(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

As a buyer, you would ensure that the knife you choose is the best bang for your buck. Therefore, it is essential to ensure a good balance among features like edge retention, toughness, resistance to corrosion, and ease of sharpening. Such a balance is found in knives with a CPM 154 blade. As all the important properties are balanced, this steel acts as a versatile option for various knives. Let’s find out more about it in this quick CPM-154 steel review.

What is CPM 154 Steel?

CPM 154 is a type of martensitic stainless steel that the Crucible brand made in the U.S. Formulated first in 2006; this steel is produced by implementing the Crucible Particle Metallurgy (CPM) process, which leads to a finer grain structure.

In addition, the process contributes to easy grindability and polishing while enhancing wear and corrosion resistance and ensuring better hardness and higher toughness. Due to the balanced properties, many custom knife manufacturers find it easy to use this steel.

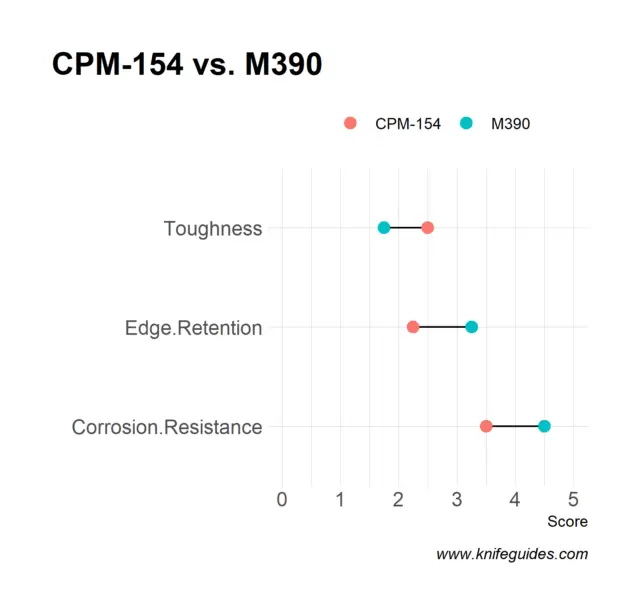

CPM-154 belongs to the family of high-end stainless steels. It is not the same as 154CM steel, as it is a CPM-manufactured form of the brand’s standard 154CM to give you the benefit of the CPM process.

You can trace the roots of CPM steel to the 440C steel. The Crucible brand then considered adding some more molybdenum for enhancing the ability to retain an edge. At the same time, the brand decreased the amount of chromium. Interestingly, this novel steel retained its level of corrosion resistance and was named 154CM.

Chemically, 154CM and CPM-154 seem to be the same. However, the latter is a powder form due to its distinct manufacturing process. This process makes it better than 154CM steel in terms of toughness.

CPM 154 is versatile steel and is used to make various knives, such as premium EDCs and bushcraft knives. It is also used for making cutlery, bearings, and corrosion-resistant tools.

Chemical Composition

CPM 154 contains high amounts of carbon, molybdenum, and chromium. Due to a high level of chromium, it belongs to the category of stainless steel. Below are the components that make up this steel:

- 1.05% Carbon: For increased hardness (but less strength) and better ability to keep wear or corrosion at bay

- 14% Chromium: For terrific tensile strength, great edge retention, and superb resistance to wear and corrosion

- 4% Molybdenum: For more strength and machinability

- 4% Tungsten: For improved hardness as well as resistance to wear

- 0.8% Silicon: For better strength

- 0.5% Manganese: For the enhanced hardness

- 0.4% Vanadium: For better hardenability as well as resistance to wear

- 0.03% Sulfur: For better machinability

- 0.03% Phosphorus: For more strength

Steel Hardness

Because of molybdenum content, this steel is harder than 440C. According to Crucible, CMP-154 has a hardness rating of 58-59 HRC. This rating is considered good, as it is the same level that quality knives have, which come from a few esteemed brands.

However, the exact hardness level seems to vary, as it depends on the heat treatment employed. The rating can, thus, be between 55 and 62 HRC. However, the rating of 59 HRC is common.

Steel Properties

The chemical mix of CPM 154 governs its properties.

- Decent Toughness: This steel is not that hard, which is tough. Remember, toughness and hardness are inversely proportional. In this case, you will obtain both good hardness and decent toughness. In other words, you get the right balance of both properties. Thus, it will not chip or crack easily. This is the reason why it is used for making outdoor knives.

- Excellent Edge Retention: As the hardness level can be as high as 62, you can expect excellent retention of a sharp edge. This means you can expect the sharpness to stay long despite frequent use outdoors. Again, the credit for this property goes to its high chromium and carbon levels.

- Great Wear Resistance: Whether you use CPM 154 knives for camping or cutting tough things, they are made to last. This is because of more than 1% carbon in the chemical composition of this steel. As a result, it will not wear easily or quickly.

- Good Corrosion Resistance: CPM 154 is pure stainless steel due to 14% chromium content. Thus, it is reasonably resistant to corrosion and stains. Although it may not have better anti-corrosion properties than its high-end counterparts, it will fight well against corrosion.

- Ease of Sharpening: It is not very easy to sharpen this steel edge compared to a softer steel variant. At the same time, it is not very hard to do so compared to a harder steel variant. However, this is not a major concern, as the steel retains its sharp edge for a long time. This means you need to sharpen it only occasionally.

Comparison With Other Knife Steel Options

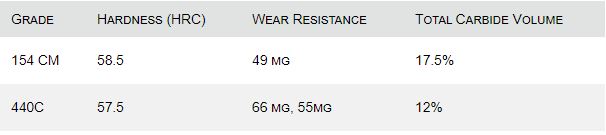

CPM 154 vs. S30V

CPM 154 is very close to S30V when it comes to balancing toughness, hardness, and resistance to wear. Still, S30V wins the crown by offering better corrosion resistance and being better at retaining the edge.

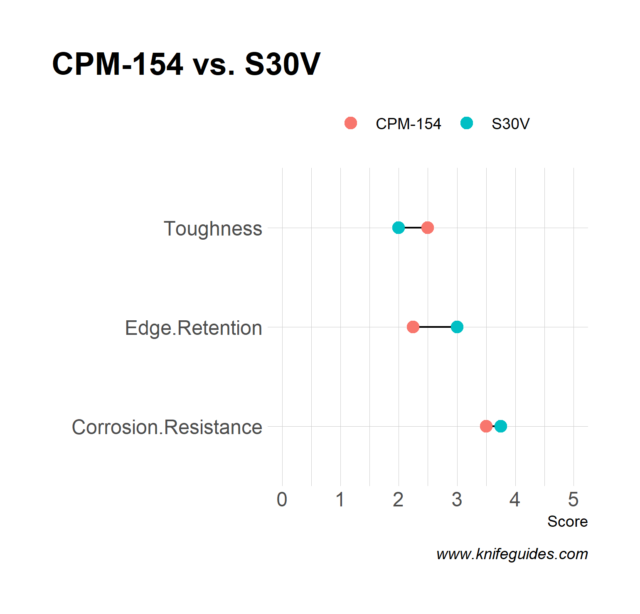

CPM 154 vs. 154CM

Both ensure almost the same performance. Nevertheless, CPM 154 is considered superior to 154CM because it is tougher and is easier to grind and finish.

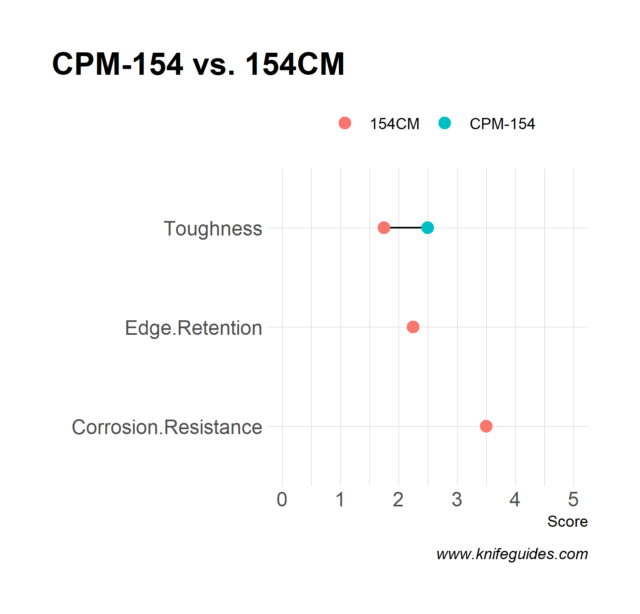

CPM 154 vs. M390

The latter steel is an ultra-premium steel grade. In addition, it is a super steel having a higher hardness rating. Thus, M390 ensures higher edge retention and improved corrosion and wear resistance. However, it is easier to sharpen CPM 154. Further, it is tougher and is less likely to chip.

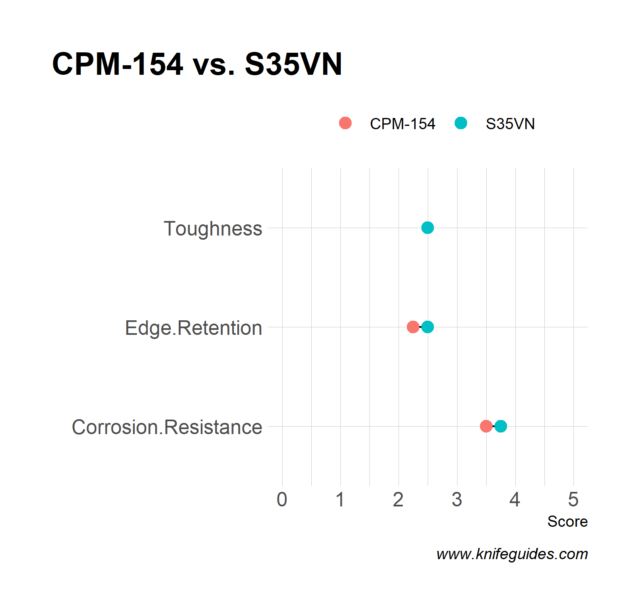

CPM 154 vs. S35VN

While CPM 154 is a high-end steel grade, S35VN belongs to the premium tier of this category. S35VN is a bit better at edge retention as well as corrosion resistance. On the other hand, the CPM steel is easier to process (manufacturing) and sharpen.

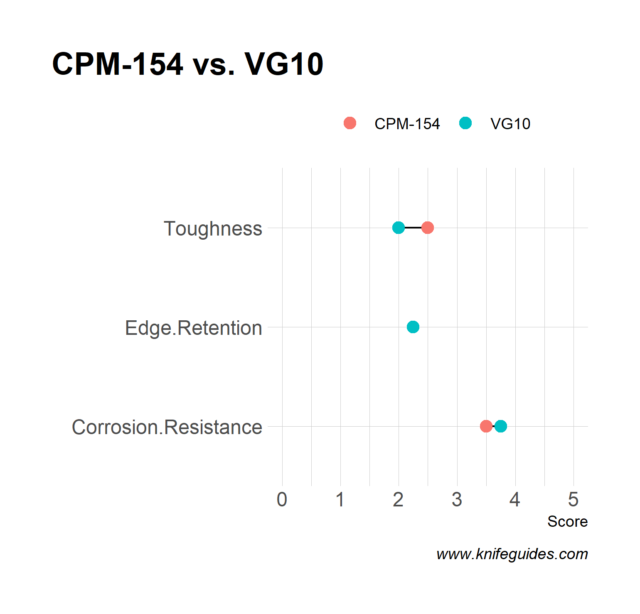

CPM 154 vs. VG10

The Japanese steel, VG10, ensures better corrosion resistance than CPM 154, but it is less tough.

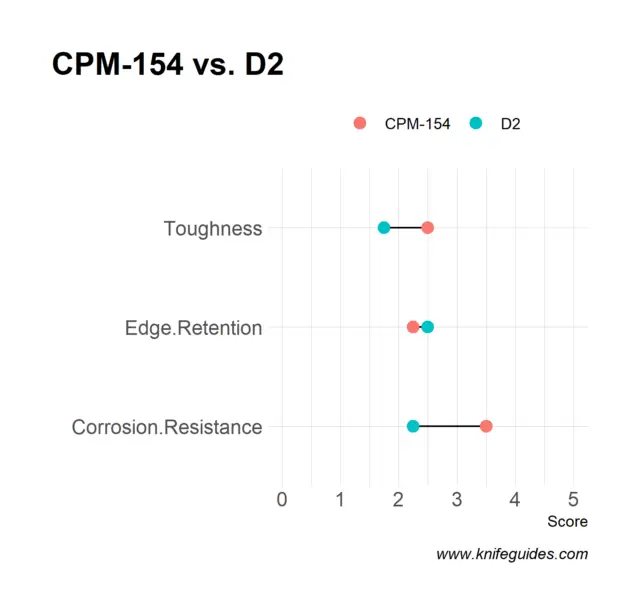

CPM 154 vs. D2

Both are mid-range steels. While CPM 154 wins better resistance to wear, D2 is better at edge sustenance. As D2 is semi-stainless steel, it is not as good as the CPM steel resisting corrosion. However, D2 is easier to process and has a higher grind rating.

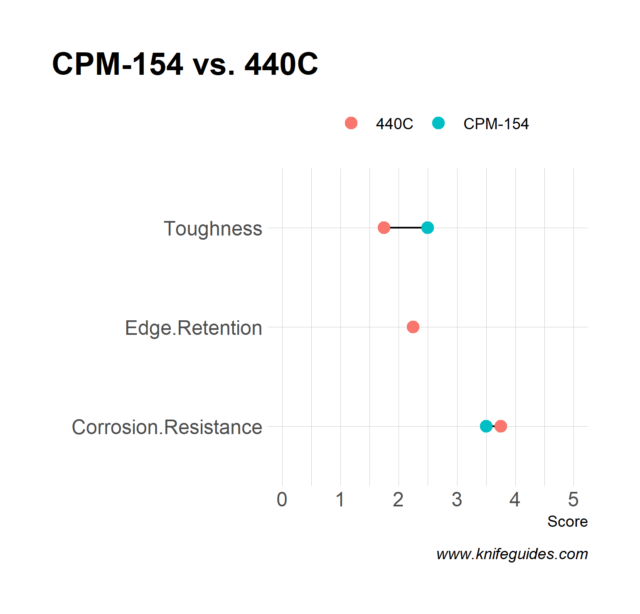

CPM 154 vs. 440C

The major difference comes from toughness. In everything else, both steels score almost the same.

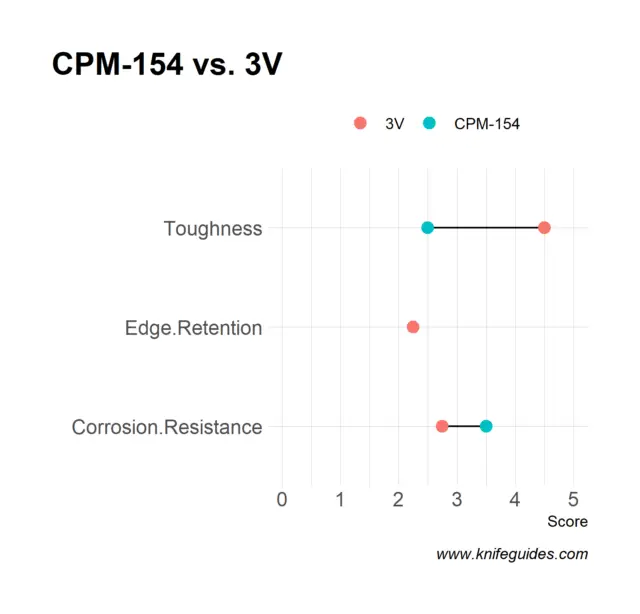

CPM 154 vs. 3V

CPM 3V is much better at toughness; on the other hand, CPM-154 is better at corrosion resistance.

So, is CPM 154 a Good Knife Steel?

Yes! CPM 154 is a good steel option due to its great edge retention ability and a good balance amongst toughness, hardness, and corrosion resistance. Due to these properties, it is chosen for making EDC knives, outdoor knives, and kitchen knives. Although corrosion resistant, it is essential to keep your knife dry after use and lubricate it occasionally.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.