(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

CPM S90V from Crucible is a super steel variant known for its ability to retain an edge for long, even with frequent heavy-duty usage. It can be categorized with other super steels such as M390, Elmax, CPM 110V (its big brother), and CTS-204P. However, this sounds promotional if you have no idea of this steel’s chemical composition and properties. So, let’s explore them!

What is CPM S90V Steel?

Made by the American brand Crucible, CPM S90V belongs to the family of premium steels. It is one of the steels in the SxxV series, a group of stainless steels formulated using the brand’s Particle Metallurgy (PM) process. C in CPM stands for Crucible.

The brand originally made this steel as tool steel and gave the name CPM 420V. This steel was used for making bearings, slitters, feed screws, valve components, gear pumps, cutters, and other tools for hard use.

Today, CPM S90V is a popular super steel used for designing high-end knives. However, it is expensive, just like other super steels. Moreover, its grindability is not up to the mark; hence working with it is not that easy.

Popular brands such as Benchmade and Spyderco use this steel to make premium knives.

Chemical Composition

CPM S90V contains three main alloying elements in unusually high quantities: carbon, chromium, and vanadium. This blend makes it a type of premium steel. It is also stainless due to its high chromium content. Following are its constituents:

- 2.3% Carbon: For higher hardness as well as greater ability than normal to keep corrosion and wear at bay

- 14% Chromium: For excellent corrosion resistance, toughness, hardness, tensile strength, and edge retention

- 9% Vanadium: For great resistance to wear, toughness, and strength

- 1% Molybdenum: For better strength, hardness, toughness, and machinability

- 0.5% Silicon: For better strength and resistance to corrosion

- 0.5% Manganese: For better hardenability, forgeability, and resistance to wear

- 0.40% Tungsten: For better hardenability, strength, and toughness along with hardness retention at high temperatures

- 0.03% Phosphorus: For better hardness, machinability, and strength

- 0.03% Sulfur: For better machinability

Steel Hardness

On the Rockwell scale of hardness, CPM S90V has a rating of 57-59 HRC. According to knifesteelnerds.com, this hardness level can go up to 66 HRC depending on the heat treatment. This is truly a high level of hardness!

Even the range of 57-59 HRC is considered a great hardness level. This is generally the hardness level range of steels used to make the high-quality EDC and other premium knives.

Properties

- Okay Toughness: Considering the hardness level of 57-59 HRC, this steel provides decent toughness. Yes, it is not the best, as with a high hardness level comes a low level of toughness. In terms of toughness, S90V falls behind steels such as S30V and S35VN, but you can compare it with that of D2. The toughness level of this steel is attributed to the PM process known for its uniform distribution of carbides. Vanadium carbide content is quite hard and significantly contributes to wear resistance but is unfavorable for toughness in traditionally produced steels. Nevertheless, in powder metallurgy steels, these carbides are small, and they can contribute to toughness more than other types of carbides. Thus, S90V can withstand a fair bit of abuse without breaking.

- Excellent Wear Resistance: This is one of the most commendable benefits of using an S90V knife. You can expect it to resist wear and abrasion in any circumstances. The credit goes to the high vanadium content from vanadium carbides. These super-hard carbides significantly contribute to extraordinary wear resistance. It enables this steel to endure lots of hard use without any signs of wear or tear. Even the shape remains intact for longer periods.

- Moderate Corrosion Resistance: Due to high carbon and chromium content levels, this Crucible steel will not rust quickly. The 14% chromium content makes it stainless, and all stainless steels are resistant to corrosion. Another factor that ensures corrosion resistance is the presence of vanadium carbides. You can expect better corrosion resistance than its precursors but lower resistance than its more-molybdenum-rich upgrades such as S110V.

- Superior Edge Retention: The high chromium and vanadium quantities in the chemical composition of S90V lead to superior wear resistance. This gives the steel the ability to retain a sharp edge for a very long time. This ability is superior to the standard stainless steel options. It is better than the former PM stainless steel variants such as S30V. The blade will not become dull quickly whether you use it for light or heavy-duty jobs.

- Ease of Sharpening: Because of its high hardness level, it isn’t easy to sharpen this steel. This steel has vanadium carbides that ensure an exceptionally high level of wear resistance. As a result, most sharpening stones hardly have any impact on them. For sharpening such a kind of steel, it is essential to use a sharpener that is harder than the vanadium carbides, such as a diamond or CBN stone. You will need saintly patience for sharpening a CPM S90V steel blade. However, in return, you get a longer-lasting edge.

Comparison With Other Knife Steel Options

Now, let’s compare CPM S90V with other steels in terms of different parameters such as corrosion and rust resistance, ease of sharpening, hardness, and toughness.

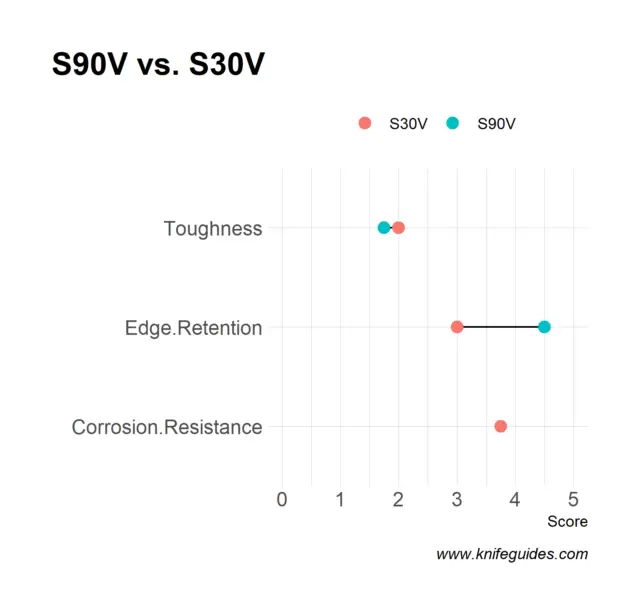

S90V vs. S30V

CPM-S90V boasts a better edge retention ability than its younger brother S30V. But S30V easily surpasses S90V in terms of toughness and ease of sharpening.

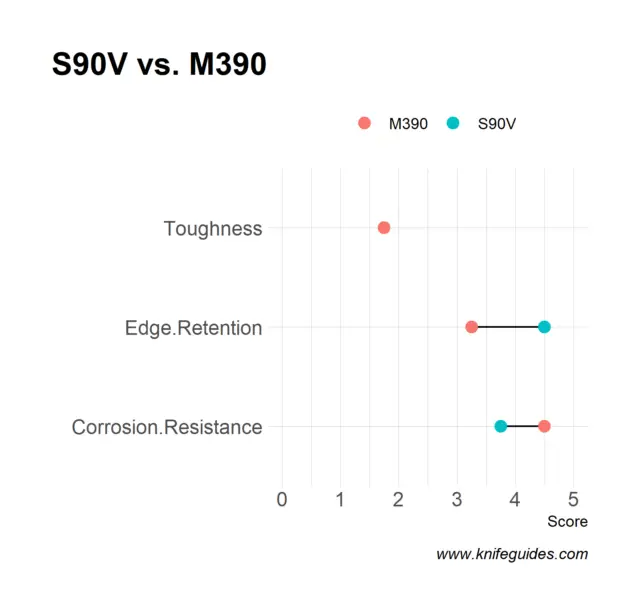

S90V vs. M390

Both are premium steels, but the American steel wins in edge retention. However, Bohler M390 wins when it comes to ease of sharpening, resistance to corrosion, and toughness.

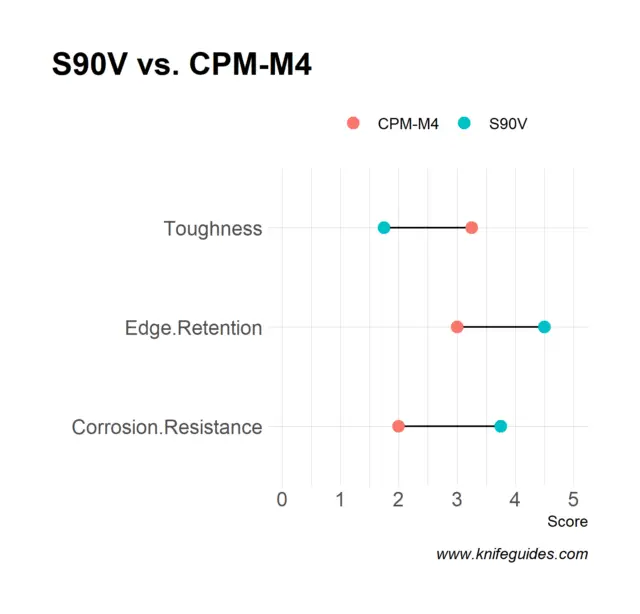

S90V vs. M4

CPM-M4 is also made using the PM process and is a premium stainless tool steel. It is tougher and easier to sharpen. However, S90V is better at edge retention and is more resistant to corrosion than M4.

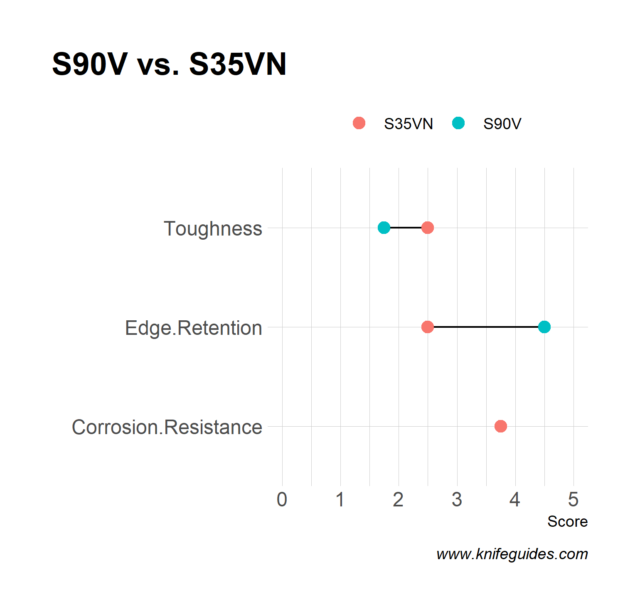

S90V vs. S35VN

S90V overcomes S35VN in terms of edge retention. However, S35VN is admired for its better performance in other areas such as toughness and ease of sharpening. Furthermore, S35VN is more popular too.

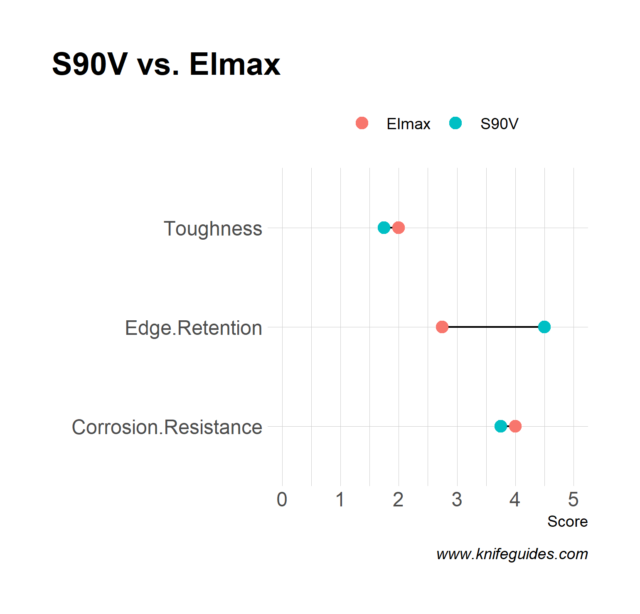

S90V vs. Elmax

Elmax from Bohler is an alloy with high vanadium, chromium, and molybdenum levels. These steels have almost the same performance level in corrosion resistance and toughness. However, the Crucible steel is much better in edge retention.

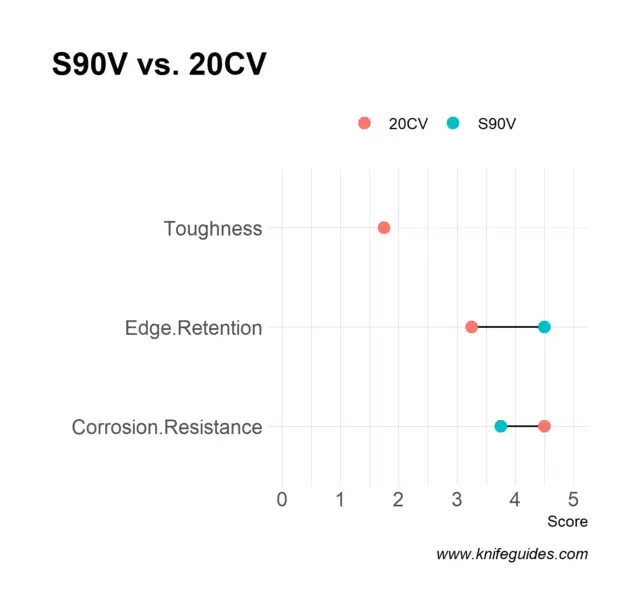

S90V vs. 20CV

CPM 20CV is better at corrosion resistance and ease of sharpness. But S90V is much harder, hence better at edge retention, yet both the steels score the same in toughness.

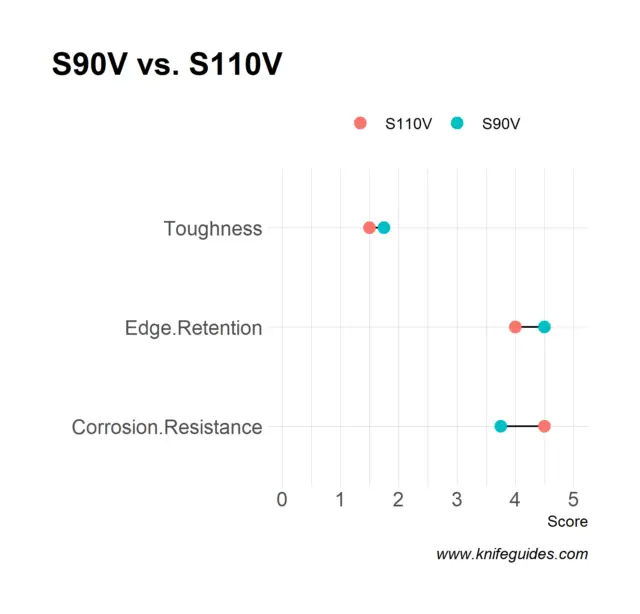

S90V vs. S110V

Both are premium steel options from Crucible. Both are very hard and have high edge retention. But, S90V is better at edge retention and toughness, and S110V is much better at corrosion resistance.

S90V offers somewhat better toughness and edge retention making it more balanced for applications that need only medium corrosion resistance. If more corrosion resistance is required then S110V is the way to go. –Knifesteelnerds.com

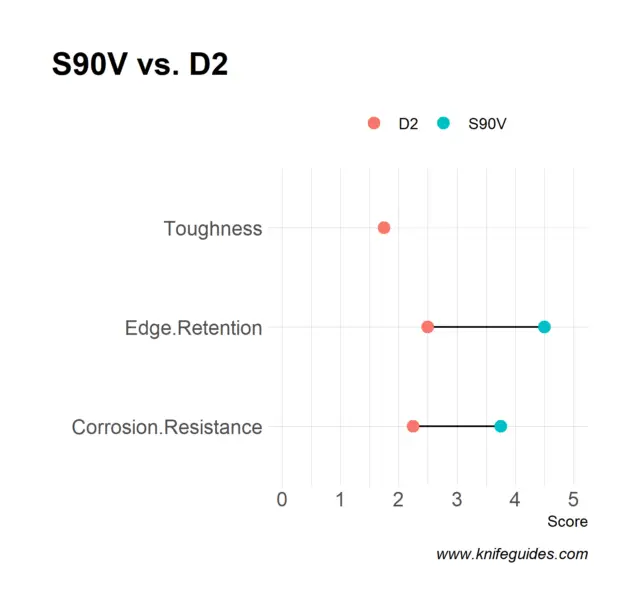

S90V vs. D2

D2 is a midrange steel option with lower hardness. Hence D2’s performance in terms of edge retention is poor. The Crucible steel being stainless is also much better at corrosion resistance as well.

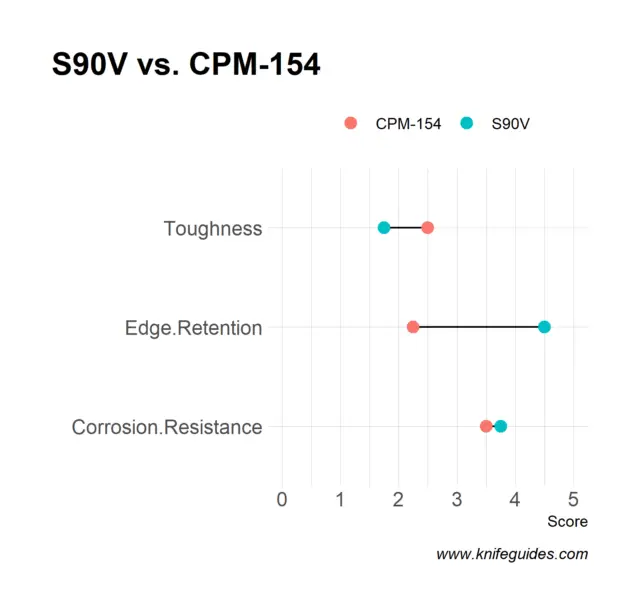

S90V vs. CPM 154

CPM 154 is a high-end steel option, yet is no match for S90V in hardness and edge retention. Both are almost similar in corrosion resistance though.

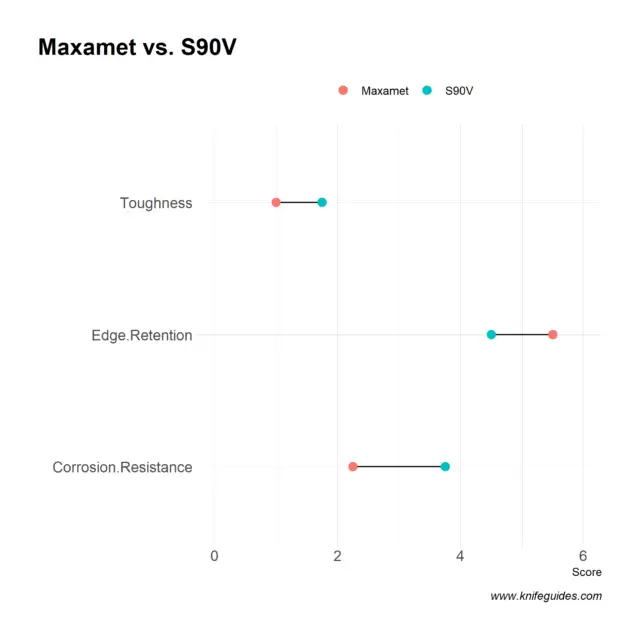

S90V vs. Maxamet

Maxamet is a high-speed steel option from Carpenter. High-speed steels are much harder than any other steel option. Hence Maxmaet is much better in terms of edge retention. In terms of corrosion resistance the Crucible steel wins by a large margin.

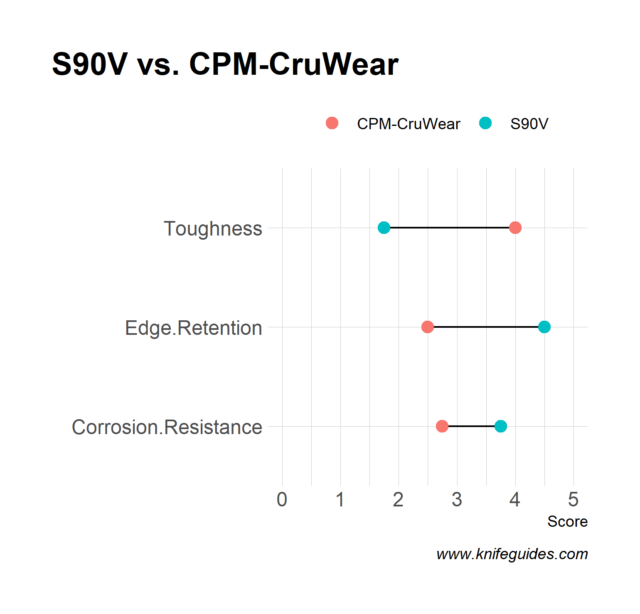

S90V vs. CruWear

CPM CruWear is an air-hardening tool steel option possessing an excellent combination of high wear resistance and toughness. But in terms of edge retention and corrosion resistance the stainless steel scores much better.

So, is S90V Steel Good?

As a super steel option for premium knives, S90V provides exceptional resistance to wear, moderate resistance to corrosion, and great edge retention. It is also moderately tough enough to withstand a fair bit of abuse.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.