to introduce this steel was to have a steel grade that is tougher than S30V. This steel is more resistant to breaking, cracking, and chipping under lateral pressure.

- Good Corrosion Resistance: As this steel is stainless due to its high chromium level, you can expect it to keep stains and rust at bay even in saltwater conditions. Still, it is not as good as what you can expect from Elmax or M390. It is essential to maintain your knife by cleaning and drying it after use.

- Excellent Edge Retention: You can expect this steel to retain an ultra-sharp edge for a long time. The credit goes to the high vanadium and niobium content. The hard niobium carbides increase its edge holding capability.

- Great Wear Resistance: This is expected due to a high level of hardness. Niobium with carbon results in niobium carbides that make this steel very effective in resisting wear. Even the high vanadium content helps in keeping wear at bay. Further, molybdenum also interacts with carbon to result in hard carbides, which eventually contribute to hardness and wear resistance. You can expect commendable abrasion resistance and consistent performance lasting for years without deformation.

- Ease of Sharpening: As this steel is very hard, it is not easy to sharpen it. Still, it is not that challenging to sharpen this steel edge compared to harder grades.

Comparison With Other Knife Steel Options

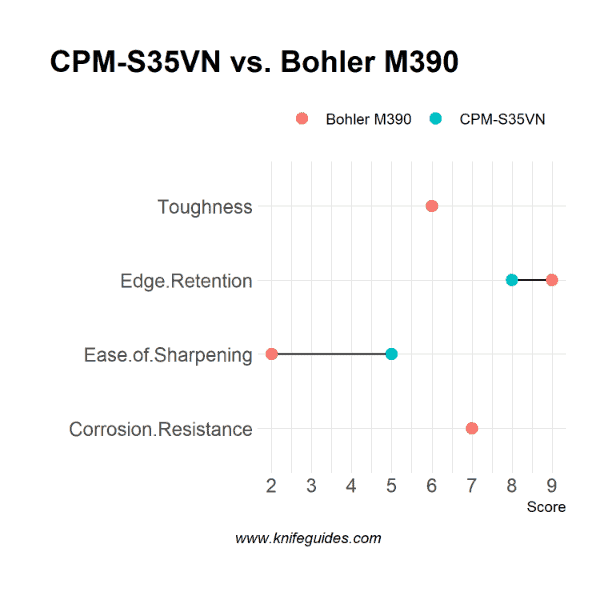

CPM S35VN vs M390

Although less popular than S35VN, M390 is higher in the ranks of steel grades. It is better at edge retention but difficult to sharpen.

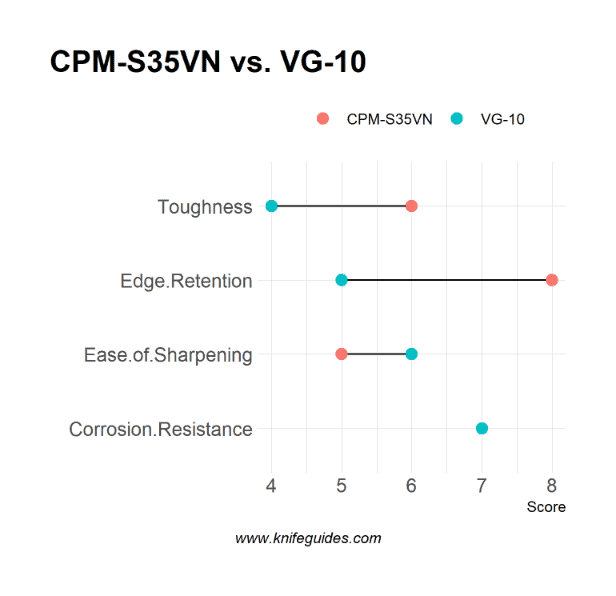

CPM S35VN vs VG10

S35VN wins over VG10 in terms of edge retention and toughness. However, VG10 is easier to sharpen. Both steels rank the same for corrosion resistance.

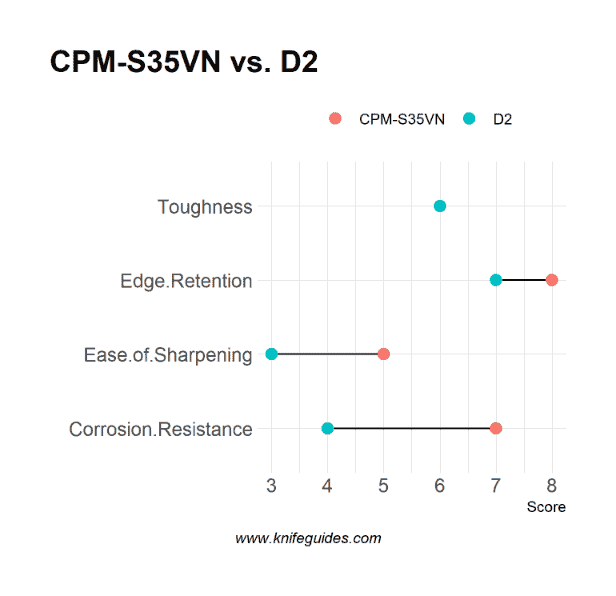

CPM S35VN vs D2

S35VN outperforms the D2 steel in terms of edge retention and corrosion resistance. While both have almost the same level of toughness, sharpening the CPM steel is easier than D2 as well.

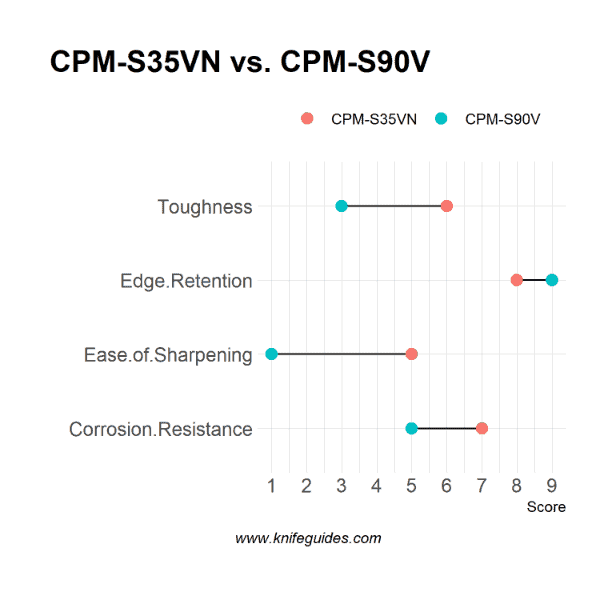

CPM S35VN vs S90V

When it comes to edge retention, S90V wins over S35VN. On the other hand, S35VN is better at the ease of sharpening, toughness, and corrosion resistance.

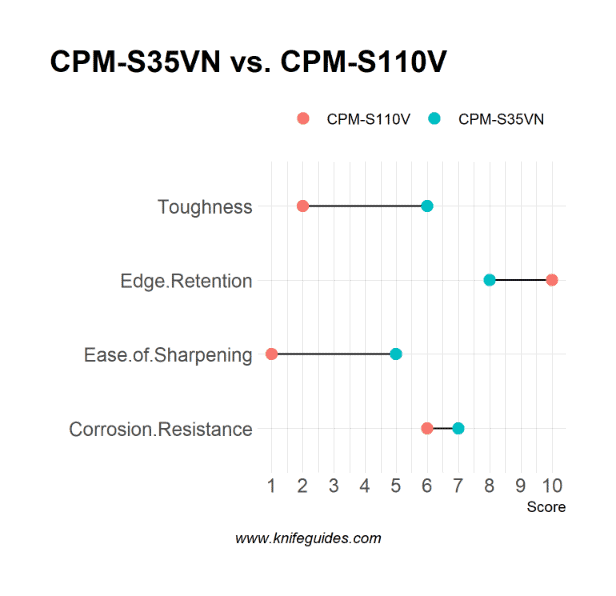

CPM S35VN vs S110V

Both steels are great performers. However, S110V is harder, more wear-resistant, and holds its edge longer. On the other hand, S35VN is tougher and easier to sharpen than S110V.

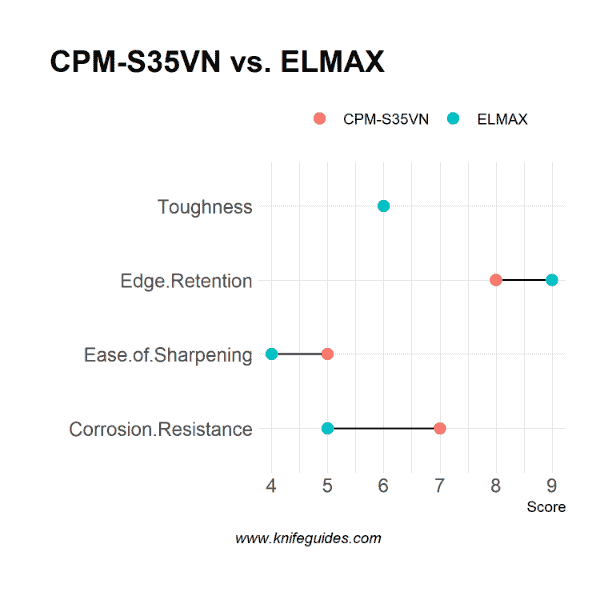

CPM S35VN vs Elmax

Belonging to the premium steels, Elmax wins over the CPM steel in terms of hardness, wear resistance, and edge retention. Of all super steels, Elmax is the easiest one to sharpen, but it is still challenging.

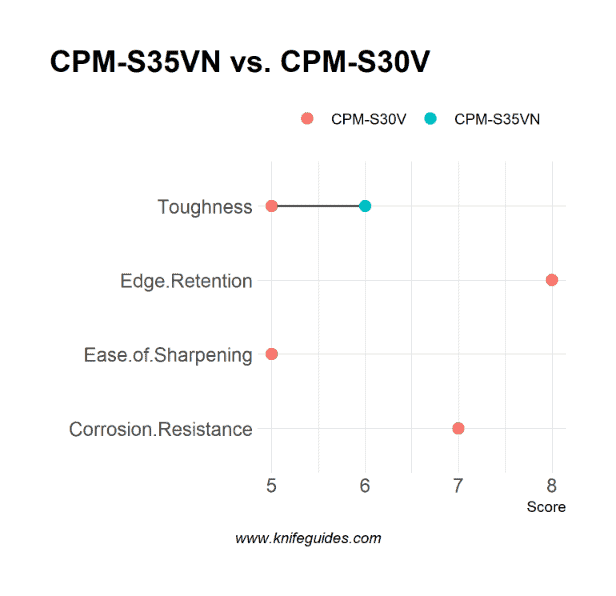

CPM S35VN vs S30V

S35VN is tougher than S30V. Both perform similarly in all other parameters.

Top 5 CPM-S35VN Knives on Amazon

| Image | Title | Price | Buy |

|---|---|---|---|

| DROP + Ferrum Forge Gent | Check Price on Amazon | |

| SOG KU-3004 Kiku | Check Price on Amazon | ||

| Zero Tolerance 0450CF | Check Price on Amazon | |

| Pro-Tech SBR Fixed Blade Knife | Check Price on Amazon | |

| Buck Knives 112 Ranger Slim Pro Plus | Check Price on Amazon |

So, is CPM S35VN a Good Knife Steel?

Yes, CPM S35VN steel is a great option for knives. It excels in retaining an ultra-sharp edge for long, ensuring great wear resistance, and maintaining a high toughness level. On the flip side, it is costly and difficult to sharpen.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.