(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

Benchmade and Spyderco have an array of knives made of CPM M4 blades. Most of these knives have gathered excellent reviews from knife enthusiasts. So, is M4 an ideal option for everyone? This post explores its chemical position properties and benchmarks its performance against its peers.

What is CPM M4 Steel?

Commonly referred to as M4, CPM M4 is a premium high-speed tool steel featuring high contents of vanadium and molybdenum. Hence the steel has an ideal blend of high wear resistance and high-impact toughness, making it a popular choice for making outdoor knives.

CPM M4 is powdered tool steel formulated by Crucible. As the name suggests, it is made using the brand’s Compacted Powder Metallurgy (CPM) process. It was specially formulated to introduce improvements to the M2, M3, and M7 grades of steel in terms of toughness and wear resistance. Thus, it is one of the top options for premium and custom knives.

Chemical Composition

This tool steel features unusually high tungsten, molybdenum, and vanadium content. It also features more carbon content, due to which it belongs to the category of carbon steels. However, as the chromium content is only about 4%, CPM M4 is not stainless.

- 1.42% Carbon: For more hardness and a higher ability to resist wear and corrosion than normal

- 5.5% Tungsten: For more toughness as well as strength

- 5.25% Molybdenum: For more machinability as well as strength

- 4% Chromium: For superb edge retention, toughness, tensile strength, hardness, and resistance to corrosion and wear

- 4%: Vanadium: For more resistance to shock loading, toughness, hardenability

- 0.55% Silicon: For more strength

- 0.30% Manganese: For better hardenability, forge ability, tensile strength, and resistance to wear

- 0.06% Sulfur: For better machinability and impact toughness

- 0.03% Phosphorus: For better machinability, strength, and hardness

Steel Hardness

According to Crucible, this premium tool steel has a hardness rating ranging from 63.5 to 65.5 HRC on the Rockwell scale. This is considered high, and the credit goes to high carbon and tungsten content. This alloy prevents surface deformation, scratching, and penetration with high hardness.

Properties

- High Toughness: This steel is extremely tough and scores higher in this area than other popular steel variants. Harder steels are indeed less tough. Thus, you may be wondering why M4 is both tough and hard. This steel is tough because of PM technology and high vanadium and tungsten content. The high level of toughness justifies why it is a tool steel. A CPM- M4 steel knife blade will not chip or break easily while under any lateral force.

- Exceptional Edge Retention: CPM M4 steel ensures outstanding edge holding ability. This is attributed to its high hardness level. As a result, M4 provides better edge retention than other renowned steels for their edge retention capability, such as CPM 154, D2, and S30V.

- Excellent Wear Resistance: Considering a high level of toughness hardness and exceptional edge retention ability, this steel can easily keep wear impact at bay. Due to high molybdenum and vanadium content, this steel is tough, hard, and stable. Thus, it will not wear despite frequent abrasive and adhesive damage.

- Corrosion Resistance: As CPM M4 is not a stainless steel, it is prone to rust. It may rust or corrode when exposed to humid or saltwater conditions. Hence you need to clean and dry your blade and lubricate it before storing it. Nowadays, you can also find M4 knives having an anti-corrosion coating to increase their lifespan.

- Ease of Sharpening: As this steel is very hard, it is not easy to sharpen its edge. However, you can still achieve a razor-sharp edge using the right type of sharpener. We would ask beginners to seek professional support, not to sharpen a CPM-M4 edge themselves.

Comparison With Other Knife Steel Options

Let’s now benchmark CPM M4 with other steels regarding toughness, hardness, corrosion and rust resistance, and ease of sharpening.

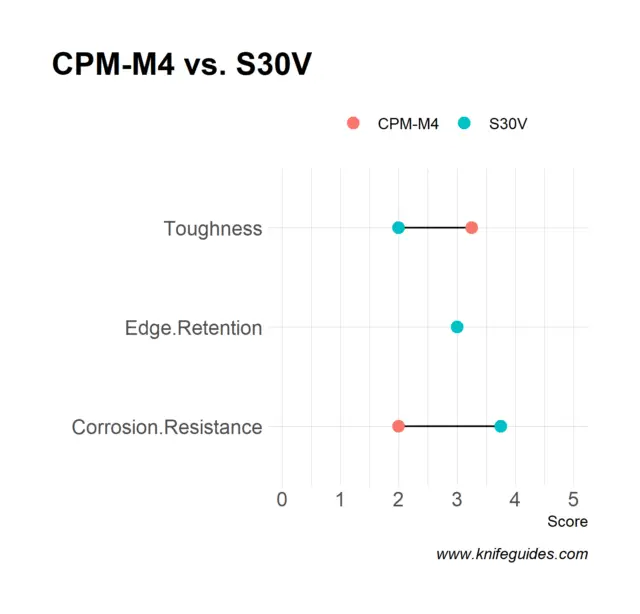

CPM M4 vs. S30V

M4 outshines S30V with higher toughness. However, in terms of corrosion resistance and ease of sharpening, S30V takes the crown.

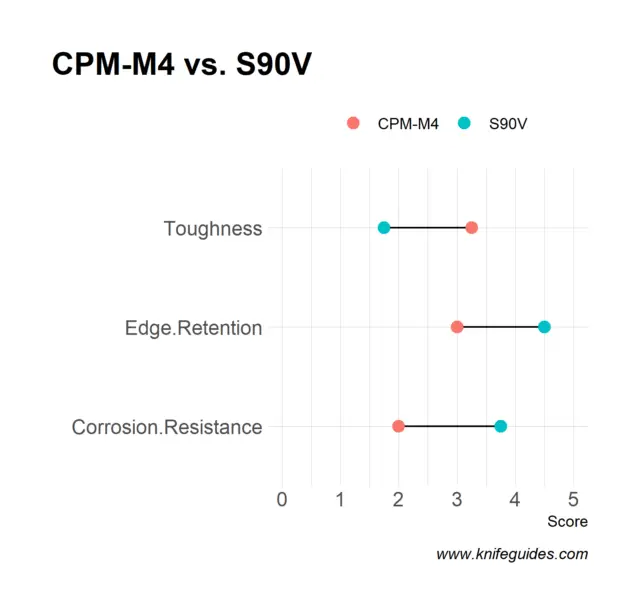

CPM M4 vs. S90V

Both steel variants compete quite closely. However, M4 is much tougher and easier to sharpen than S90V. On the other hand, S90V is better at edge retention and resisting corrosion.

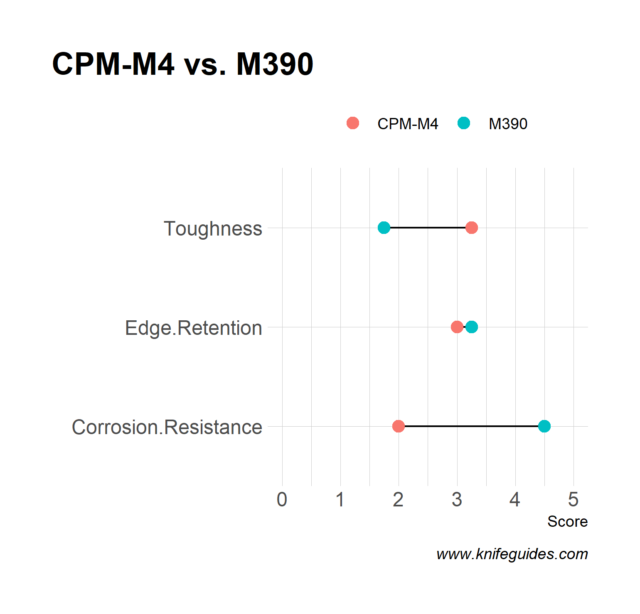

CPM M4 vs. M390

Both steel options have similar toughness, edge retention ability, and ease of sharpness. Nevertheless, M390 takes the crown in corrosion resistance by a large margin.

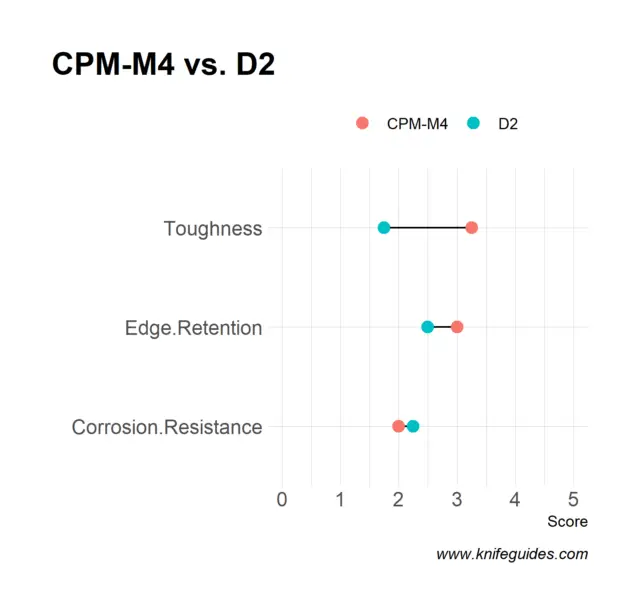

CPM M4 vs. D2

D2 is a type of mid-range, semi-stainless steel. It is more popular and affordable than CPM-M4. However, M4 is tougher and is better at holding an edge sharp for a long time. Both steels are susceptible to stains and rust if proper care is not taken.

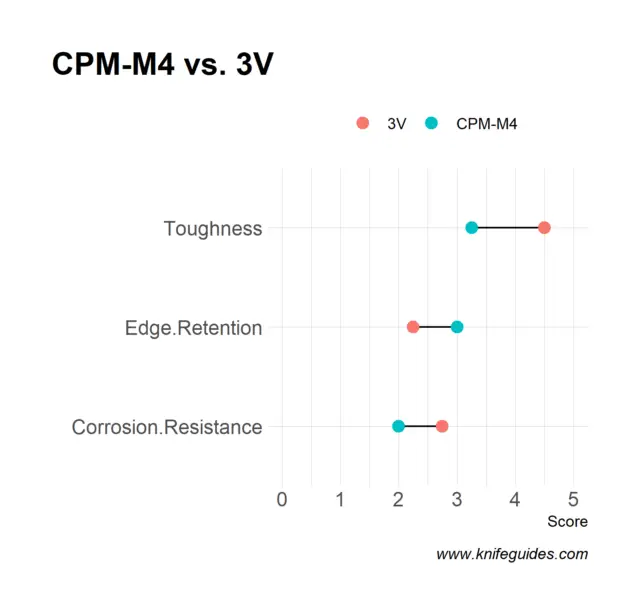

CPM M4 vs. 3V

Both the Crucible steels score high in wear resistance and toughness. 3V is more famous for making fixed blades because of its high toughness. It is also better at the ease of sharpness and corrosion resistance. However, M4 wins when it comes to edge retention.

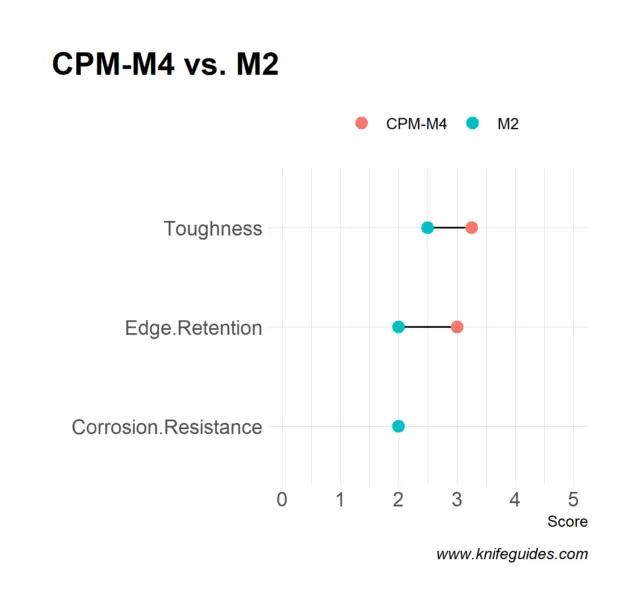

CPM M4 vs. M2

M4 outshines M2 in toughness and edge retention, and as already stated, it was introduced for better wear resistance over M2. M2 is easier to sharpen, though.

So, is CPM M4 Steel Good?

Yes, if you are looking for a tough steel option that retains a sharp edge for an exceptionally long time and is highly resistant to wear. However, a CPM M4 steel knife is difficult to sharpen and prone to corrosion and rust. If you plan to get one, make sure you are getting one with an anti-corrosion coating.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.