(This site is reader-supported. When you buy something using retail links on our articles, we may earn a small commission. As an Amazon Associate I earn from qualifying purchases.)

LC200N is a great knife steel for humid environments. It is one of the high-end steels used in making knife blades. Spyderco already has an array of knives made of this steel. Let’s explore its chemical composition and properties.

What is LC200N Steel?

LC200N is a new European steel, first introduced in 2013. It’s a high-nitrogen tool steel specifically designed for extremely high corrosion resistance.

It is formulated using the Pressurized Electric Slag Remelting (PESR) methodology. Hence, it has a refined microstructure and boosted cleanliness, contributing to high polishability and machinability. In addition, this steel is known to have the best properties of CPM 154 and is very close to the corrosion resistance of H1.

This steel is made by the Zapp Group. It came up with this steel for processing applications involving dynamic loads in high-temperature and corrosive environments. The steel is also known as Z-FiNit, wherein Z represents Zapp and FiNit is the short form of Fine-grain Nitrogen steel.

It is extensively used in the pharmaceutical, recycling, chemical, and food industries. Like many other knife steels, it was not initially formulated for making knives. However, it offers stunning performance in terms of some properties, due to which it is suitable for making knives.

NASA also used this steel for making ball bearings for their state-of-the-art aerospace equipment instead of using Cronidur 30 bearing steel. The latter is quite similar to LC200N steel in terms of chemical composition and has been around for a long time.

Chemical Composition

This tool steel has >13% chromium content. Thus, it is stainless. Below are the components of this high-nitrogen tool steel:

- 0.30% Carbon: For increased hardness, tensile strength, and resistance to wear as well as abrasion

- 15% Chromium: For more toughness, edge retention, tensile strength, and hardness

- 1% Manganese: For more tensile strength, resistance to wear, and hardenability

- 0.95% Molybdenum: For improved strength, toughness, and hardness

- 0.5% Nickel: For improved toughness but decreased hardness

- 0.5% Nitrogen: For improved resistance to corrosion, edge retention, and strength

In terms of chemical composition, apart from Cronidur 30, Bohler-Uddeholm’s N360 is equivalent to LC200N. Both are stainless steels and have a medium carbon content. They are admired for their ability to keep stains away. However, N360 contains silicon that is absent in LC200N. Both steels are expensive.

Steel Hardness

On the Rockwell scale, the hardness rating of this European steel is in the range of 58 to 61 HRC. This range puts this steel in the same group of steels such as 154CM, S35VN, and VG10. So you can rely on an LC200N knife blade having this range of hardness to ensure super sharpness for longer and better wear resistance than the cheaper ones.

Steel Properties

- Toughness: Considering the high hardness level, this steel is not the best option if you wish to have extremely tough steel that will never chip. However, it is reasonably tough. The level of toughness is similar to that of the H1 steel. The decent toughness level makes it a good choice for making fishing, hunting, and filleting knives.

- Excellent Corrosion Resistance: With its exceptional rust resistance ability, LC200N can endure lots of sweat, salt water, and water without staining. As it is stainless, it is rustproof. This is the primary reason it is the best choice for making kitchen and fishing knives. After all, it is already in use in food, pharmaceutical, and chemical industries, wherein corrosion resistance is indispensable to counter moisture in the air.

- Moderate Edge Retention: The ability to retain a sharp edge is moderate.

- Decent Wear Resistance: As the hardness level is not very high, the power to resist wear is not that high. Both these attributes are directly proportional. LC200N has a good power to resist daily wear and wear. It also prevents the edge from distorting as you cut items with its blade.

- Ease of Sharpness: Sharpening an LC200N edge is easy, as it is not that hard steel. Even the fine grain structure of this steel contributes to easy sharpening and razor-like sharp output.

Comparison With Other Knife Steel Options

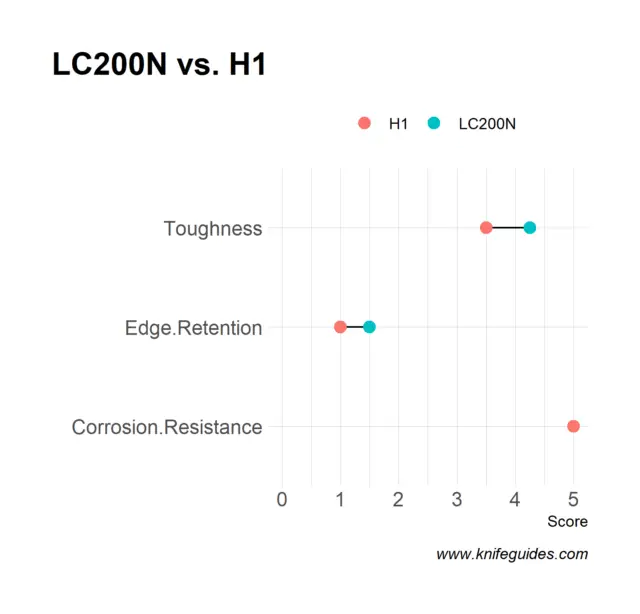

LC200N vs. H1

Both are nitrogen steels and are known for their extraordinary corrosion resistance. Several experts deem LC200N to be the upgraded form of H1, a softer steel option. The former wins over H1 in terms of edge retention, as H1 becomes dull quickly when used for hard tasks.

On the other hand, H1 wins in terms of toughness such that it withstands tough use. H1 is also easier to sharpen.

It has also been seen that H1’s performance is better if the edge is serrated, while LC200N performs better when the edge is plain.

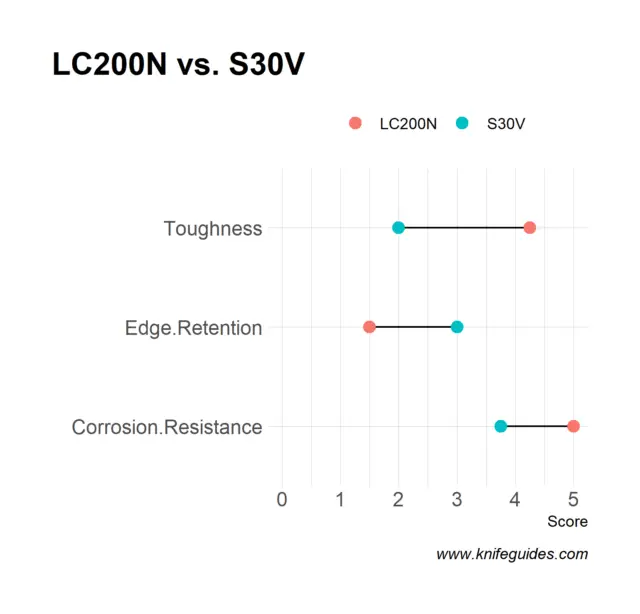

LC200N vs. S30V

S30V is harder and wins over the European steel in edge retention. However, LC200N is easier to sharpen and better at corrosion resistance than S30V.

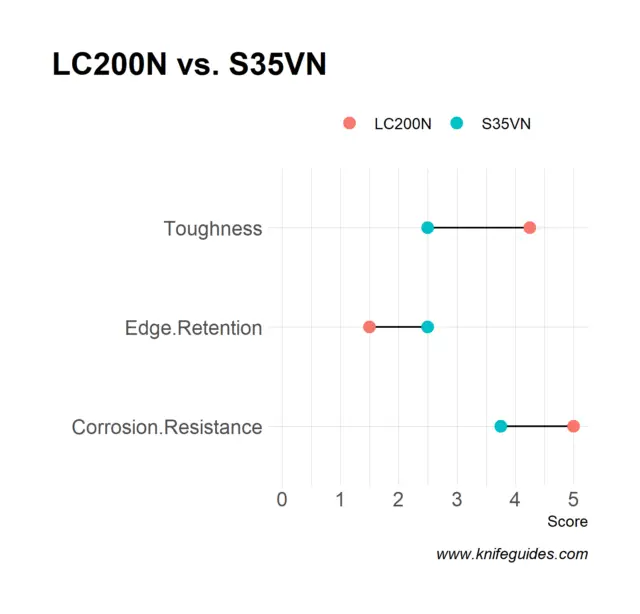

LC200N vs. S35VN

S35VN is an upgraded form of S30V. It holds a sharp edge better than LC200N. However, this European steel wins in toughness, ease of sharpening, and corrosion resistance.

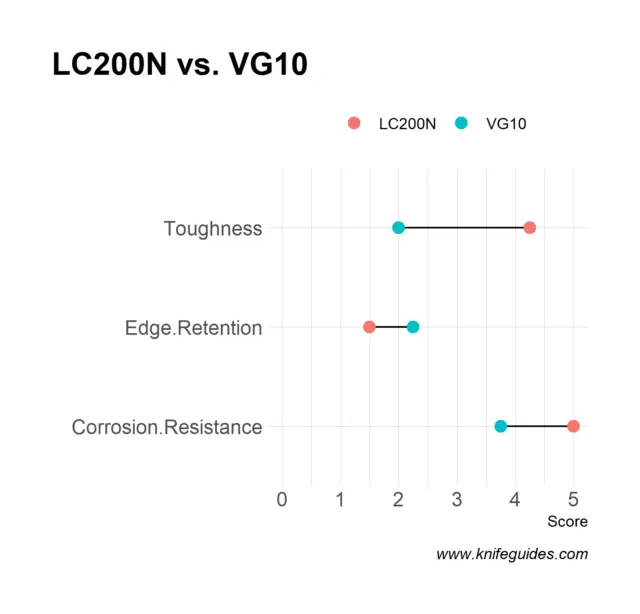

LC200N vs. VG10

VG10, the Japanese steel, is harder and better at edge retention. However, in all other aspects, LC200N is ahead.

So, is LC200N a Good Knife Steel?

The extremely high level of corrosion resistance and great edge retention power makes LC200N ideal for making knife blades for saltwater, kitchen, and humid conditions.

Hi, I am Jay. I am the creator of Knife Guides, your one-stop site for everything related to knives. I am a computer engineer by profession, knife aficionado by passion. Here I work with a group of people who’ve always had a passion for knives and blades. Over the years we’ve kind of become experts and decided to share our knowledge and ideas. I am also an avid hiker and enjoy offshore gamefishing.