(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

If you have seen threads about CruWear in knife forums, you will find that most users are a fan. CruWear from Crucible has all the desirable properties for a knife blade. It’s readily available too. On the flip side, CPM CruWear knives are relatively costlier.

Let’s dive deep into its properties and chemical composition.

What is CPM CruWear Steel?

Made by the American brand Crucible, Cru-Wear or CruWear is an air-hardening tool steel. It is formulated using the brand’s Crucible Particle Metallurgy (CPM) process. It is regarded as an upgrade to the simple CruWear and D2 steels made by the same brand to make it harder, tougher, and more resistant to wear.

CruWear comes with high machinability, and it tempers better than D2, both of which are appealing to knife makers. Improved tempering helps it in adopting surface treatments well. This steel is widely used in making different types of dies, knives, and shear blades.

You can find Benchmade, Boker, and Spyderco knives with a CPM Cruwear blade.

Chemical Composition

CPM CruWear is not stainless. As the carbon content is high, it is a part of the high-carbon steel family. Following are the different elements of this steel:

- 1.10% Carbon: For more hardness and improved resistance to wear and corrosion

- 7.50% Chromium: For more tensile strength, hardenability, and resistance to corrosion

- 2.48% Vanadium: For more toughness, strength, and resistance to wear as well as corrosion (latter being possible due to the contained oxide coating)

- 1.60% Molybdenum: For more hardenability, strength, toughness, hardness, and machinability

- 1.15% Tungsten: For more hardenability, hardness at high temperatures, strength, and toughness

Steel Hardness

On the Rockwell scale, the hardness rating of CPM CruWear ranges from 60 to 65 HRC. This range of hardness levels is considered high. However, the exact value will differ as per the given heat treatment.

The credit for being so hard usually is given to the high carbon content. However, it is also due to sufficient tungsten and molybdenum content.

Steel Properties

- Exceptional Toughness: Considering the high hardness range of this tool steel, it is obvious to infer that it would be less tough. However, this steel is an exception, as it is incredibly tough. According to the Crucible’s datasheet, this steel is tougher than plain CruWear and D2. The credit for this high toughness level goes to the brand’s CPM process that reduces the size of carbides and evenly distributes toughness. Thus, a CPM CruWear steel knife is highly resistant to breakage and chipping, especially when under pressure.

- High Wear Resistance: High wear resistance is the typical benefit you can expect from any typical tool steel. The higher the hardness, the more is the power to keep wear and tear at bay. This is attributed to the ideal carbon, vanadium, tungsten, and chromium mix.

- Superb Edge Retention: This is another commendable property of CPM CruWear. This high-end steel takes a sharp edge and holds it well. Many users say that a CruWear knife can chop down a jungle before getting dull.

- Okay Corrosion Resistance: Indeed, this steel is not stainless due to low chromium content. However, 7.5% chromium contributes to okay resistance to corrosion and rust but will rust in salty conditions. You can get knives with an anti-corrosion coating to ensure better resistance.

- Ease of Sharpening: Great toughness, high resistance to wear, and high hardness make any steel hard to sharpen. However, this steel is an exception even here. You can easily sharpen a CPM CruWear blade, even using a low-grade abrasive to get a very sharp edge. It is also possible to sharpen it on a stone.

Comparison With Other Knife Steel Options

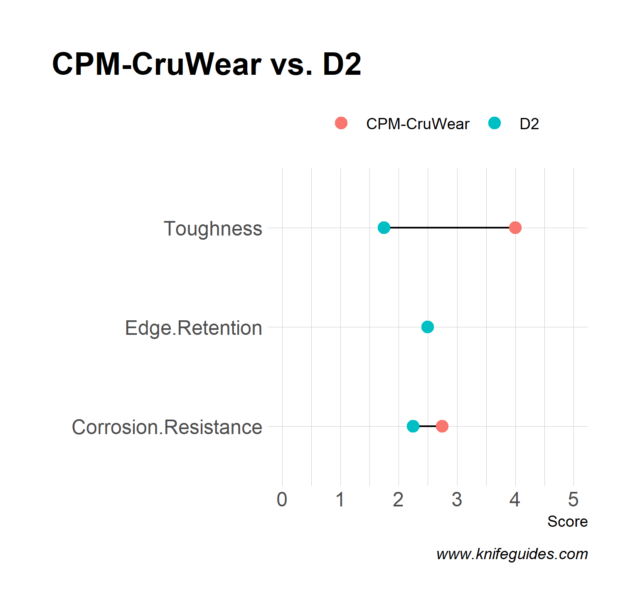

CPM CruWear vs. D2

CruWear is a bit harder than D2. Both steels have carbides for resisting wear, but due to higher vanadium carbide content, CruWear is harder. Typically, vanadium carbides are harder than chromium carbides and are more effective in resisting wear. CruWear is also tougher and is better at corrosion resistance than D2.

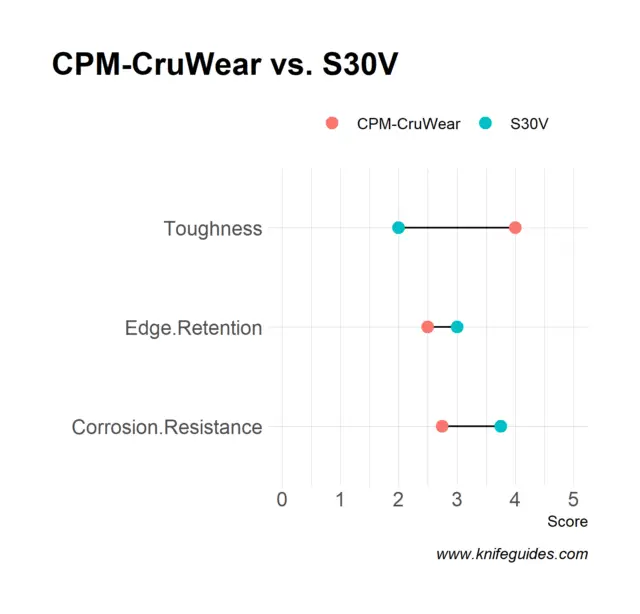

Cru-Wear vs. S30V

S30V is a premium-grade material from Crucible. It is more resistant to corrosion because of its high chromium content. Further, it is harder than CruWear and has better wear resistance and edge retention. On the other hand, CruWear is tougher and easier to sharpen than S30V.

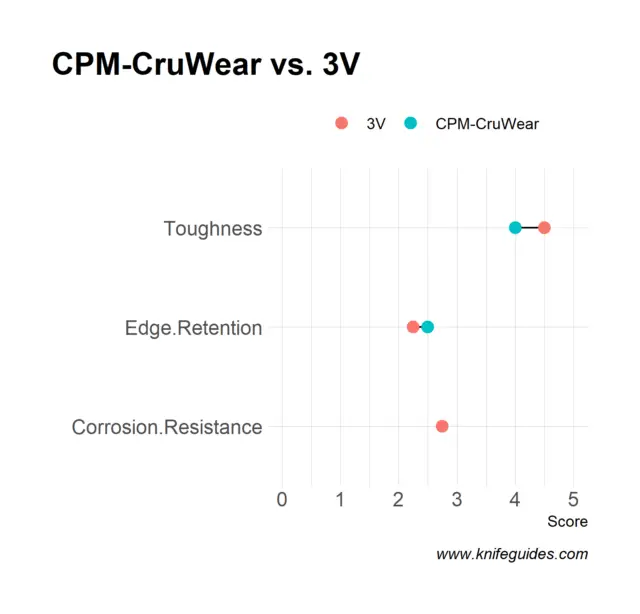

CPM CruWear vs. CPM 3V

3V also comes from Crucible. The amount of carbon in 3V is less, due to which it is less hard than CruWear. This means CPM 3V will not retain a sharp edge as good as CruWear. However, the higher vanadium and molybdenum contents in 3V make it tougher. Due to the same amount of chromium, both steels perform similarly in corrosion resistance.

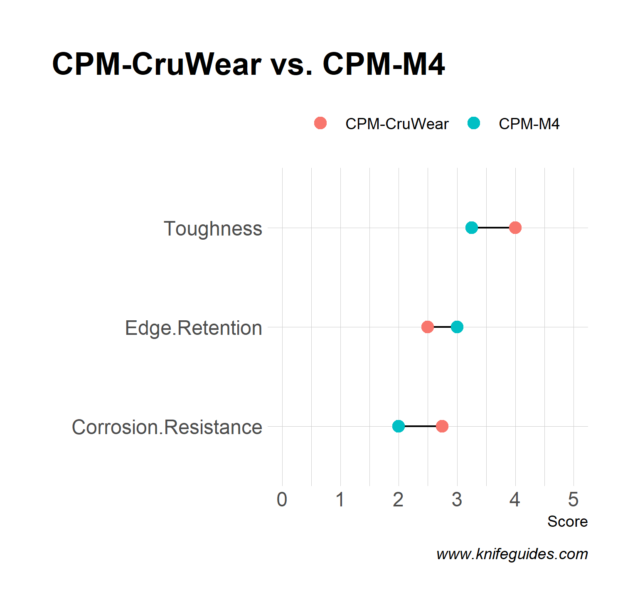

CruWear vs. M4

CruWear wins over M4 in corrosion resistance due to higher chromium content. However, CPM M4 has more carbon than CruWear; hence it is better at edge retention. It is also more resistant to wear than CruWear. However, CruWear is easier to sharpen. CruWear also gains an edge due to better impact resistance in terms of toughness.

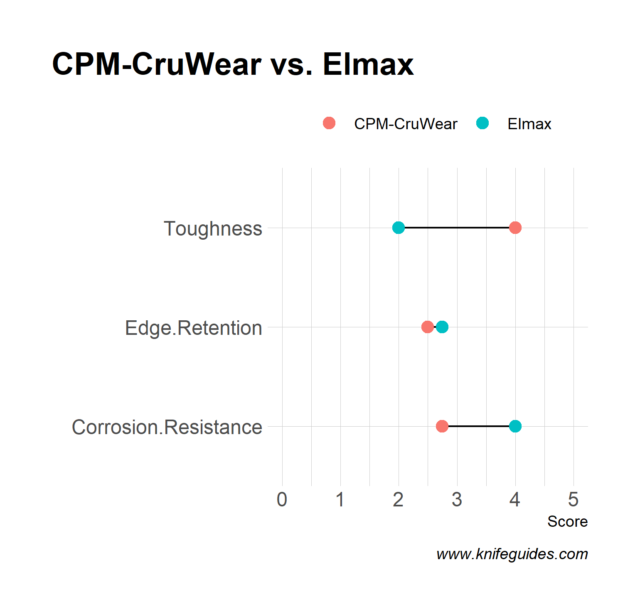

CruWear vs. Elmax

Both have similar performance at retaining an edge and resistance to wear. Due to more chromium content, Elmax resists corrosion and rust better. However, Elmax is less tough than CruWear.

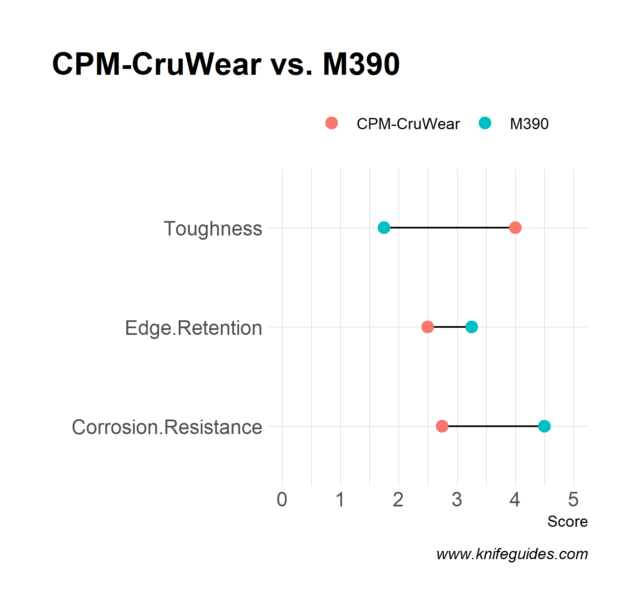

CPM-CruWear vs. M390

Bohler M390 is a premium knife steel with a superior hardness to most knife steel variants. In addition, 390 excels in corrosion resistance and edge retention, whereas CruWear is tougher.

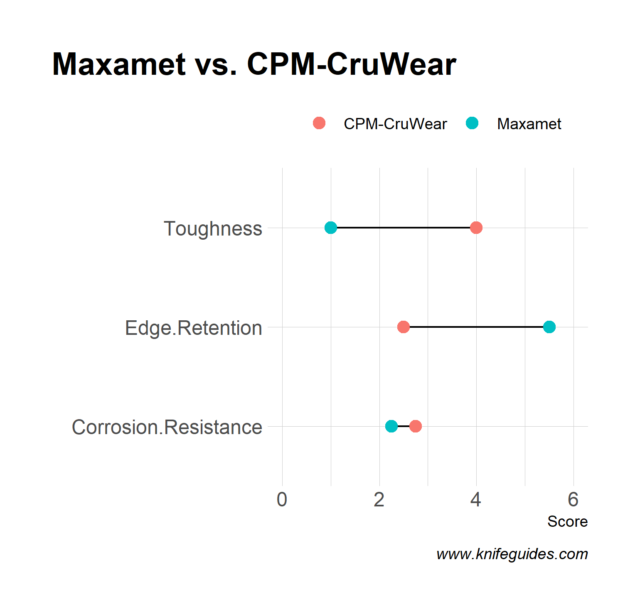

CPM-CruWear vs. Maxamet

Maxamet is one of the hardest steel out there. Hence it is excellent at edge retention and wear resistance.CruWear fares better in corrosion resistance, though.

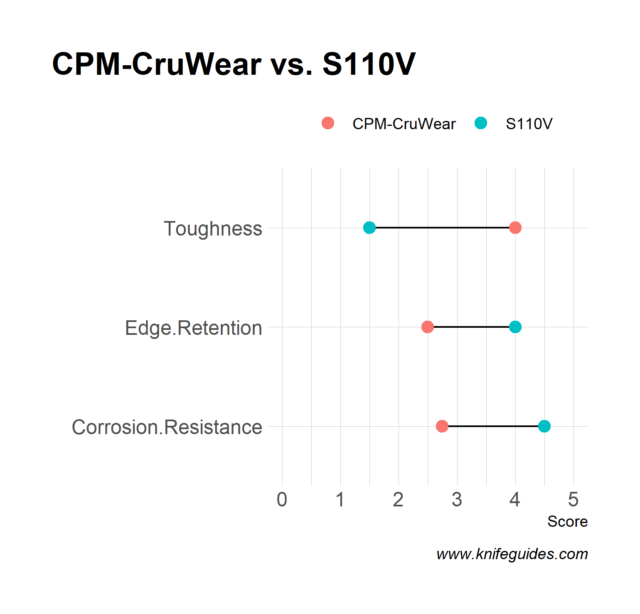

CPM CruWear vs. S110V

S110V is another premium steel from Crucible with great hardness. It is far better at edge retention and corrosion resistance than CPM-CruWear.

So, is CruWear Steel Good?

CPM CruWear has a perfect balance of hardness, edge retention, toughness, ease of sharpening, and machinability. Despite not being stainless, this high-carbon steel also offers okay corrosion resistance compared to other high-carbon steels. However, be warned that the steel will rust in salty conditions.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.