(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

M390 is one of the strongest steel available for modern knife blades. It belongs to the premium steel category and is known as the best all-around steel for making high-end knives. In this post, let’s find out whether this super steel is worth the price tag it comes with.

What is M390 Steel?

M390 is an ultra-premium or super steel formulated by Bohler-Uddeholm (combination of Bohler from Austria and Uddeholm from Sweden). It is a type of martensitic stainless steel having high vanadium and high chromium and is made using the third-generation Powder Metallurgy (PM) technology to ensure additional resistance to corrosion and wear.

Bohler tags M390 as micro-clean. This is because it features a super-fine structure of grain size and is capable of having a mirror finish to render a cool look.

Technically, M390 is a tool steel. Just as any other super steel, it was specifically made for hard use amidst the risk of tear and wear. Another purpose of introducing it was to ensure high resistance to shocks and vibration, justifying why this steel is widely used in making industrial tools such as barrels, screws, and injection molding.

M390 steel is considered ideal for designing small fixed or folding knives. As it is very expensive, it is usually used for making limited edition and high-end knives.

Chemical Composition

The super steel is stainless steel because of >13% chromium content. Following are the elements of this stainless steel:

- 1.9% Carbon: For improved hardness and a higher ability to keep wear and corrosion at bay than expected

- 20% Chromium: For boosted edge retention, hardness, toughness, tensile strength, and resistance to corrosion and wear

- 4%: Vanadium: For hardenability, toughness, and improved resistance to shock loading

- 1% Molybdenum: For improved strength and better machinability

- 0.6% Tungsten: For improved toughness as well as strength

- 0.7% Silicon: For improved strength

- 0.3% Manganese: For improved tensile strength, forgeability, hardenability, and resistance to wear

Steel Hardness

According to the Bohler specifications, this super stainless steel has a rating of 60 – 62 HRC on the Rockwell scale. This hardness level is high and provides an ideal balance of extreme resistance to wear and edge retention. Considering this hardness level, this steel is ideal for outdoor activities.

Properties

The chemical composition of this super steel governs its properties. Let’s explore them:

- Good Toughness: M390 knives are tough. Their resistance to chipping, cracking, and breaking under stress is higher than several other steels with the same hardness level. Some people may argue that M390 is not the toughest steel. While true, it cannot be denied that it’s tough enough for most outdoor knives.

- Extreme Wear Resistance: This super steel exhibits extreme resistance to wear and tear under impact or stress. The credit goes to the high volume of chromium carbides.

- Extreme Edge Retention: Being super steel, M390 ensures excellent edge retention. The credit for high sharpness retention goes to the high carbide content along with vanadium. This means you need not bother about frequent sharpening. Consequently, the lifespan of the blade increases, as frequent sharpening can result in wear and tear. You can trust a genuine M390 EDC to last incredibly for a long time with little care and maintenance.

- High Corrosion Resistance: Carbon and chromium are two main ingredients that contribute to corrosion resistance for a steel alloy, along with other elements such as nitrogen and molybdenum. Well, in M390, the amounts of carbon and chromium are high. This means you can expect excellent corrosion resistance. Therefore, this steel is used for designing knives for use in saltwater or humid environments, wherein the susceptibility to rust is high.

- Ease of Sharpening: Well, you may now think that this is a limitation of M390 super steel. This steel is supposed to be hard to sharpen for yielding a high level of hardness and extreme ability to resist wear. However, M390 is easy to sharpen if you have the right equipment. We would recommend you getting both diamond and ceramic stones for sharpening.

Comparison With Other Knife Steel Options

You now know about the chemical composition and properties of this super steel. That said; it is time to see how does M390 fares against competitive steels in terms of performance.

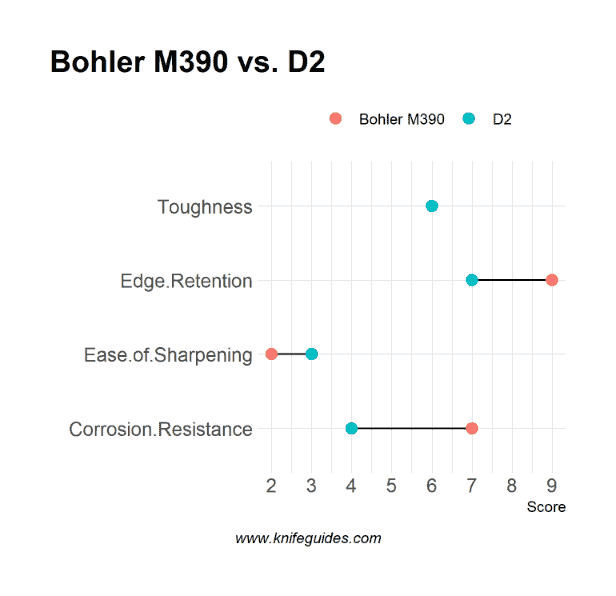

M390 vs D2

Both are tool steels, but their performance differs significantly. the Bohler steel provides higher better edge retention ability and resists wear more significantly than D2. Further, D2 is considered semi-stainless; whereas, M390 is stainless. This means the Bohler steel wins when it comes to corrosion resistance. Nevertheless, D2 is easier to sharpen.

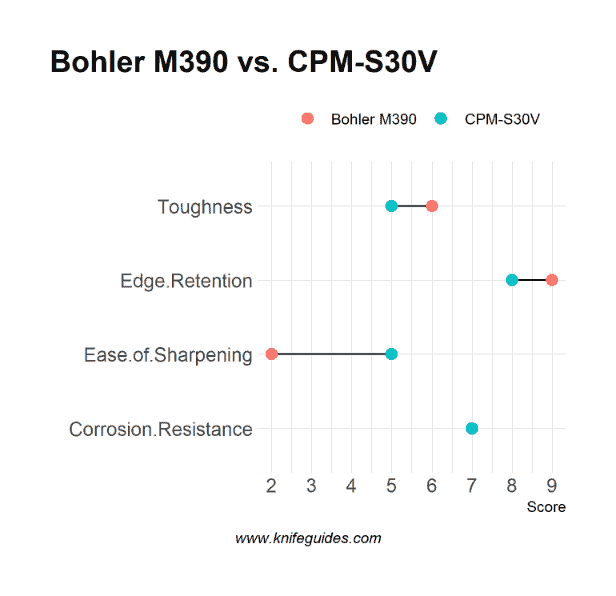

M390 vs S30V

S30V from Crucible is high-end steel. However, M390 offers better edge retention, toughness, and wear resistance. In terms of corrosion resistance, both have a similar rating. However, when it comes to ease of sharpening, S30V clearly wins.

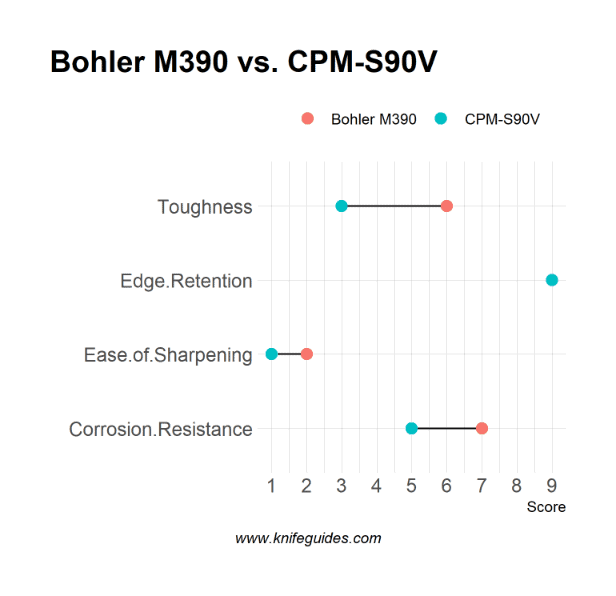

M390 vs S90V

S90V is another steel from Crucible, formulated for delivering extreme wear resistance and supreme edge retention. Still, M390 outperforms in terms of corrosion resistance, toughness, and ease of sharpening.

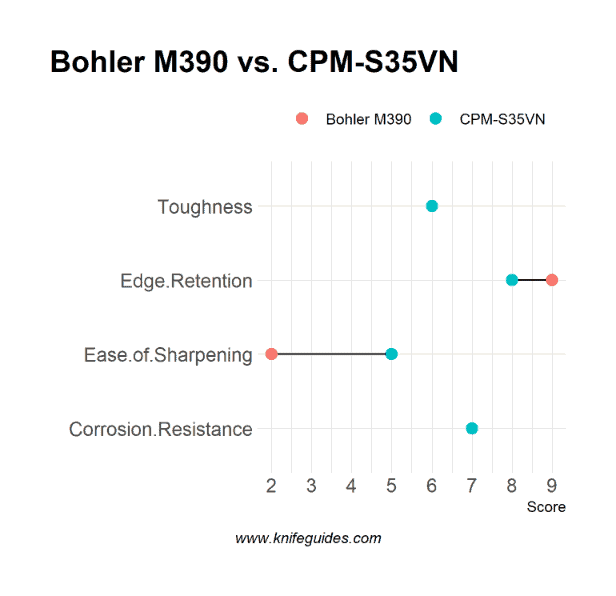

M390 vs S35VN

S35VN from Crucible provides lower edge sustenance than the Bohler steel. M390 edge is difficult to sharpen than an S35VN edge. However, both have the same toughness level and corrosion resistance.

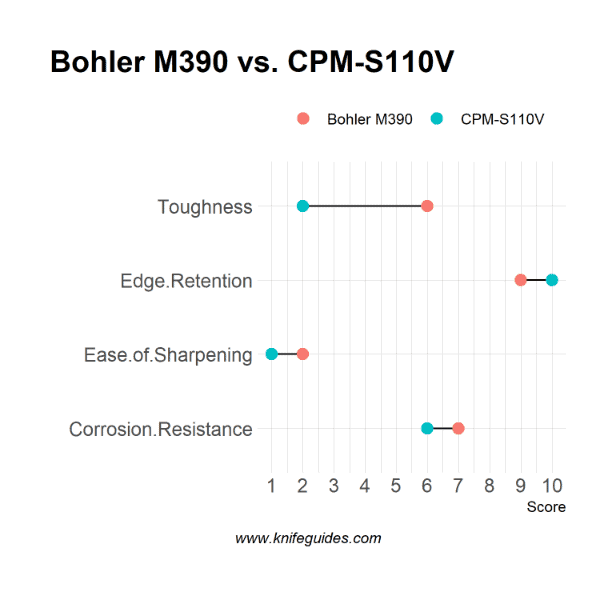

M390 vs S110V

S110V is slightly better at retaining a sharp edge, but, less tough, a bit lower in resisting corrosion, and harder to sharpen than M390. Both are PM steels.

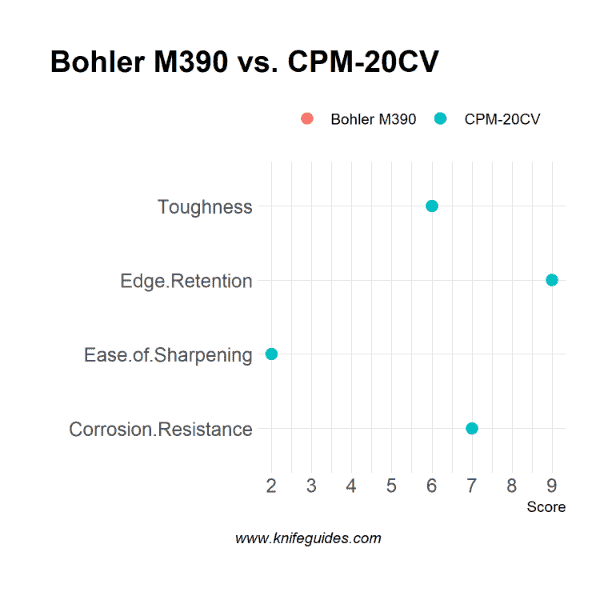

M390 vs 20CV

The 20CV steel from Crucible was introduced as the US version of M390. Hence both steels perform similarly.

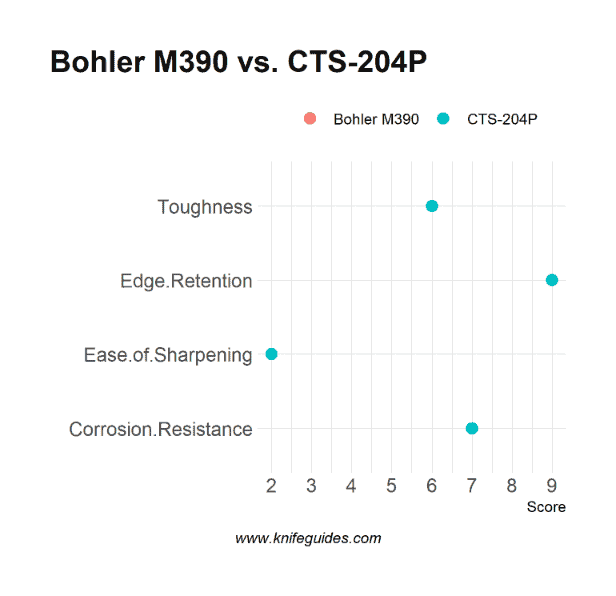

M390 vs CTS 204P

CTS 204P from Carpenter is the US version of M390 steel. Both perform closely on all parameters.

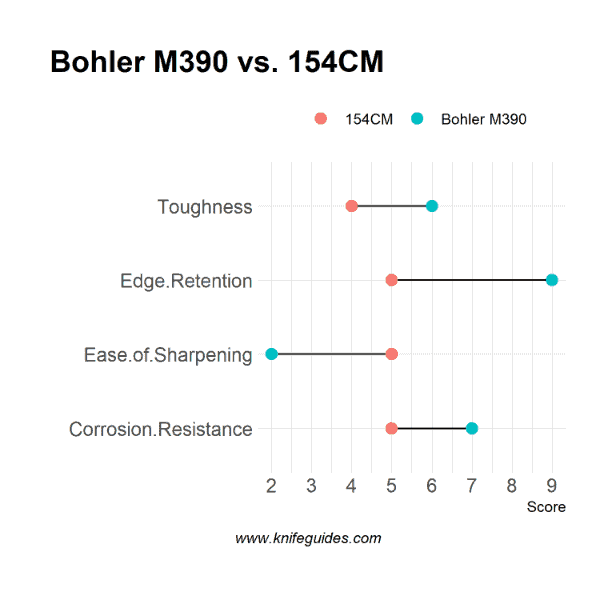

M390 vs 154CM

This Bohler steel beats the Crucible’s 154CM steel with a bit better corrosion resistance and better edge retention. Both are tough, but M390 is a little tougher. It is far easier to sharpen 154CM, though.

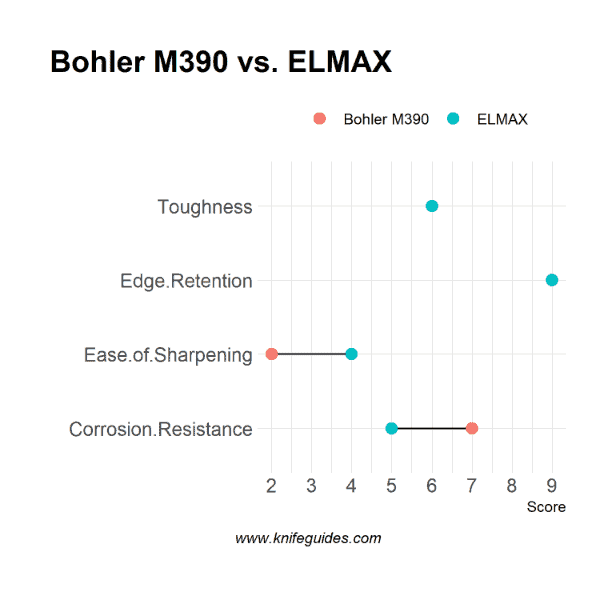

M390 vs Elmax

Elmax is M390’s sibling and features chromium, vanadium, and molybdenum for extreme resistance to corrosion and wear. However, M390 wins in terms of corrosion resistance. It is easier to sharpen Elmax though.

Top Bohler M390 Knives on Amazon

| Image | Title | Price | Buy |

|---|---|---|---|

| Spyderco SpyOpera | Check Price on Amazon | |

| TURENZ M390 | Check Price on Amazon | |

| TwoSun Knives TS72 | Check Price on Amazon | |

| Kizer Deviant | Check Price on Amazon | |

| Bradford Knives Guardian | Check Price on Amazon |

So, is M390 Steel Good?

Bohler M390 is renowned for its all-around performance. It is a premium steel and knives can cost a lot.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.